OM-273473 Page 32

6-6. 30 Points Of Mechanics In MIG Welding

30 Pts MIG − 2014-09

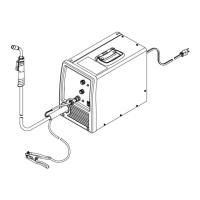

Primary Power

S Check primary power connection at line disconnect switch or receptacle and/or cord plug.

S Check primary power connection at welding power source.

Secondary Power

S Check secondary weld output connections at welding power source.

S Inspect condition and routing of positive weld cable to wire drive motor.

S Check connection of positive weld cable to wire drive motor.

S Inspect condition and routing of negative weld cable to fixture.

S Check connection of negative weld cable to fixture.

S Inspect condition of any rotary grounds, grounding shoes or other auxiliary grounds.

S Check installation, routing and condition of welding gun.

Shielding Gas

S Check gas hose connection to shielding gas supply regulator.

S Check shielding gas flow rate.

S Check gas hose routing.

S Check gas hose connection at wire drive housing.

S Check gun connection at wire drive and be sure O−rings seal at drive housing.

S Check condition of gas diffuser.

S Check condition of nozzle.

S Check O-ring for proper sealing at nozzle.

Welding Wire

S Inspect condition of de-reeler. Check for wear at quick-connect coupling and replace if necessary.

S Check placement of payoff pack or drum for smooth feed path.

S Inspect condition and routing of input conduit.

S Check installation of quick-connect coupling at rear of wire drive so that it does not contact drive rolls. Check for wear and replace if necessary.

S Check drive rolls and replace if worn.

S Check for drive roll tension setting.

S Check intermediate guide for proper size to match wire size and replace if worn.

S Check for proper length of liner at both ends and be sure it is cut without burrs.

S Check liner for proper size to match wire size.

S Check liner for wear and clean out to prevent plugging.

S Check contact tip for proper size to match wire size.

S Check contact tip for wear and change at regular intervals.

S Check contact tip for a tight fit and secure installation at gun.

Loading...

Loading...