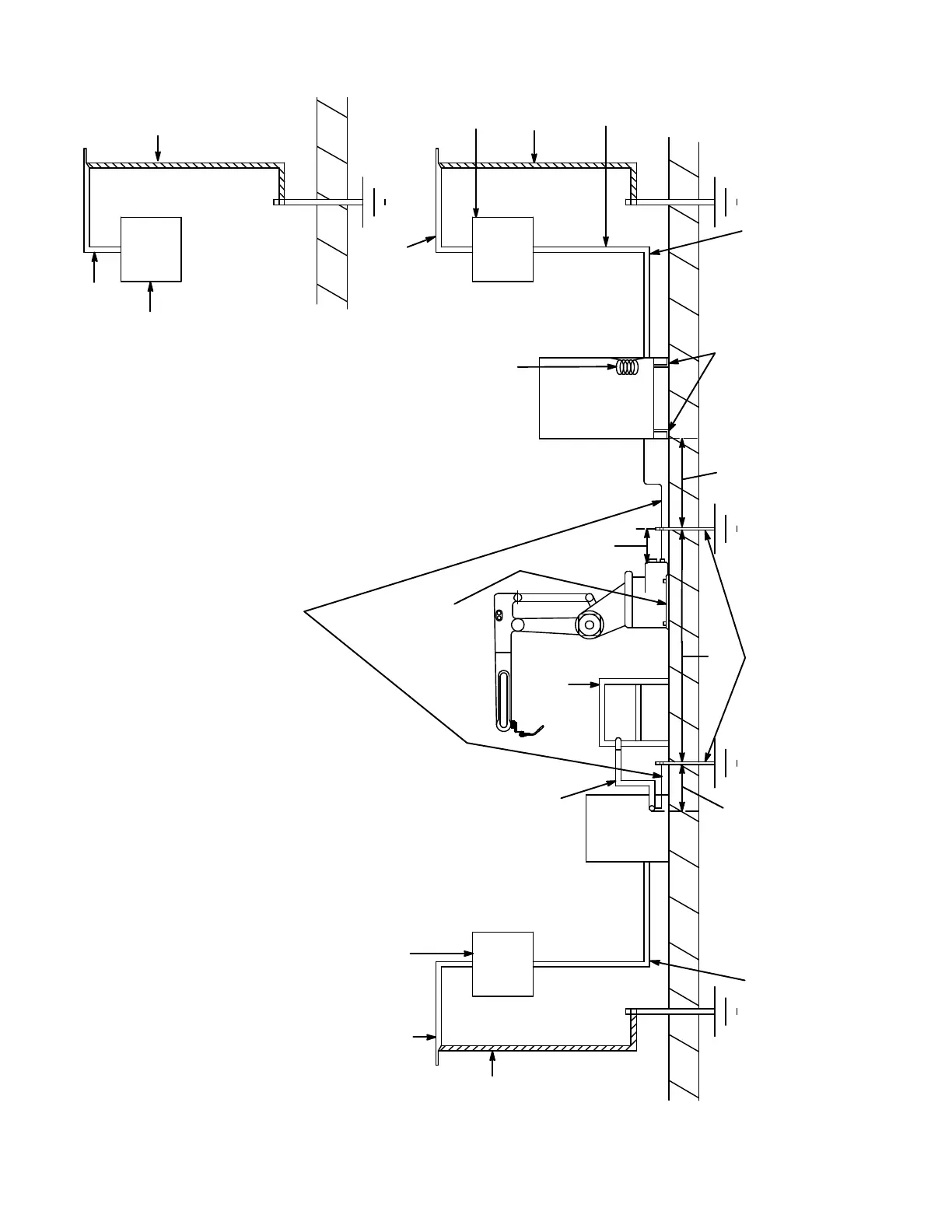

OM-273473 Page 31

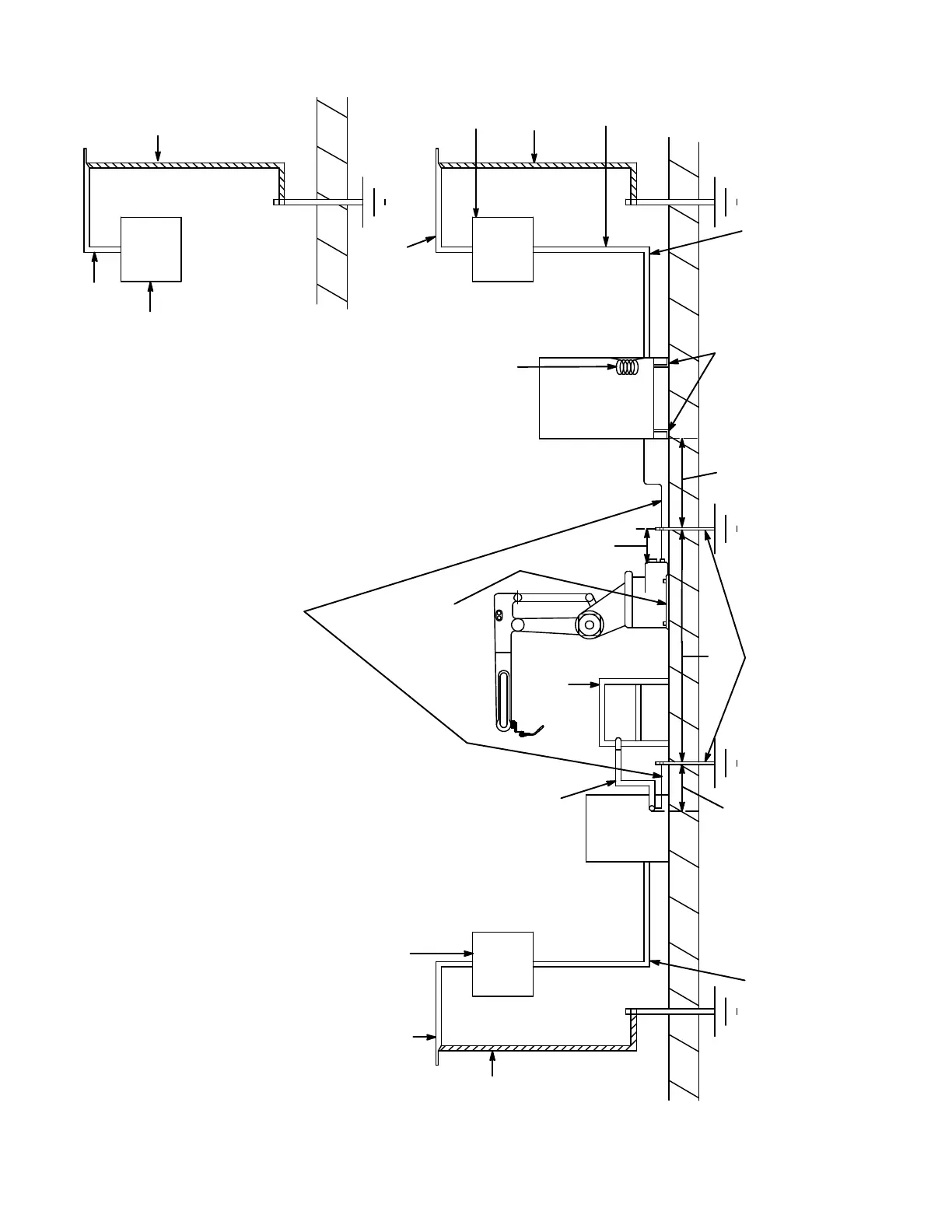

Existing

Input Power

Supply

Ground

Robot

Control

Welding

Power

Source

Input Power

Supply Line

Line

Disconnect

Switch Box

Use Proper Size Input And Ground

Insulating Liner

Strips Under Both

Support Channels

Customer Supplied Driven Ground Rod

Or Separate Earth Ground Connection

Less Than 100 Ohms To Building Ground

Existing

Input Power

Supply Ground

Input Power

Supply Line

Line Disconnect Switch Box

For Input Power To Fixture

Positioning And Peripheral

Equipment

Input Power

Supply Line

Line

Disconnect

Switch Box

If Using

Conduit,

Isolate It

From Robo

Control

Cabinet

Existing

Input Power

Supply Groun

Make Ground

Lead 5 ft. (1.5 m)

To 10 ft. (3 m) Longer

And Coil It Inside

Robot Control

10 ft. (3 m)

Minimum

Work Weld

Cable

Worktable

Make Separate Equipment

Earth Ground Using A Minimum

Of No. 3 Gauge Copper Braided

Cable That Provides A Resistance

Value Less Than 100 Ohms Between

The Component Connection And

The Ground Wire

5 ft.

(1.5 m)

15 ft.

(4.5 m)

5 ft.

(1.5 m)

IMPORTANT: DO NOT mount anything to robot control cabinet.

SB-136 221-

Insulating

Plate

Under Robot

Conductors For The Input Power

Supply Line Voltage

Use Proper Size Input And Groun

Conductors For The Input Powe

Supply Line Voltage

Figure 9-1. Earth Ground Connections To Stationary Robot System Components

Loading...

Loading...