6 Service and Maintenance

59

Series 275 Mini-Convectron Module with DeviceNet

Instruction Manual - 275563

6.4 Troubleshooting and Repair

6.4.1 Symptoms and Possible Causes

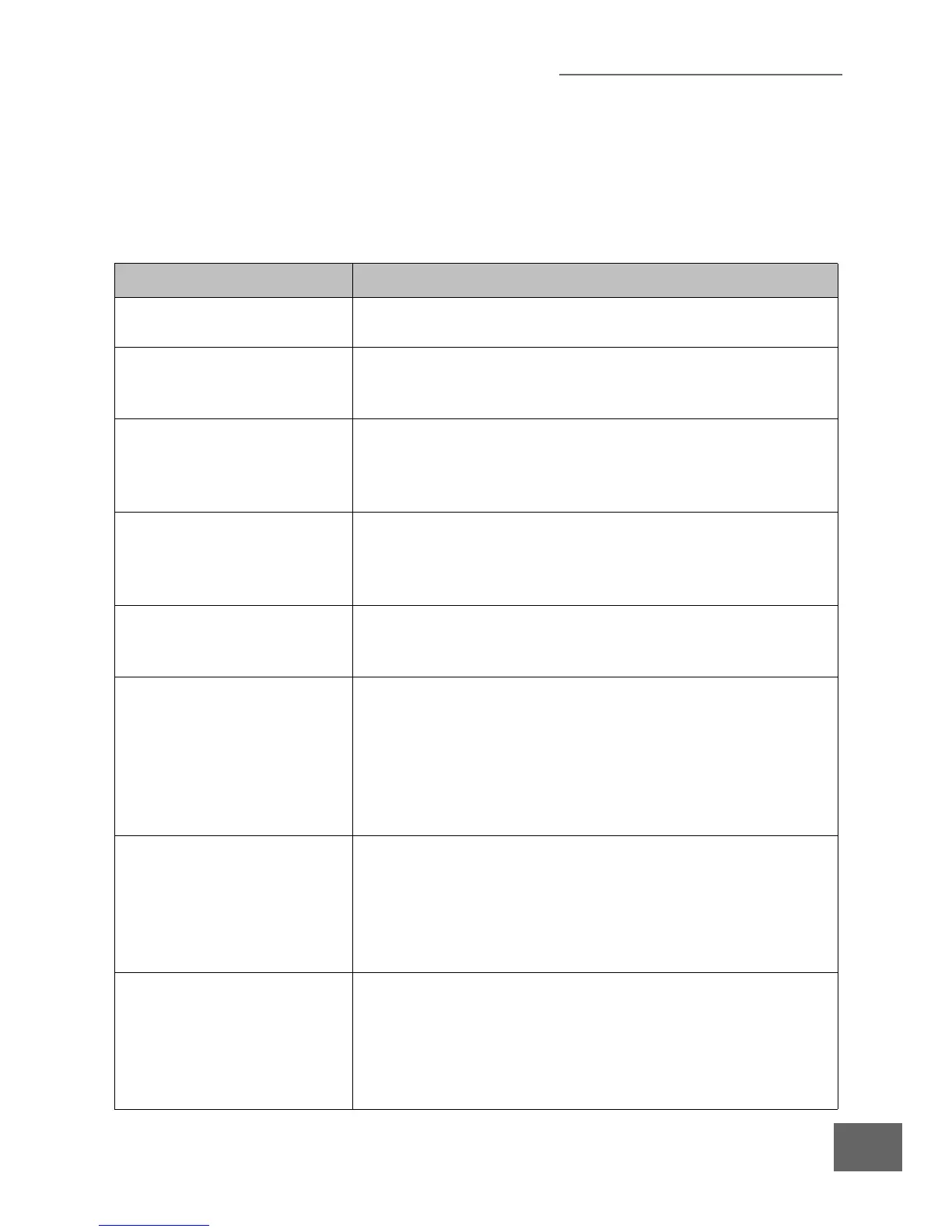

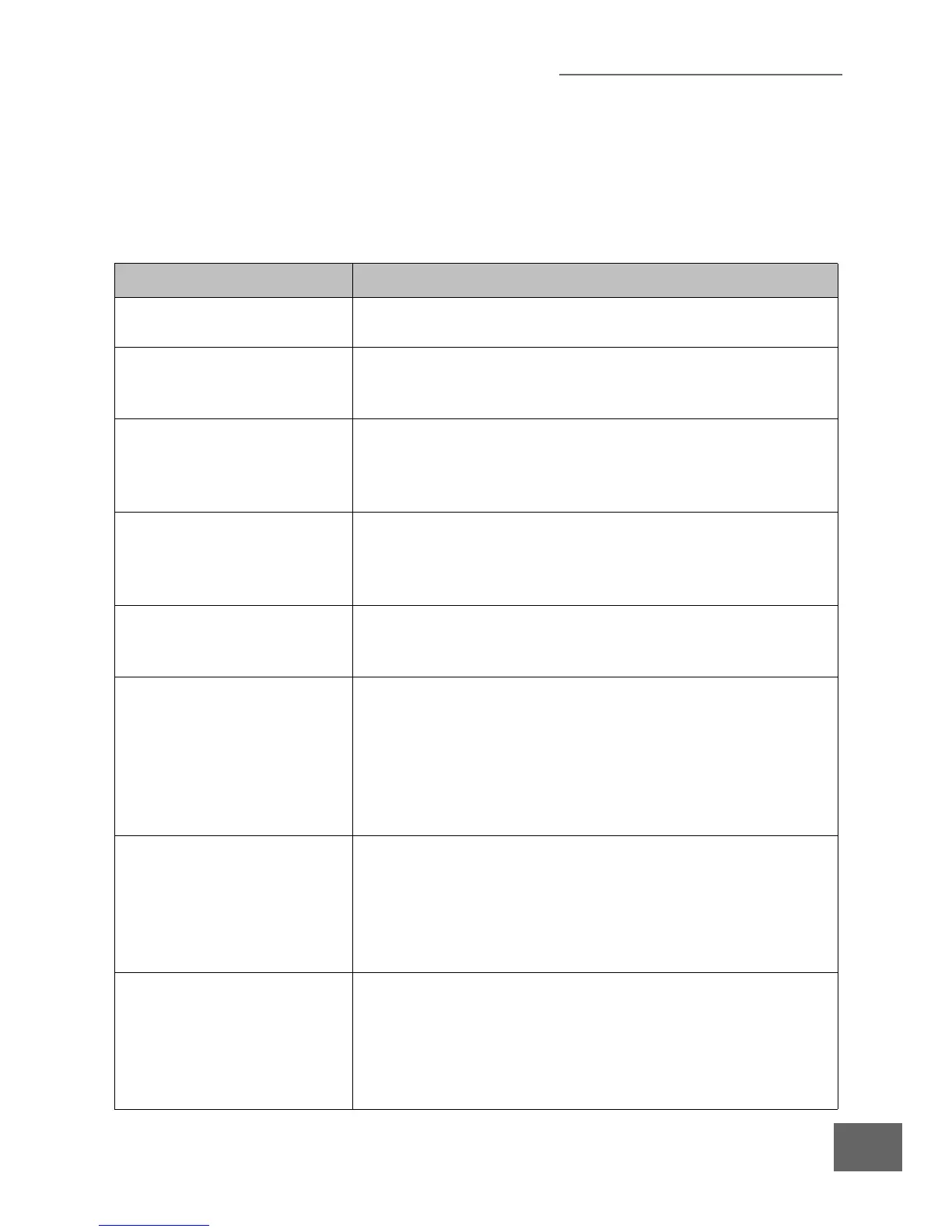

Table 6-1 General Symptoms/Possible Causes.

Symptom Possible Causes

The Mini-Convectron Module

will not power-up.

Check for +11 Vdc to +24 Vdc power across pins 2 and 3 of the

DeviceNet connector. See Section 3.4 in the Installation chapter.

The Bridge analog output

voltage reads less than +0.22

Vdc or greater than +10 Vdc.

Gauge tube failure. See Section 6.4.2 through Section 6.4.5 to check

the gauge tube.

Bridge amplifier failure. Replace the Module.

The Module does not respond to

DeviceNet communication from

a Master but the MOD Indicator

is illuminated solid green.

Address rotary switches set to incorrect address positions. Set the

address rotary switches to the correct address positions.

Incorrect baud rate. Set the baud rate switch in the correct position.

The MOD indicator does not

illuminate.

The DeviceNet power supply is disconnected, off, or inadequate for

the load. A switching supply may shut down from the current surge

upon power up. If a switching power supply is used, size the current

limit to two times working load.

The Module always reads

9.99e+09 via DeviceNet or the

MOD light turns red.

Fault condition indicated by reading response to status attribute. See

