The [TRIP POINTS] Key Cha

ter Four: Functional Overview

56

Hysteresis

Hysteresis is built into the operation of the two trip points to help compensate for the noise

inherent in all systems. Without hysteresis, the noise may cause the relays to repeatedly switch

states, a condition known as “relay chatter.” The amount of hysteresis can be adjusted separately

for each trip point.

Setting the hysteresis too high will create a

deadband

around the trip point. The deadband

prevents the trip point relay from responding to changes in the pressure signal around the trip

point. Ideally, the hysteresis should be close to, but not less than, the peak-to-peak noise. This

setting will provide maximum immunity from relay chatter while providing the best possible

accuracy. It may take some trial and error efforts to determine the smallest hysteresis setting

appropriate for your system to prevent relay chatter.

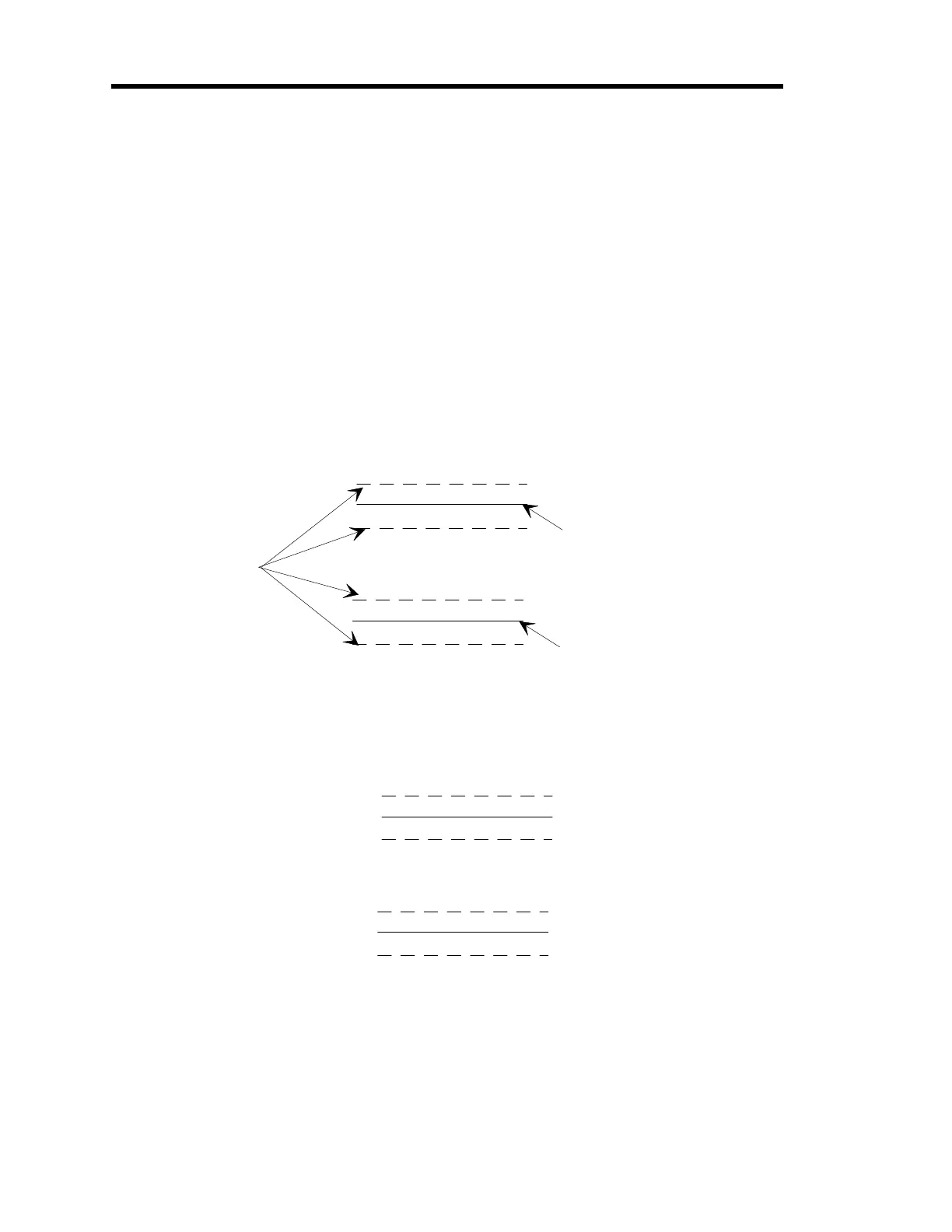

The hysteresis value is defined as a ±percent of the trip point value and can range from 0 to

10%. The 670 instrument adds the ± hysteresis value to the trip point value to create a hysteresis

band around the trip point, as shown in Figure 12.

