35

EN

TECHNICAL MANUAL - B CLASSIC / B FUTURA / S CLASSIC

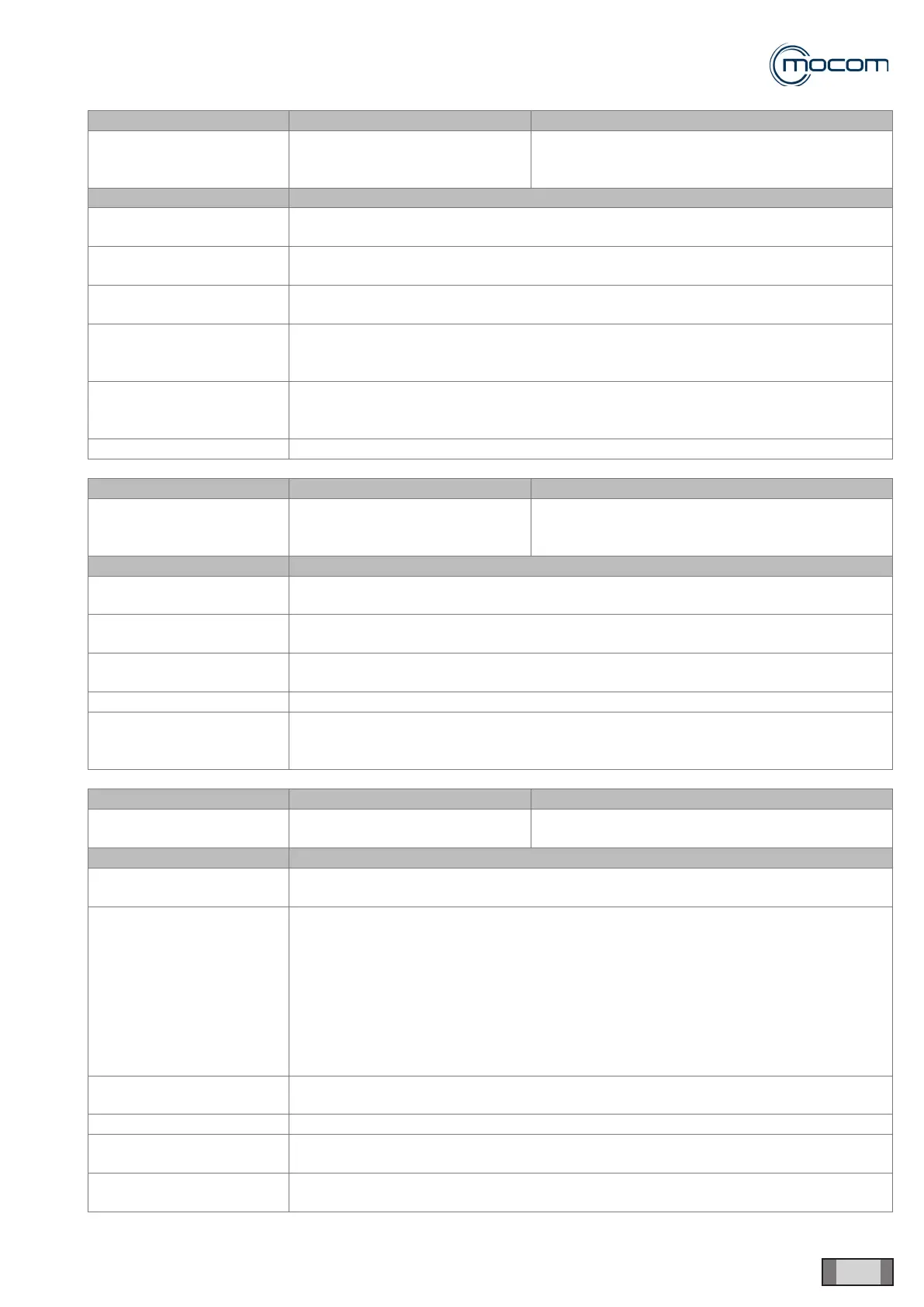

ALARMS

LCD H 400 Indication Alarm description Effect / Symptom

P/T PROBLEM

Pconv/T ratio not balanced

(Pconv greater than T) during

sterilization phase.

Difference between Pconv and

T is greater than 2°C.

Possible causes / Checks Solution

Drain solenoid valve EV1

does not open correctly.

Check cursor/cursor holder EV1 – see ST2 - MANIFOLD datasheet.

Firmware version not

updated.

Check/update autoclave FW version – see ST7-FW update.

Pressure transducer is

broken.

Change pressure transducer - see ST4-MPX_PRESSURE SWITCH datasheet.

PT1 – chamber

temperature detection fault.

Check proper storage of PT1.

Check by following SERVICE menu /PT1 CALIBRATION - SQ 26.

Change sensor PT1 – see ST5-PT1 datasheet.

Check for steam seepage

through door gasket.

Clean door gasket and steel ledge thoroughly.

Reset the alarm to repeat one sterilization cycle.

Change door seal.

Card is damaged. Change the electronic card.

LCD H 401 Indication Alarm description Effect / Symptom

T/P PROBLEM

T/Pconv ratio not balanced

(T greater than Pconv) during

sterilization phase.

Difference between T and

Pconv is greater than 2°C.

Possible causes / Checks Solution

Drain solenoid valve EV1

does not open correctly.

Check cursor/cursor holder EV1 – see ST2 - MANIFOLD datasheet.

Firmware version not

updated.

