OM-273473 Page 35

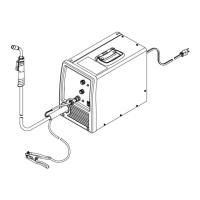

Trouble RemedyProbable Cause

Porosity in weld. Dirty base metal, heavy oxides, mill scale, oil, etc. Clean base metal by brushing, grinding or use

chemical cleansing before welding.

Regulator/flowmeter faulty. Adjust or replace regulator/flowmeter.

Gas cylinder valve closed. Open gas cylinder valve.

Gas regulator diaphragm defective. Replace regulator.

Flowmeter cracked or broken. Repair or replace flowmeter.

Gas hose disconnected or leaking. Connect or replace gas hose.

Too much or too little gas flow. Adjust for proper gas flow.

Moisture in shielding gas. Replace gas cylinder or supply.

Wrong gas for wire type or transfer mode. Use correct shielding gas.

Feeder gas solenoid faulty. Replace solenoid.

Gun or outlet cable leaking. Repair or replace faulty parts.

Wire feed speed setting too high. Reduce wire feed speed.

Contact tip extends too far out of nozzle. Adjust or replace parts (max distance should not

exceed 1/8 in (3.2 mm).

Nozzle to work distance too large. Reduce nozzle to work distance.

Incorrect gun or torch angle. Set proper gun angle (porosity or dirty welds mean

gun angle is too large).

Nozzle restriction. Clean off spatter or remove restriction.

Breeze or drafts in weld zone. Shield weld zone from drafts.

Low shielding gas cylinder pressure. Replace gas cylinder.

Gas leak at gun to feeder connection. Properly install gun or replace O-rings at gun

connector.

Excessive spatter. Voltage set too high. Reduce voltage setting (reduce trim or arc adjust

for pulse welding).

Incorrect gun or torch angle. Set proper gun angle.

Too much or too little gas flow. Adjust for proper gas flow.

Wrong gas for wire type or transfer mode. Use correct shielding gas.

Wrong electrode wire type or size. Use proper electrode wire.

Wrong inductance setting. Adjust inductance.

Electrode wire dirty or old. Replace with new electrode wire.

Oily or dirty base metal. Clean base metal by brushing, grinding or use

chemical cleansing before welding.

Excessive wire stick-out or nozzle to work distance

too great.

Adjust wire stick-out or reduce nozzle to work

distance.

Wrong transfer mode. Set proper transfer mode.

Travel speed too slow. Increase travel speed so that arc is on leading edge

of weld puddle.

Loading...

Loading...