OM-273473 Page 34

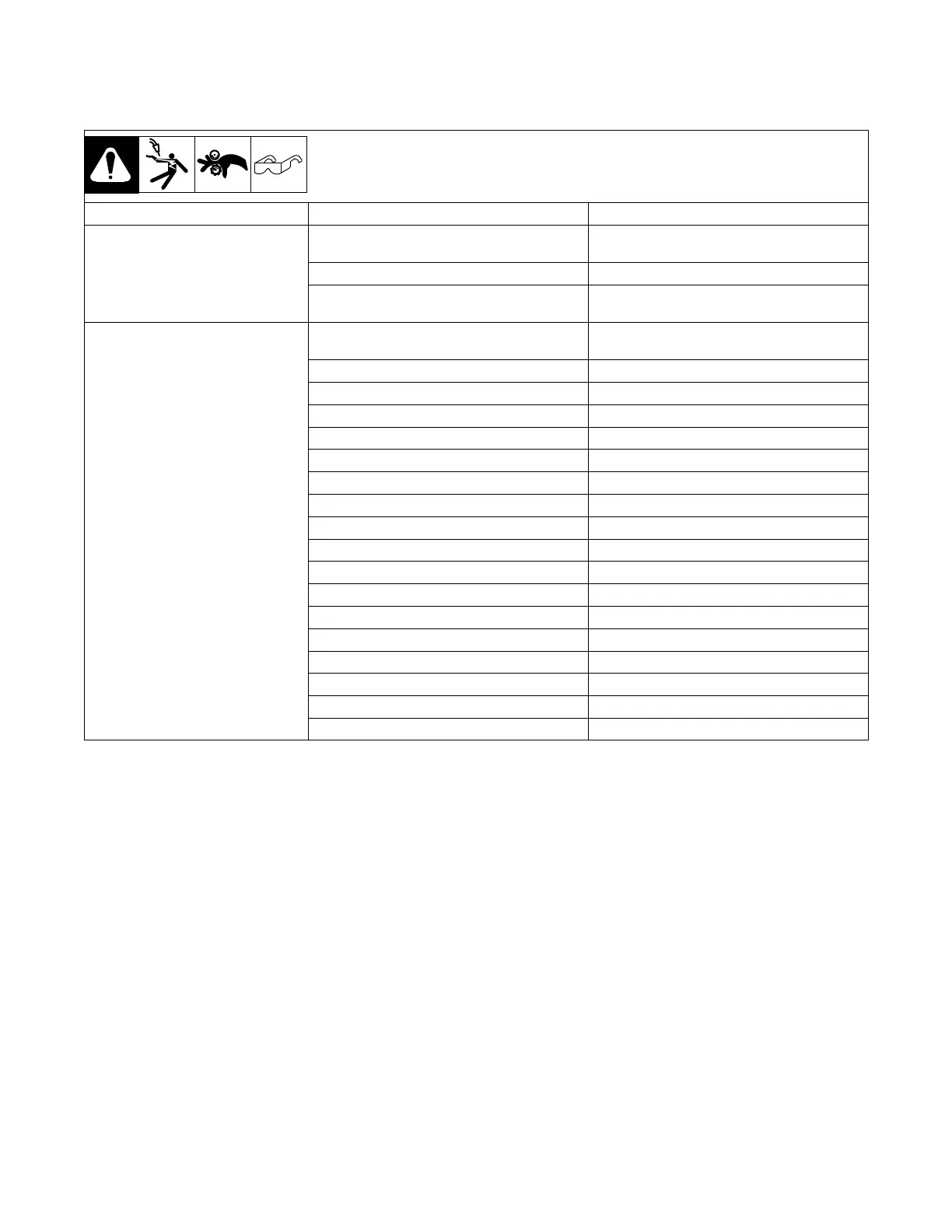

6-8. Basic Welding Troubleshooting

Listed below are some problems, causes and remedies related to welding operations; however, this list does not contain every possible condition that

could be encountered in welding.

Trouble Probable Cause Remedy

No weld output; unit completely

inoperative.

Line disconnect switch in Off position. Place switch in On position.

Power source switch in Off position. Place switch in On position.

Primary power fuse blown or circuit breaker

tripped.

Replace fuse or reset circuit breaker and check in-

put voltage.

Weld output is present, but wire stop

feeding while welding.

Wire feeder protective fuse blown or circuit breaker

tripped.

Replace fuse or reset circuit breaker and find over-

load condition.

Wire feeder drive rolls misaligned. Align drive rolls.

Wrong size drive rolls. Replace with proper size drive rolls.

Too much or too little drive roll pressure. Adjust drive roll pressure.

Too much tension set at wire spool. Reduce wire spool tension.

Restriction in unspooler or drum adapter. Replace unspooler or repair restriction.

Feeder motor burnt out. Test motor and replace if necessary.

Gun liner dirty or restricted. Remove gun liner and clean or replace.

Wrong type or size of liner. Install proper size liner.

Broken or damaged gun or torch. Replace faulty parts.

Contact tip opening restricted. Replace contact tip.

Wrong size or type of contact tip. Replace with proper size and type contact tip.

Sharp bends or kinks in gun cable or liner. Straighten gun cable and/or replace liner.

Gun overheating. Use gun with proper amperage rating.

Wrong size wire. Match wire size to liner and contact tip.

Guides rubbing on drive rolls. Adjust or position guides properly.

Drive rolls jammed. Remove foreign object from gears.

Motor cable disconnected or damaged. Connect, repair or replace motor cable.

Loading...

Loading...