74 / 174

Service Manual Mitsubishi SQ-Series diesel engines

Version 08/2004

ENGLISH

PISTONS, CONNECTING RODS,

CRANKSHAFT AND CRANKCASE ENGINE MAIN PARTS

10.2.4 Crankcase

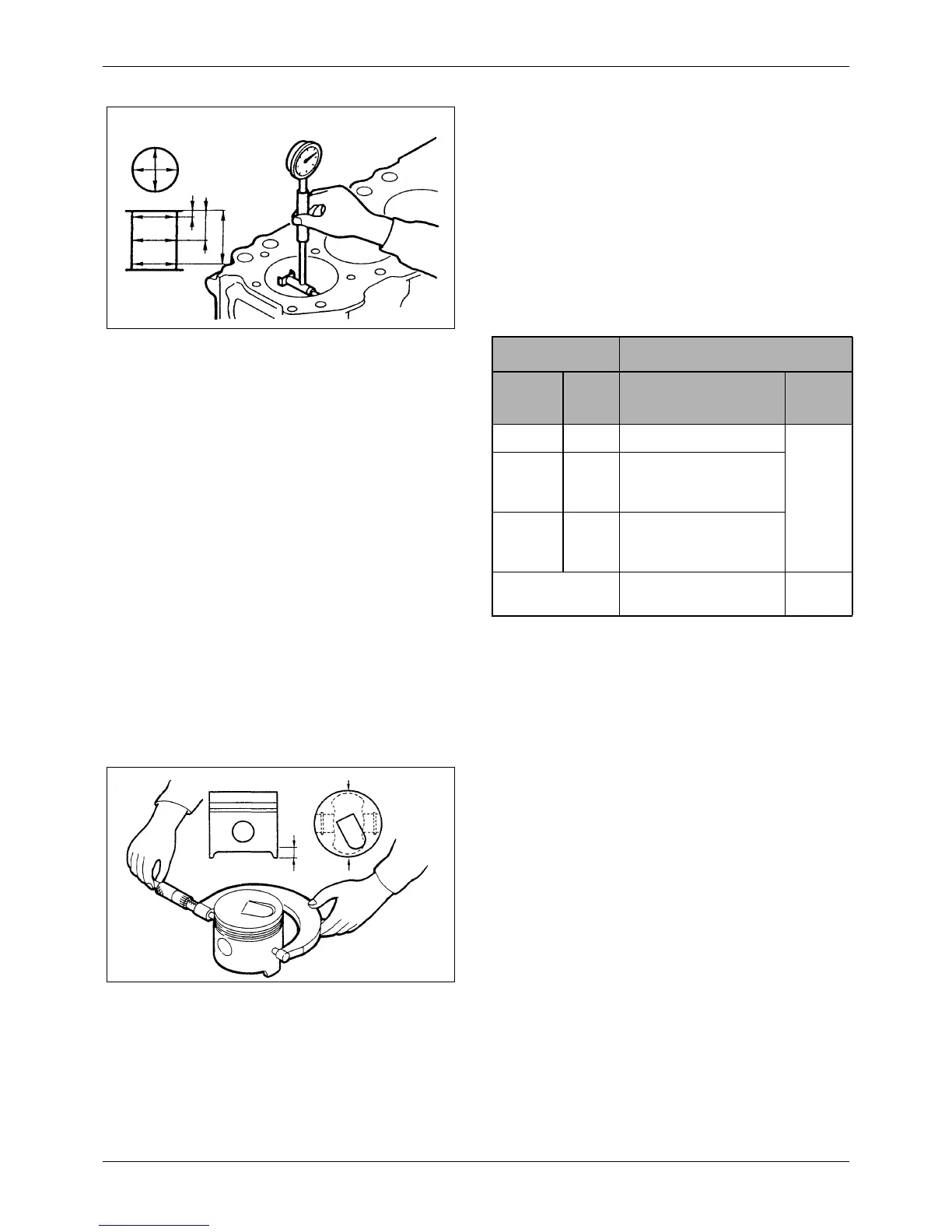

1. Checking crankcase bore

1) Measure the entire bore with a cylinder bore

gage having a dial indicator. Take

measurements at A, B and C positions in the

bore on axes 90° apart, as shown in the

illustration, to check the diameter, out-of-

round and taper. If the bores exceeds the

service limit for diameter, out-of-round and

taper, increase them for oversize pistons.

Unit: mm [in.]

2) Boring of cylinders

a There are two piston oversizes (0.25 mm

[0.0098 in.] and 0.50 mm [0.0197 in.] over

standard size) as listed above. Determine the

piston size to be used based on the largest

bore diameter of the cylinders.