Section 5.1.5 for the DeviceNet command to check the status of the

Module, and to Section 5.4 for status bit definitions.

Pressure readout cannot be

calibrated using the specified

calibration commands.

The Convectron gauge tube is contaminated with material from the

vacuum chamber. Clean the gauge tube (see Section 6.4.5) or replace

the gauge tube.

If the gold plating on the sensor wire has been attacked by a gas such

as fluorine or mercury vapor, which has changed the emissivity or

resistance, cleaning the gauge tube will not solve the problem - the

gauge tube must be replaced.

The pressure readout from the

Mini-Convectron is vastly

different from that which is

observed by supporting gauges

on the vacuum system.

The gas composition in the vacuum chamber may not be what the

user believes it to be. Determine the actual type of gas in the chamber,

and calibrate the Mini-Convectron Module accordingly. See Section

3.6

in the Operation chapter.

U

nexpected gas sources can also be caused by the process within the

chamber or outgassing of the product in the process chamber.

Pressure reading grossly in error. The Module out of calibration.

Unknown gas type. Section 4.7.

The Module (gauge) is not mounted horizontally. See Section 3.3.

The Sensor is damaged (e.g., by reactive gas) or dirty. See Section

6.4.4 and Section 6.4.5.

Extremes of temperature or mechanical vibration.

Loading...

Loading...