Check/update autoclave FW version – see ST7-FW update.

Pressure transducer is

broken.

Change pressure transducer - see ST4-MPX_PRESSURE SWITCH datasheet.

Card is damaged. Change the electronic card.

Check for steam seepage

through door gasket.

Clean door gasket and steel ledge thoroughly.

Reset the alarm to repeat one sterilization cycle.

Change door seal.

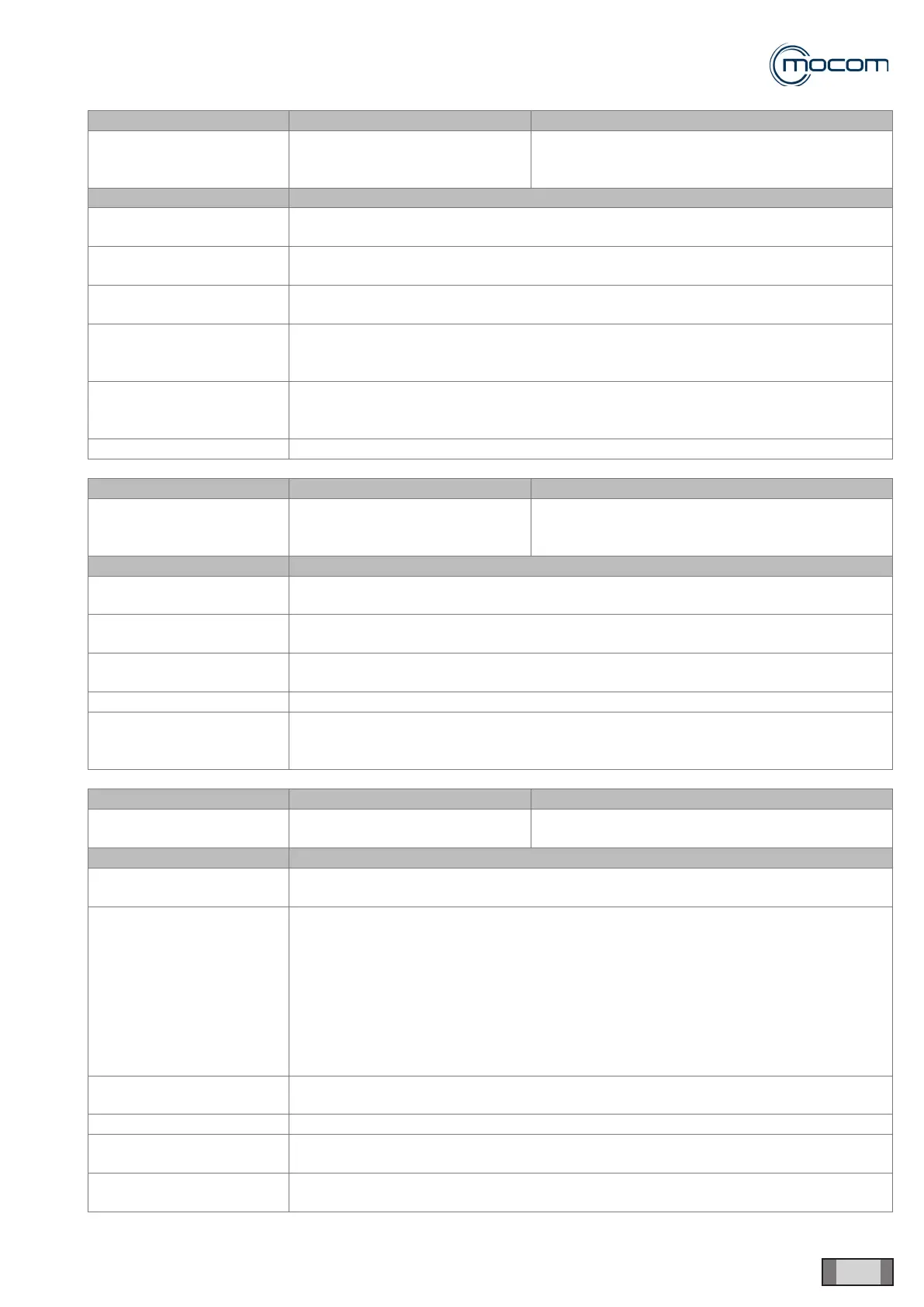

LCD H 402 Indication Alarm description Effect / Symptom

T ABOVE MAX LIMIT

Temperature above the MAX limit

during the sterilization phase.

Temperature reading of temperature sensor PT1 is

higher than Tnom + 4°C.

Possible causes / Checks Solution

Problem with steam

generator clogging.

Steam generator maintenance - See ST1-Steam generator datasheet.

Poor water feed to steam

generator.

The vibration pump of the

steam generator is not

operating properly.

Solenoid valve EV6 does

not open properly.

Check/clean feed tank lter.

Check/change vibration pump water lter.

Check vibration pump.

Check EV6.

To perform this check, it might be a good idea to activate vacuum pump and EV6 from

menu SERVICE/COMPONENT TEST/OTHER COMPONENTS – SQ 17, that lets you

detect water owing through the generator and into the chamber.

Change vibration pump.

Temperature sensor PT1 is

damaged.

Change PT1 – see ST5-PT1 datasheet.

Card is damaged. Change card.

Firmware version not

updated.

Check/update autoclave FW version – see ST7-FW update.

Check for air seepage

through door gasket.

Clean door gasket and steel ledge thoroughly.

Change door seal.

Loading...

Loading...