OM-245 849 Page 29

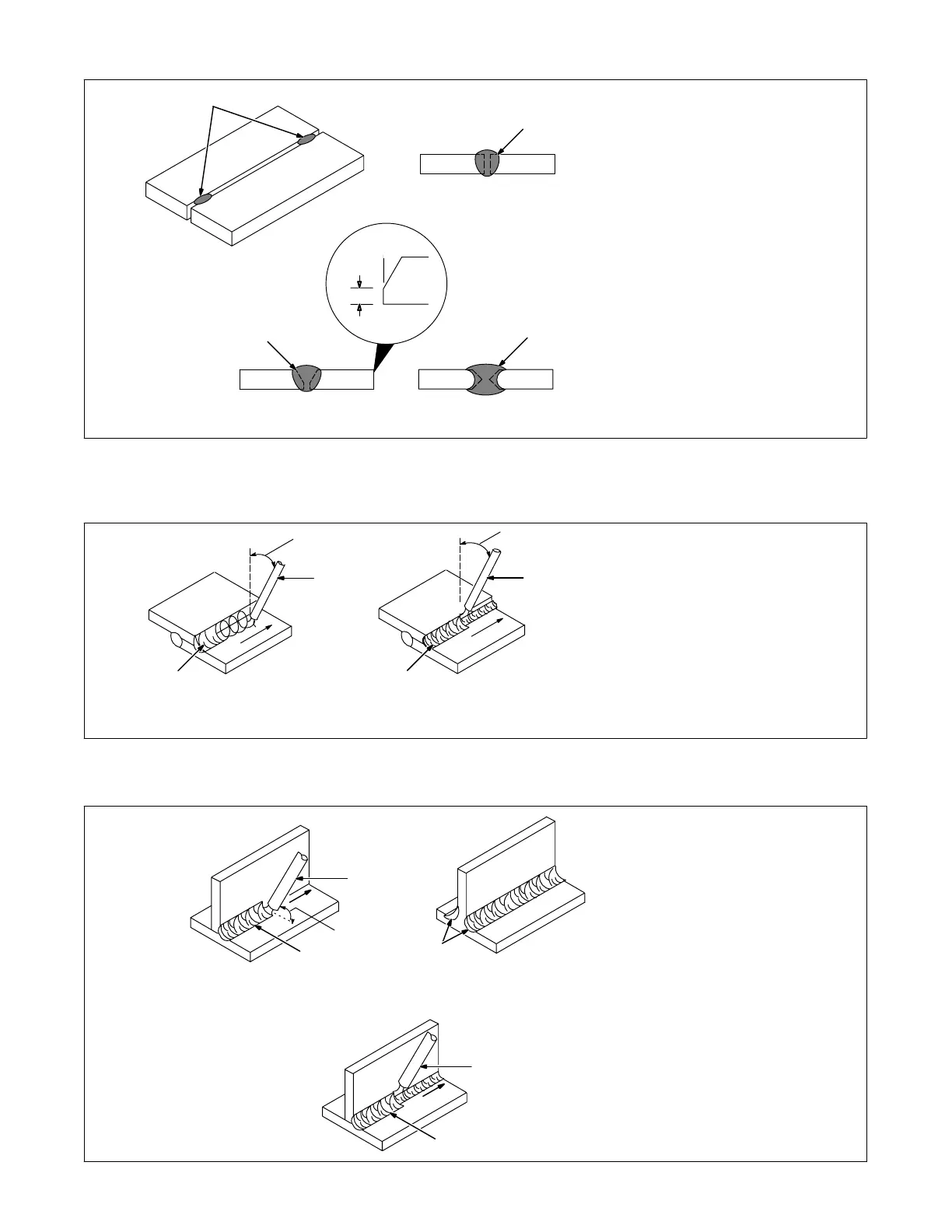

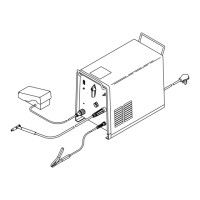

11-10. Butt Joints

S-0662

1 Tack Welds

Prevent edges of joint from draw-

ing together ahead of electrode by

tack welding the materials in posi-

tion before final weld.

2 Square Groove Weld

Good for materials up to 3/16 in (5

mm) thick.

3 Single V-Groove Weld

Good for materials 3/16 − 3/4 in

(5-19 mm) thick. Cut bevel with

oxyacetylene or plasma cutting

equipment. Remove scale from

material after cutting. A grinder

can also be used to prepare bev-

els.

Create 30 degree angle of bevel

on materials in V-groove welding.

4 Double V-Groove Weld

Good for materials thicker than

3/16 in (5 mm).

