73 / 174

Service Manual Mitsubishi SQ-Series diesel engines

Version 08/2004

PISTONS, CONNECTING RODS,

CRANKSHAFT AND CRANKCASE

ENGLISH

ENGINE MAIN PARTS

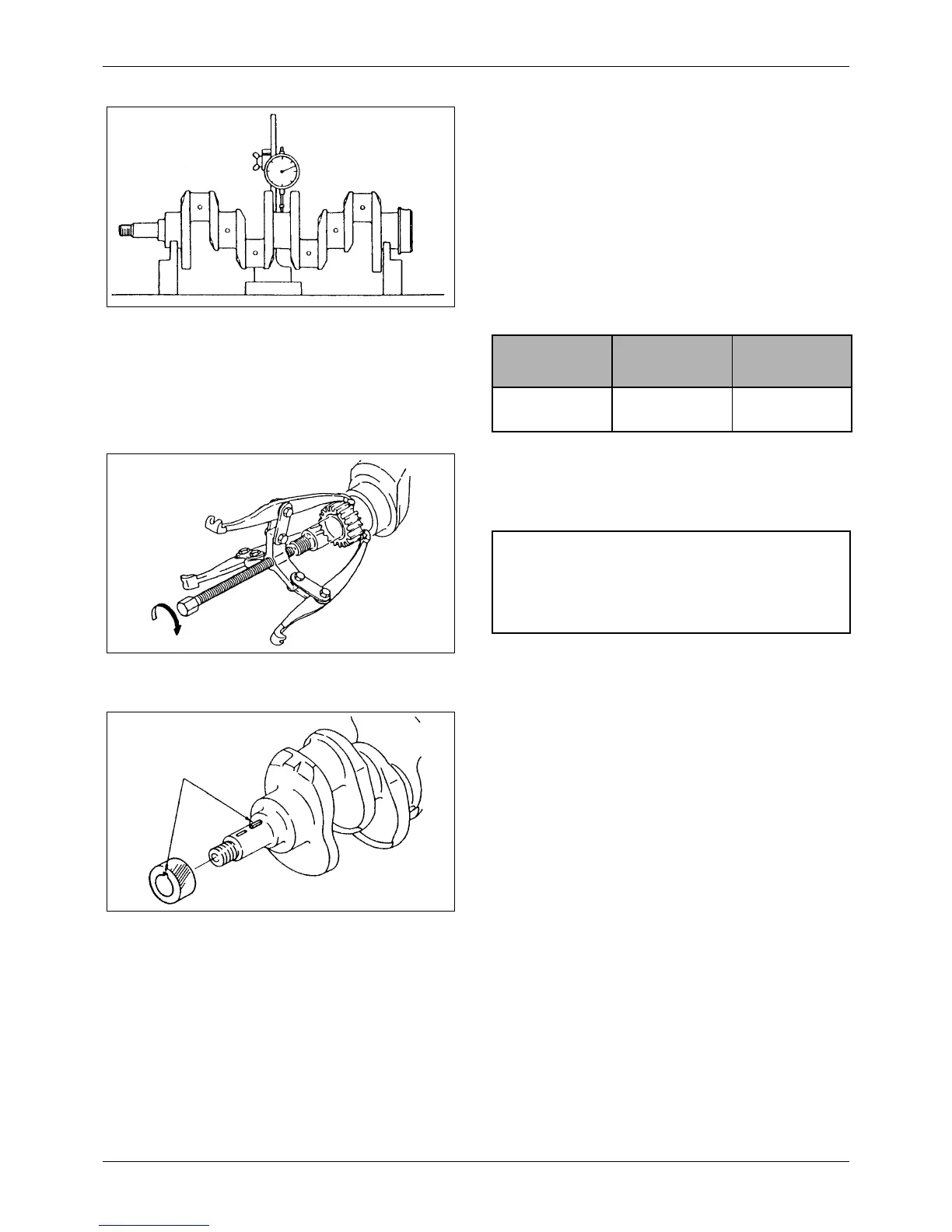

4. Checking crankshaft deflection

Support the crankshaft on its front and rear

journals in V-blocks. With the dial indicator set at

0.00 mm [0.0000 in.] at the center journal, turn the

camshaft full one revolution and read the indicator,

as shown in the illustration. If deflection is out of

the assembly standard but does not exceed the

repair limit, repair the crankshaft by grinding. If

deflection exceeds the repair limit, repair the

crankshaft by cold working. Replace the crankshaft

if runout exceeds the repair limit excessively.

Unit: mm [in.]

