82 / 174

Service Manual Mitsubishi SQ-Series diesel engines

Version 08/2004

ENGLISH

PISTONS, CONNECTING RODS,

CRANKSHAFT AND CRANKCASE ENGINE MAIN PARTS

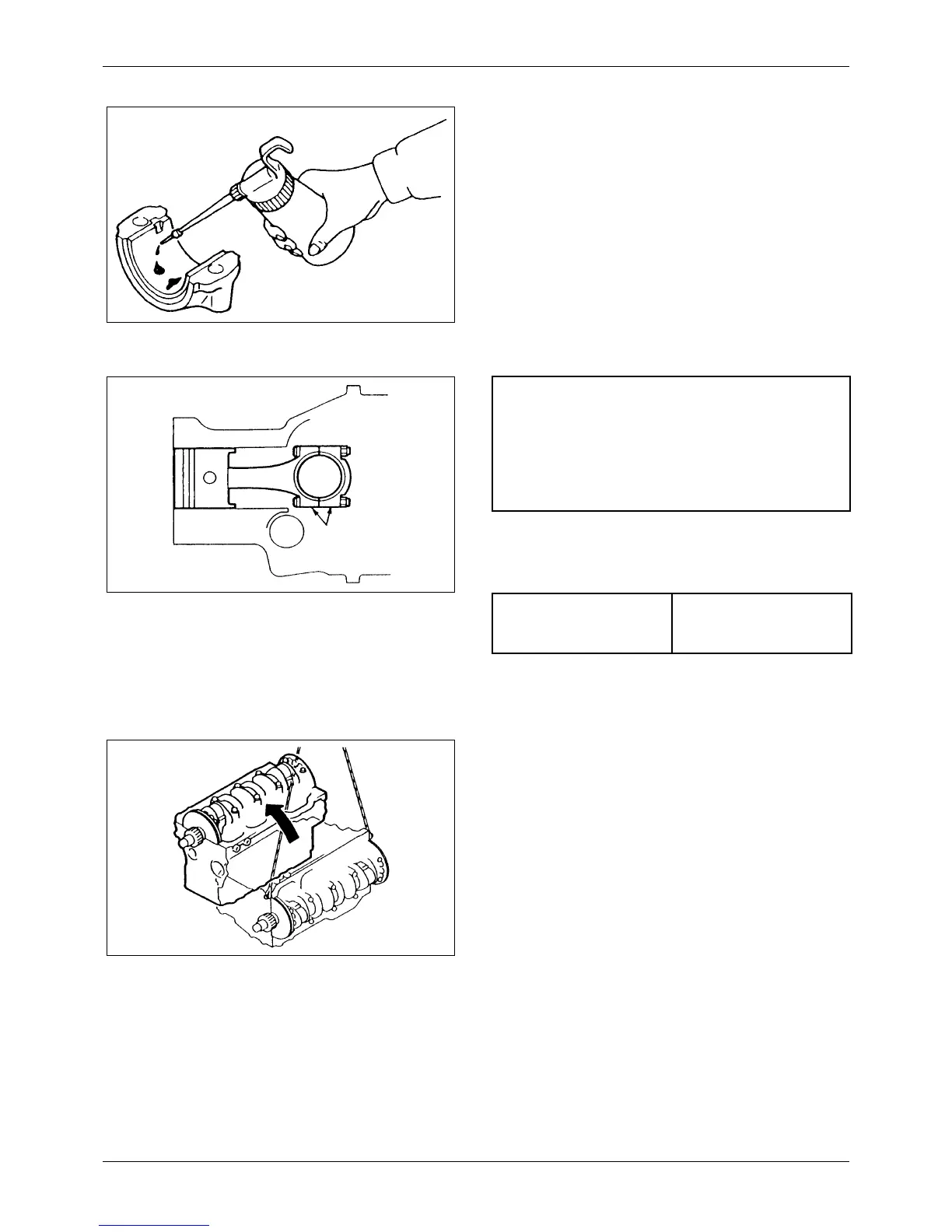

14. Installing connecting rod cap

1) Install the lower half of the connecting rod

bearing in the connecting rod cap. Make sure

the tab on the back of the bearing is in the

notch of the connecting rod cap. Apply engine

oil to the inside of the bearing.

2) Install the connecting rod cap (with the

bearing) to the connecting rod (over the

crankpin) with the matching mark of the cap

on the same side as the mark of the rod.

3) Tighten the connecting rod cap nuts finger

tight.

4) Tighten the connecting rod cap nuts evenly to

the specified torque with a torque wrench.

