3 Installation

18

Series 275 Mini-Convectron Module with DeviceNet

Instruction Manual - 275563

• Do not install the Mini-Convectron where it will be subject to corrosive gases such as mercury

vapor or fluorine which will attack the gold plated sensor.

• Do not use the Mini-Convectron to measure pressures of explosive gases.

• For greatest accuracy and repeatability the Mini-Convectron should be located in a stable room

temperature environment.

• All connections to the unit are to be made with shielded cable or cables. The shield or shields

are to be connected to the connector shell.

3.3 Mini-Convectron Module Installation

Before installing the Mini-Convectron Module, install appropriate pressure relief devices in the

vacuum system. Granville-Phillips does not supply pressure relief valves or rupture disks. Suppliers

of pressure relief valves and rupture disks can be located via an internet search or the Thomas

Register under “Valves, Relief” and “Discs, Rupture."

Dimensions of the Mini-Convectron Module are given in Figure 2-2 on page 15.

Cleanliness pays. Keep the port cover in place until moments before installation.

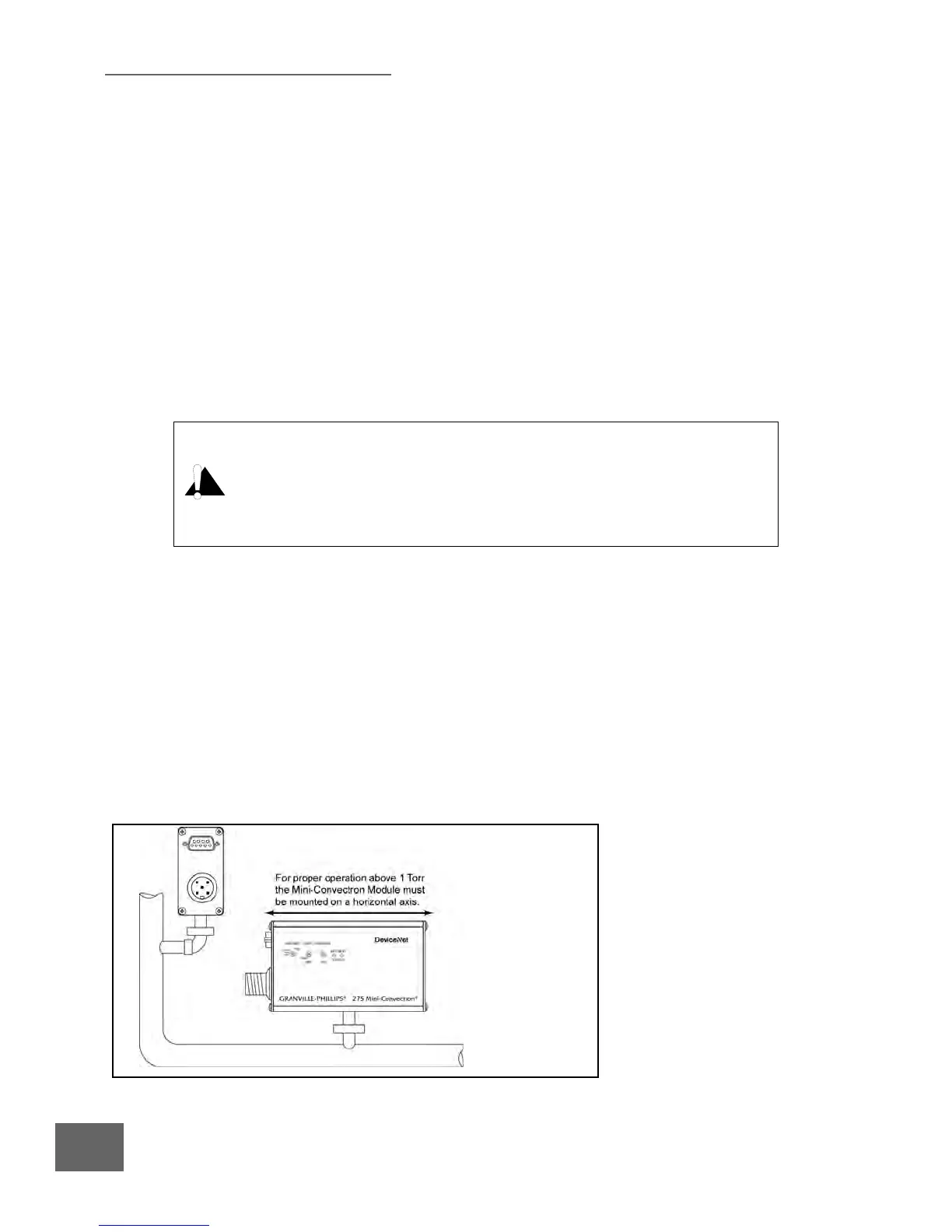

For proper operation above about 1 Torr, install Mini-Convectron Modules with the gauge axis

horizontal. See Figure 3-1. Although the gauge will read correctly below 1 Torr when mounted in

any position, erroneous readings will result at pressures above 1 Torr if the gauge axis is not

horizontal.

Orient the gauge to prevent condensation of process vapors on the internal surfaces through

line-of-sight access to its interior. If vapor condensation is likely, orient the port downward to help

liquids drain out of the gauge.

Vibration causes convection cooling of the sensor and will result in high pressure readings. Mount

Mini-Convectron Module where it will not vibrate excessively.

Operating the module above 1000 Torr (1333 mbar, 133 kPa) true

pressure could cause pressure measurement error or product failure.

Install suitable devices that will limit the pressure to the level that the

vacuum system can safely withstand. In addition, install suitable pressure

relief valves or rupture disks that will release pressure at a level

considerably below the pressure that the system can safely withstand.

Figure 3-1 Recommended Convectron Gauge Orientation

Loading...

Loading...