Trip Point Hi

h Value

Trip Point Low Value

Hysteresis

Values

Figure 12: Hysteresis Bands Applied to the Trip Point Values

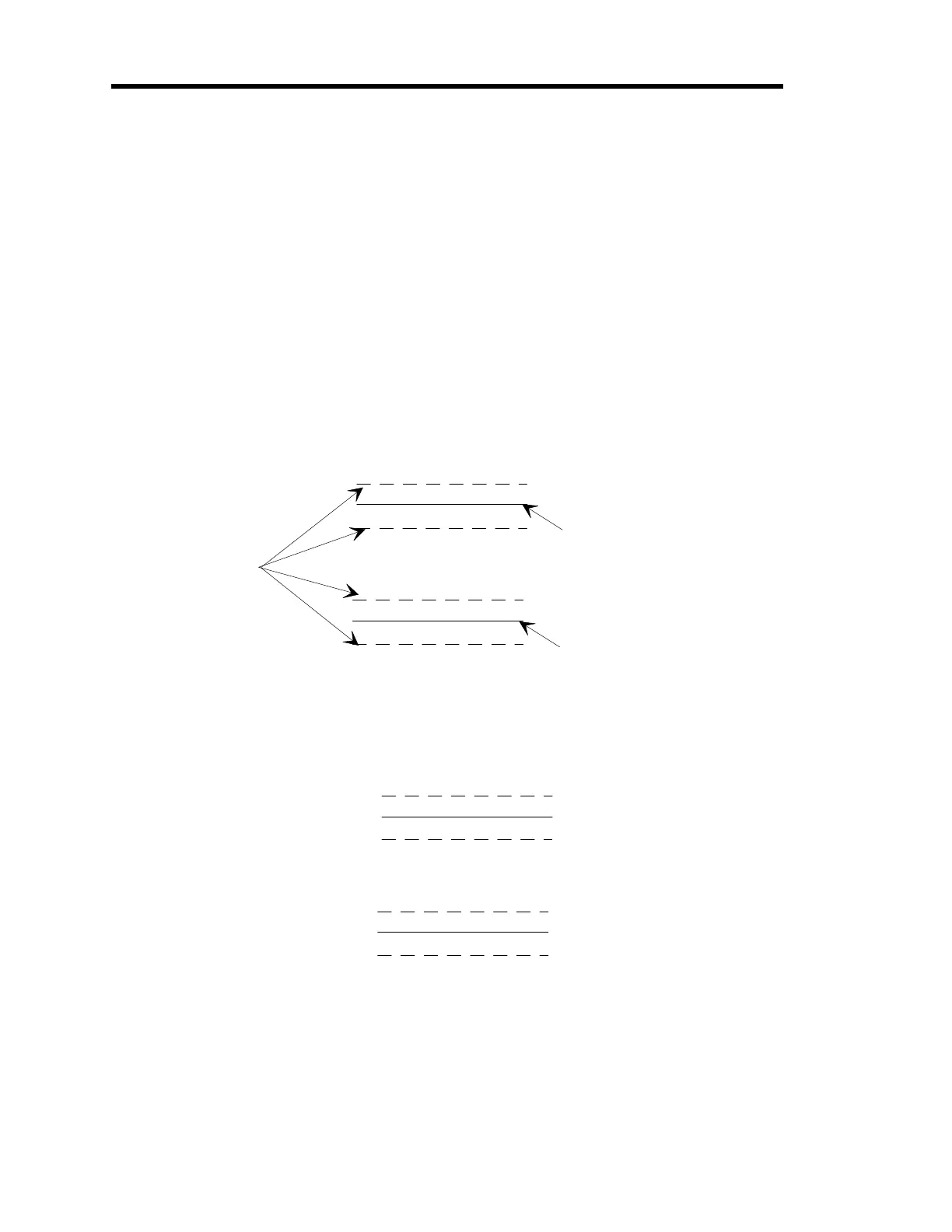

Example:

Setting the trip point high value to 100, the trip point low value to 50, and the

hysteresis entry to 1%, creates the hysteresis bands shown in Figure 13.

101

99

50.5

49.5

100

50

Figure 13: Hysteresis Bands and Trip Point Values

Therefore, the high trip point is activated when the pressure exceeds 101. It is deactivated when

the pressure drops below 99. The low trip point is activated when the pressure drops below 49.5.

It is deactivated when the pressure exceeds 50.5.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...