5) Check the thrust clearance of the connecting

rod big-end. If the thrust clearance is less than

the assembly standard, retighten the cap nuts.

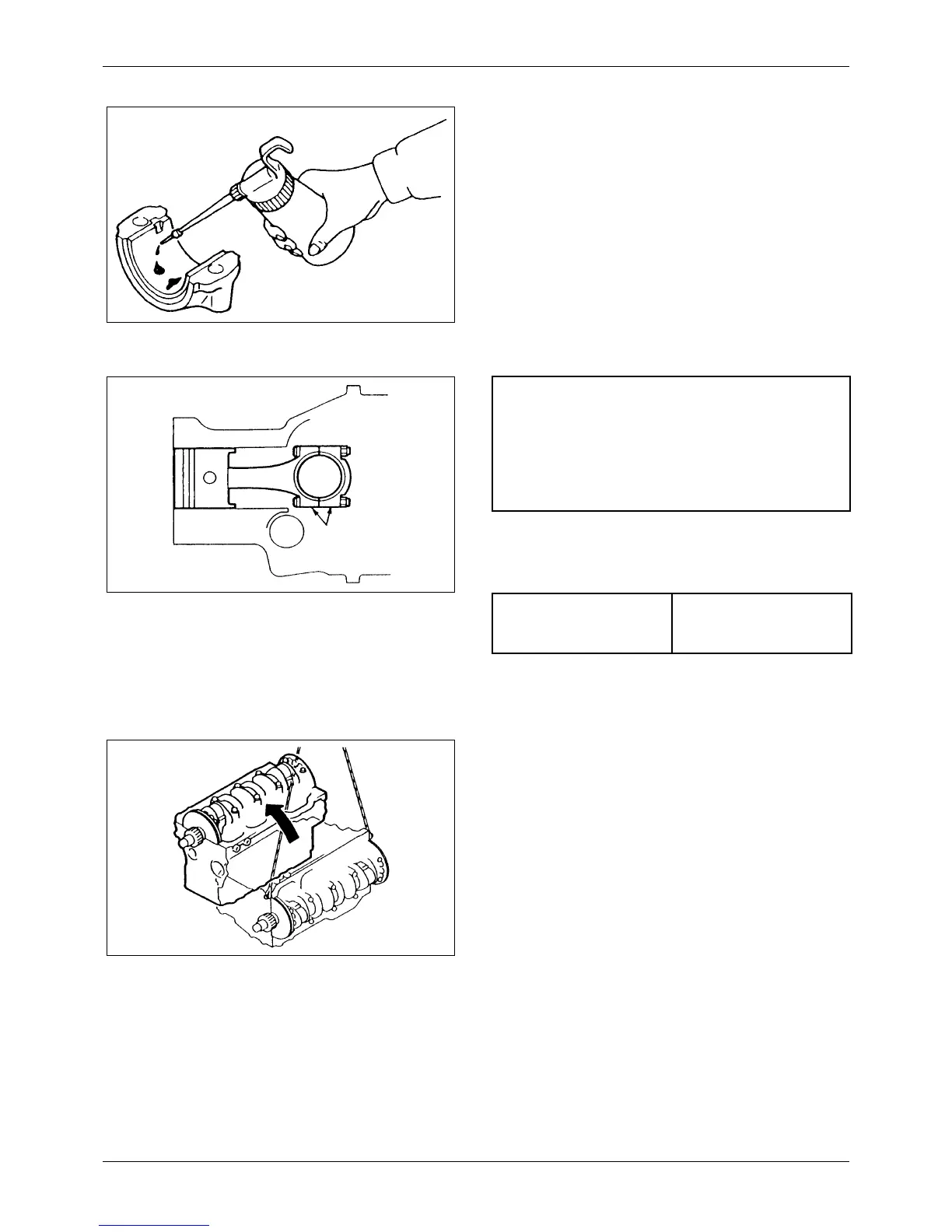

15. Raising crankcase

Raise up the crankcase with the oil pan side up.

Figure 153 Installing connecting rod cap (1)

Apply engine oil

Figure 154 Installing connecting rod cap (2)

Matching marks

NOTE

Steps (a) through (c) are for the installation of the

piston assemblies in the No.1 and No.4 cylinders.

Turn the crankshaft 180° and install the piston

assemblies in the No.2 and No.3 cylinders.

Tightening torque

54 ± 5 N·m

(5.5 ± 0.5 kgf·m)

[40 ± 4 lbf·ft]

Figure 155 Raising crankcase

Loading...

Loading...