30°

2

1

1/16 in

(1.6 mm)

3

4

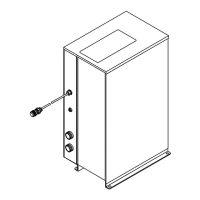

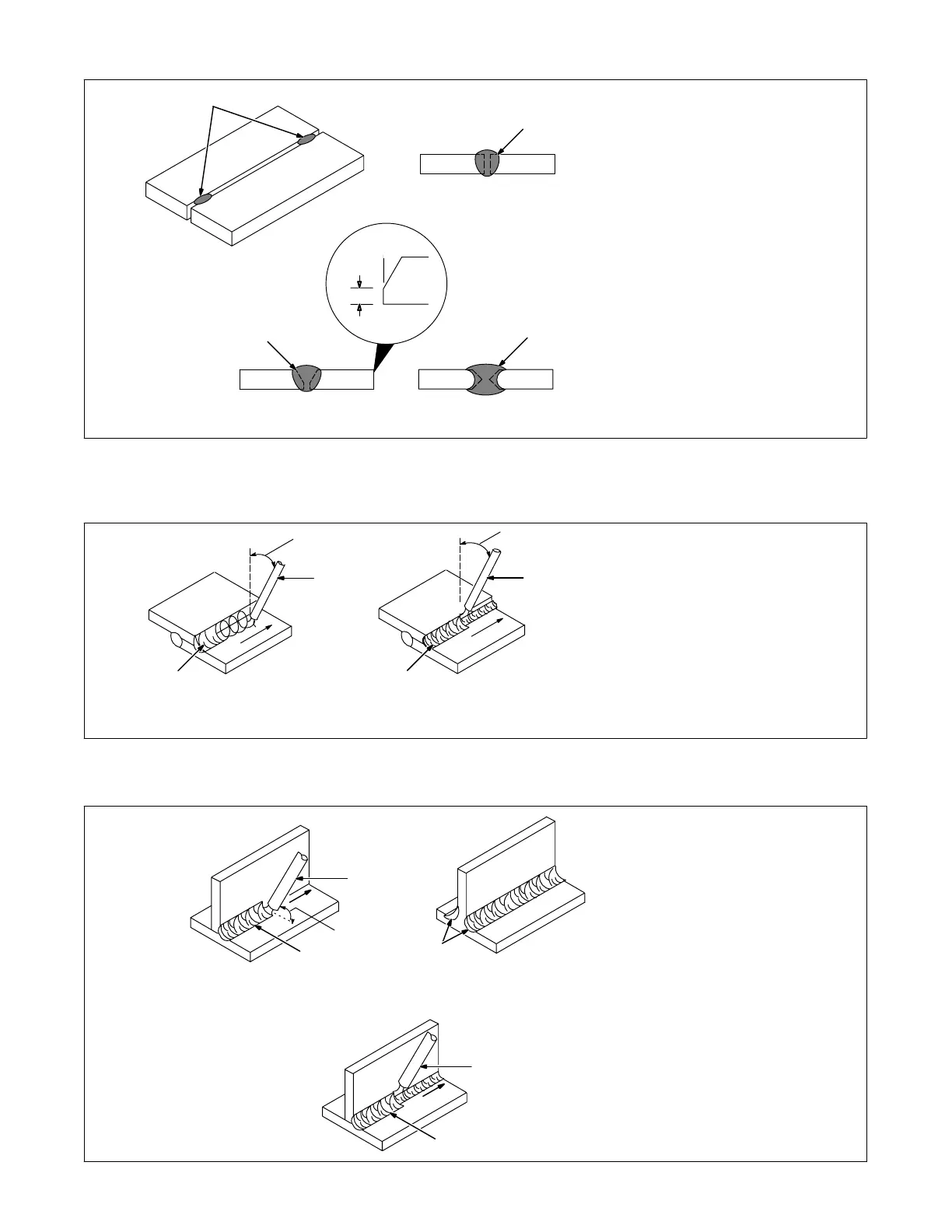

11-11. Lap Joint

S-0063 / S-0064

1 Electrode

2 Single-Layer Fillet Weld

Move electrode in circular motion.

3 Multi-Layer Fillet Weld

Weld a second layer when a heavi-

er fillet is needed. Remove slag

before making another weld pass.

Weld both sides of joint for maxi-

mum strength.

30°

Or Less

Single-Layer Fillet Weld

Multi-Layer Fillet Weld

30°

Or Less

1

1

2

3

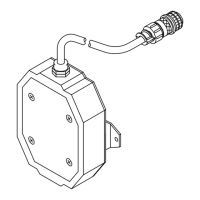

11-12. Tee Joint

S-0060 / S-0058-A / S-0061

1 Electrode

2 Fillet Weld

Keep arc short and move at defi-

nite rate of speed. Hold electrode

as shown to provide fusion into the

corner. Square edge of the weld

surface.

For maximum strength weld both

sides of upright section.

3 Multi-Layer Deposits

Weld a second layer when a heavi-

er fillet is needed. Use any of the

weaving patterns shown in

Section 11-9. Remove slag before

making another weld pass.

45°

Or

Less

1

2

1

3

2

Loading...

Loading...