OM-273473 Page 17

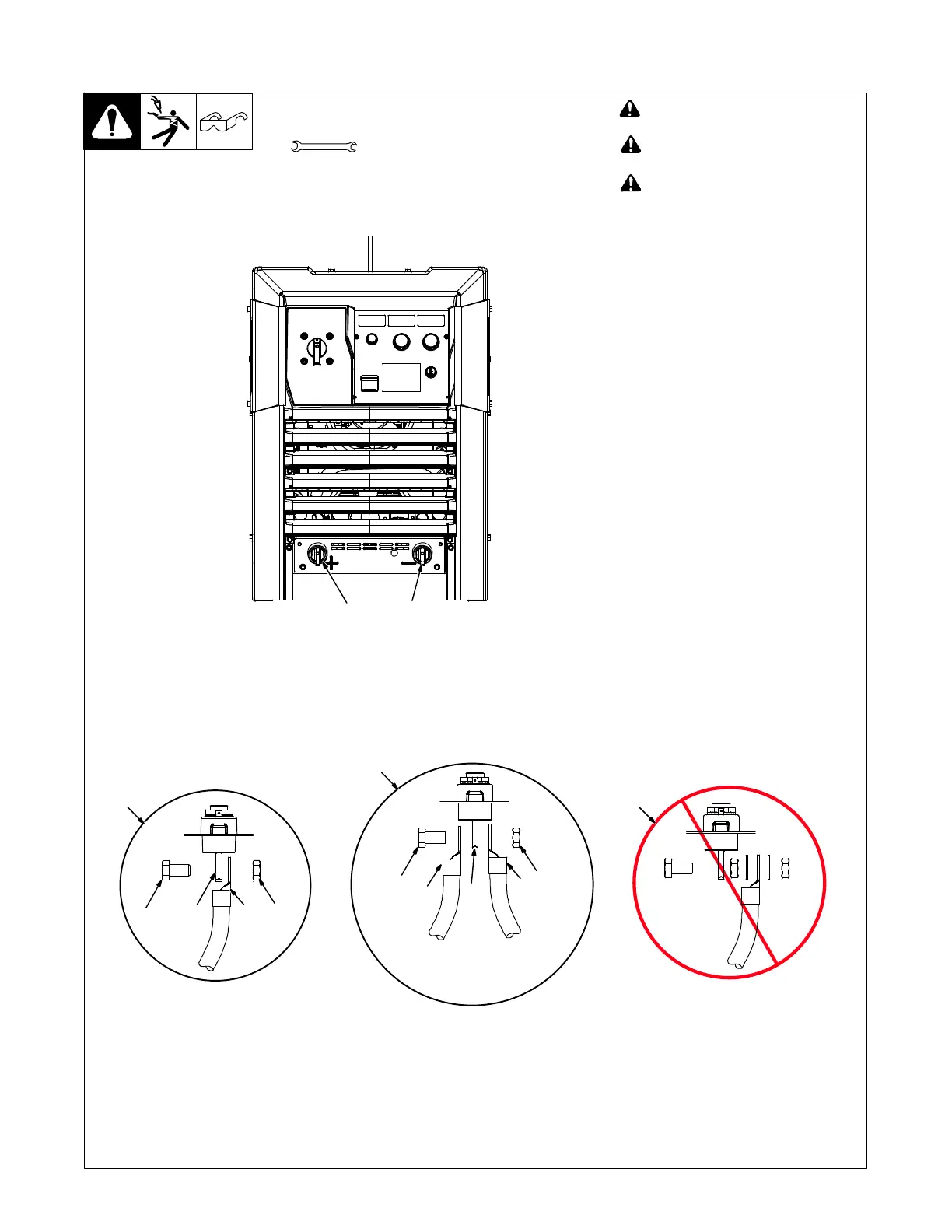

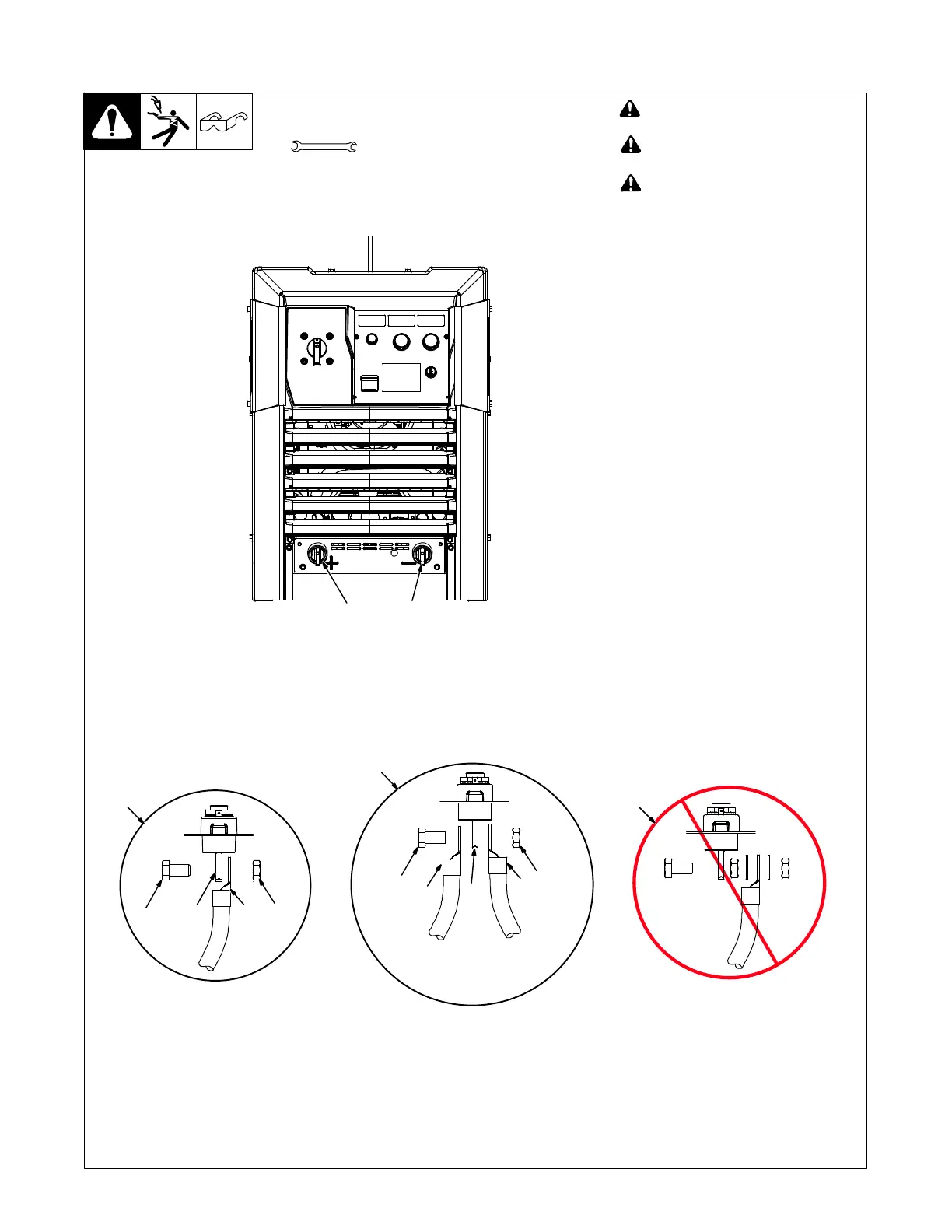

5-3. Connecting Weld Output Cables

XX

! Turn off power before connecting to

weld output tabs or receptacles.

! Do not use worn, damaged, under-

sized, or repaired cables.

! Failure to properly connect weld

cables may cause excessive heat

and start a fire, or damage your

machine.

Ensure all connections are tight.

Tab Connection

. Do not place anything between weld

cable terminal and output tab. Make

sure that the surfaces of the weld cable

terminal and output tab are clean.

1 Negative (−) Output Terminal

2 Positive (+) Output Terminal

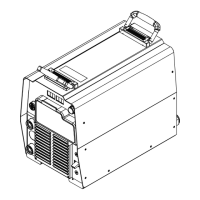

3 Correct Weld Cable Connection For

Single Feeder

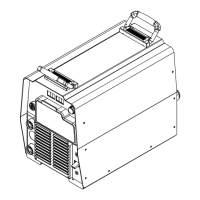

4 Correct Weld Cable Connection For

2/0 And Larger Double Cables

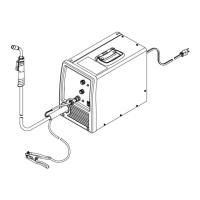

5 Incorrect Weld Cable Connection

6 Weld Output Terminal Bolt

7 Nut

8 Weld Cable Terminal

9 Output Terminal

Remove supplied nut and bolt from weld

output terminal. Insert bolt through hole in

weld cable terminal and hole in weld output

terminal. Screw nut onto bolt until weld

cable terminal is tight against output termi-

nal. Torque to 45-55 ft lb (61-75 N·m).

Tools Needed:

6

3

789

5

3/4 in. (19 mm) for output

terminal type connection

6

4

7

8

9

8

2/0 and larger double cables

2

Front View

1

Loading...

Loading...