6 Service and Maintenance

62

Series 275 Mini-Convectron Module with DeviceNet

Instruction Manual - 275563

6.4.5 Cleaning a Contaminated Convectron Gauge

The Convectron Gauge may be baked to 150 °C nonoperating while under vacuum with the

Module removed.

All materials are compatible for ultra high vacuum service, corrosion resistance, and bakeability.

The envelope is type 304 stainless steel. All metallic joints in the envelope are welded. No solder is

used within the envelope. The following materials are exposed to the vacuum: Type 304 stainless

steel, Carpenter Alloy 52, Kovar, Kapton, gold-plated Tungsten or Platinum (for the sensor),

borosilicate glass, and Dow-Corning 9015 glass. The blue trim cover is rated at 150 °C.

When the small sensor wire is contaminated with oil or other films, its emissivity or its diameter

may be appreciably altered and a change of calibration will result. Cleaning with trichloroethylene,

perchloroethylene, toluene, or acetone is possible but it must be done very carefully so as not to

damage the sensor.

1. Hold the gauge with the main body horizontal and the port projecting upward at an angle of

45 degrees. Slowly fill it with solvent using a standard wash bottle with the spout inserted in

the port to the point where it touches the screen. Let the solvent stand in the gauge for at least

ten minutes. Do not shake the gauge. Shaking the gauge with liquid inside can damage the

sensor wire. To drain the gauge, position it horizontally with the port facing downward.

Slightly warming the gauge will help dry the gauge.

2. Allow the gauge to dry overnight with the port vertically downward and uncapped. Before

re-installing the gauge on the system, be certain no solvent odor remains.

3. Install the gauge tube and reassemble the module.

4. Install the module onto the vacuum chamber and check it for proper operation.

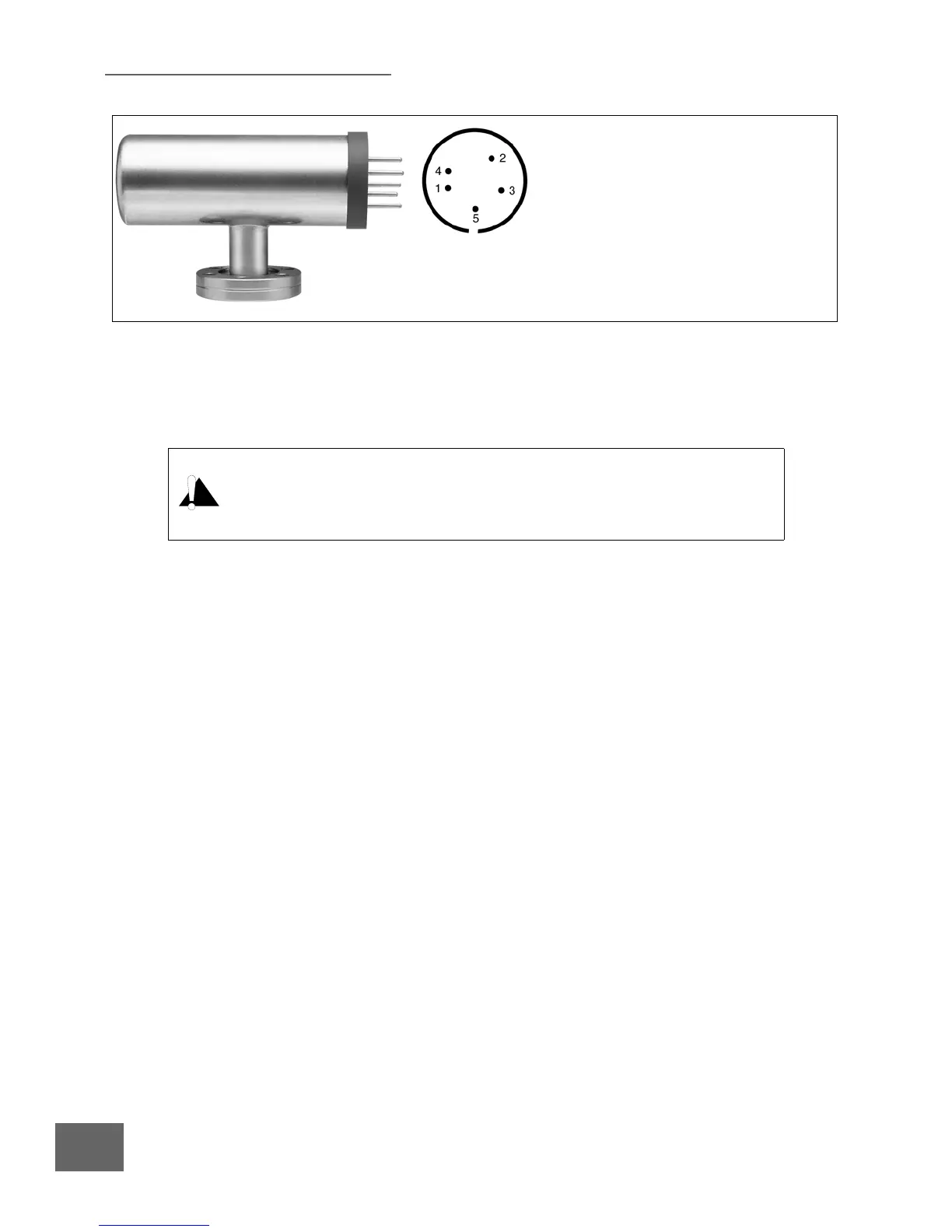

Figure 6-4 Convectron Gauge Connector and Resistance in Ohms

The fumes from solvents such as trichloroethylene, perchloroethylene,

toluene, and acetone can be dangerous to health if inhaled. Only use

these solvents in well ventilated areas exhausted to the outdoors. Acetone

and toluene are highly flammable and should not be used near an open

flame or energized electrical equipment.

• Pins 1 to 2: 19 to 22 ohms

• Pins 2 to 3: 50 to 60 ohms

• Pins 1 to 5: 180 to 185 ohms

If the resistance from pins 1 to 2 reads about 800 ohms,

the sensor wire in the gauge is broken. Replace the

gauge tube.

If the resistance values shown here are correct,

but you still think the gauge is not reading

correctly, the gold plating on the sensor wire

may be eroded and the gauge will have to be

replaced.

Loading...

Loading...