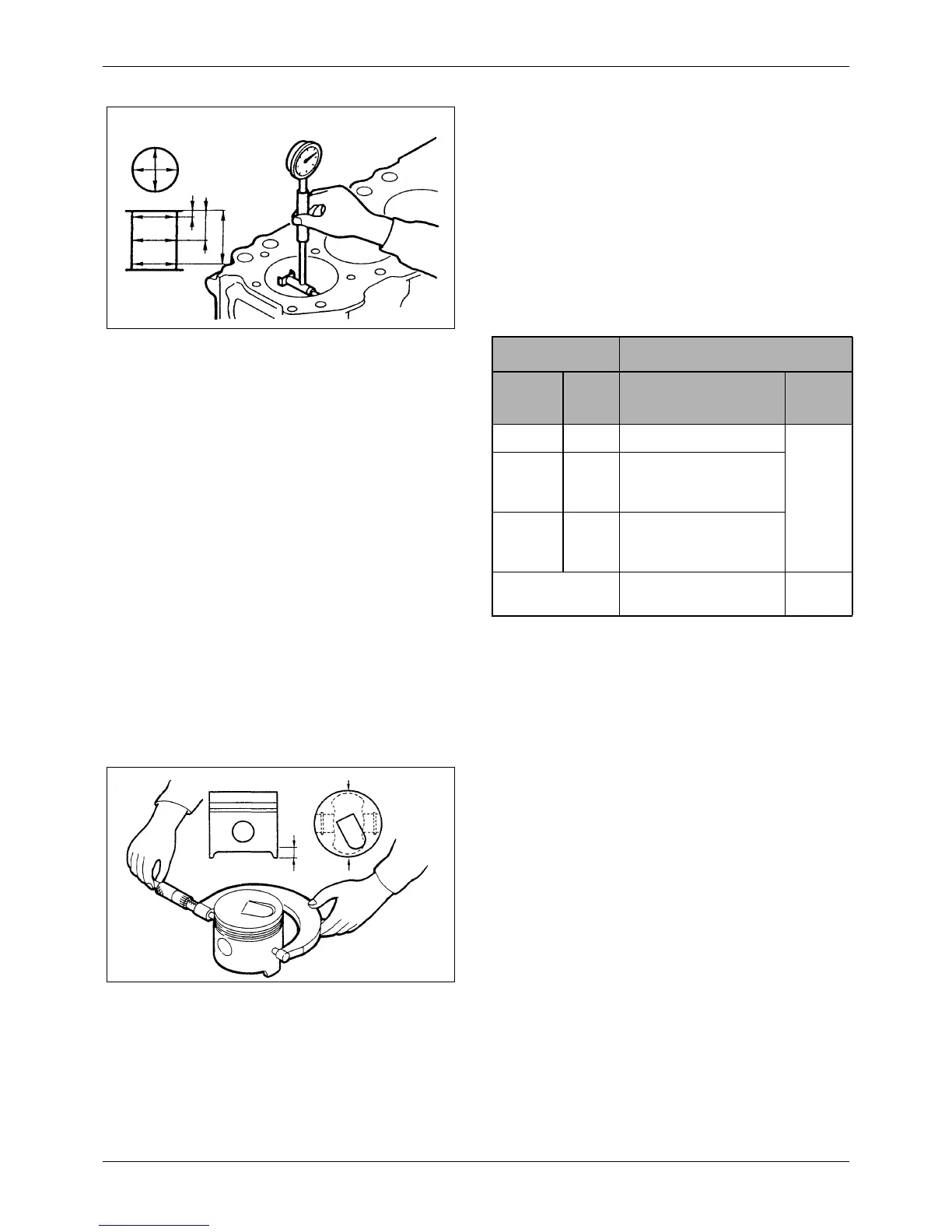

b Measure the outside diameter of the piston to

be used.

c Based on the measurement of the piston

outside diameter, calculate the finishing

dimension to be achieved by boring.

A : Measured piston outside diameter selected

oversized piston) mm

B : Clearance between piston and cylinder

(standard value) 0.03 mm [0.0012 in.]

C : Honing allowance 0.04 mm [0.0016 in.] or

less

Finishing dimension = A + B - C

Figure 131 Checking crankcase bore

Measuring

points

Measuring

directions

Piston available Bore Diameter

Size

Size

Code

Assembly Standard

Service

Limit

Standard STD 88 [3.46 ]

+0.2

[+0.008]

0.25

[0.0098]

oversize

25 88.25 [3.4744 ]

0.50

[0.0197]

oversize

50 88.50 [3.4842 ]

Out-of-round and

taper of bores

0.015 [0.0006] or less __

+0.035

0

+0.0014

0

+0.035

0

+0.0014

0

+0.035

0

+0.0014

0

Figure 132 Measuring piston diameter

14 mm

[0.55 in.]

Perpendicular

to piston pin

Loading...

Loading...