Cutting out Data with Register Marks

4-21

4

Extended Functions – Cutting –

Adjust the Sensitivity (Light Intensity) of the Mark Sensor LED (Automatically)

If an error occurs frequently in register mark detection, a possible cause is an improper sensitivity of the mark

sensor LED. In this case, adjust the sensitivity (light intensity) of the mark sensor LED.

1

Make sure that the machine is in cutting mode.

• If the machine is in printer mode, press the key to

switch the mode to cutting mode.

2

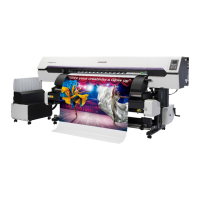

Confirm that the mark sensor is located just above a

plain area (non-printed area) of the medium.

• If the mark sensor is not located just above a plain area,

correct the location by pressing .

3

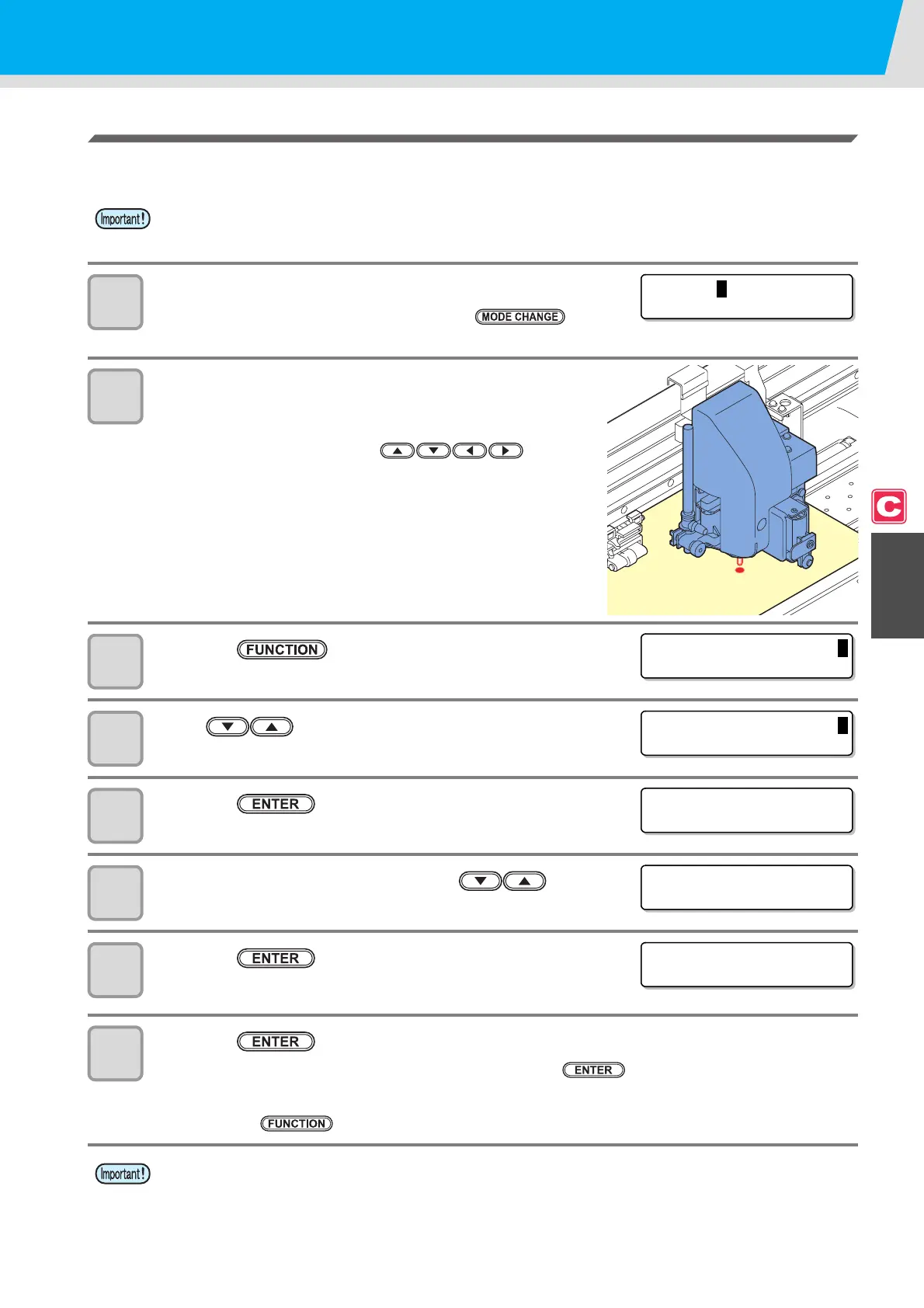

Press the key.

4

Press to select [MAINTENANCE].

5

Press the key twice.

6

Select [LEVEL ADJUST] by pressing .

7

Press the key.

8

Press the key after the number displayed on the screen is stabilized.

• If all digits of the number cannot be stabilized, press the key when the leftmost digit of the

number is fixed.

• The adjusted value is registered and the machine returns to LOCAL.

• Pressing the key enables you to move the cutter unit manually.

• Make sure that the medium is clean and white, and locate the medium directly under the sensor.

• The value registered in [LEVEL ADJUST] will not be initialized even if the procedure described in P. 4-

37 "Initializing the Settings" is performed.

<LOCAL .

C

> [ #01 ]

CUT 1 ( 3 0 / 6 0 / 0 . 3 0 )

FUNCT I ON

C

SETUP <ENT>

FUNCT I ON

C

MA I N T ENANCE < EN T >

MARK S ENSOR

SENSOR CHECK <e n t >

MARK S ENSOR

LEVEL ADJUST <en t >

LEVEL ADJUST

OUT: **** IN: ****

Loading...

Loading...