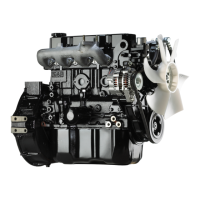

5. Removing crankshaft gear

Remove the crankshaft gear with a gear puller, as

shown in the illustration.

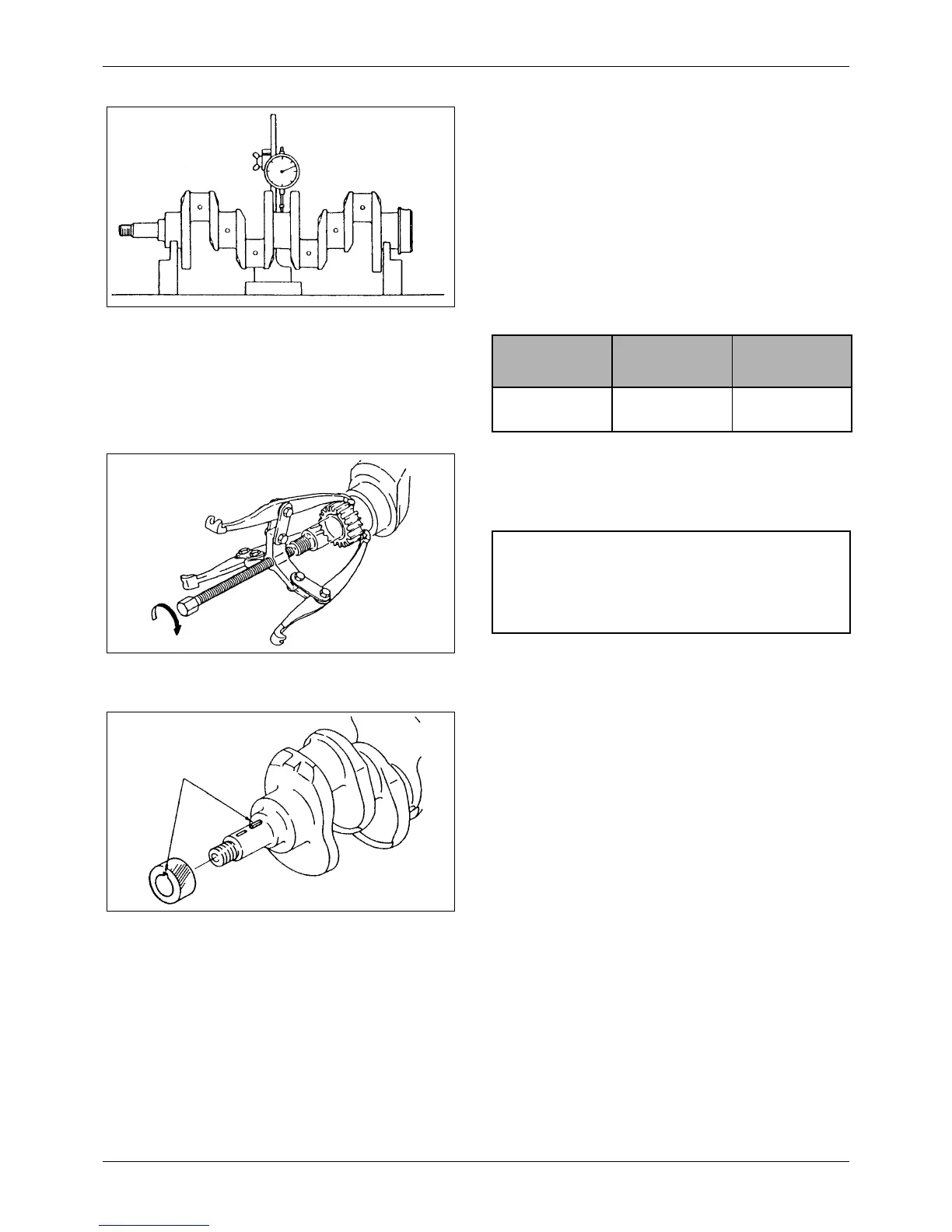

6. Installing crankshaft gear

1) Heat the gear in an oven to a temperature of

100°C to 150°C [212°F to 302°F].

2) Install the key to the crankshaft.

3) Install the gear by fitting the key into the

keyway in the gear.

Figure 128 Checking crankshaft deflection

Item

Assembly

Standard

Repair Limit

Crankshaft

deflection

0.02 [0.0008] or

less

0.05

[0.0020]

Figure 129 Removing crankshaft gear

NOTE

Do not remove the gear unless it requires

replacement.

Figure 130 Installing crankshaft gear

Fit key into keyway

Loading...

Loading...