66

EN

B CLASSIC / B FUTURA / S CLASSIC - TECHNICAL MANUAL

SERVICE MENU

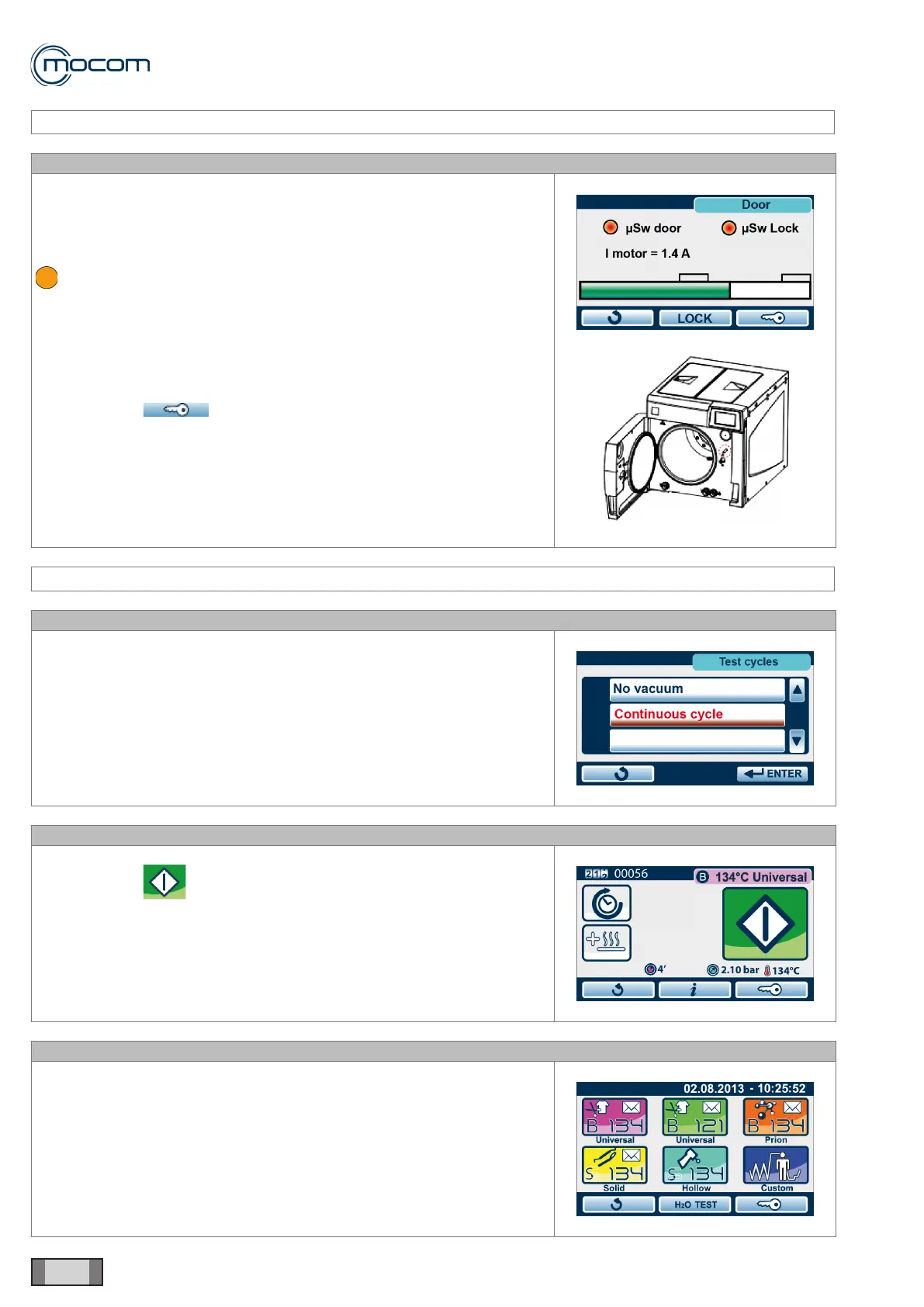

COMPONENT TEST – FUNCTIONAL CHECKS – DOOR

SQ20 - CHECK FOR DOOR MICROSWITCH ACTIVATION

Manually press the operating pin of the manual door closing microswitch,

and conrm that the μSw door indicator is activated.

Close the door and conrm that μSw door and μSw lock indicators are

activated.

microswitch closed/enable active.

After closing, the I motor indicator should read 1.4/1.8 A.

Activate door lock with LOCK command.

After locking, the I motor indicator should read 3.4/3.8 A.

With the LOCK command, you can unlock the door and bring it into closed

position.

With command , you can open the door and release both

microswitches.

With the door open, μSw door and μSw lock must be de-activated and

indicator I motor = 0.5 A.

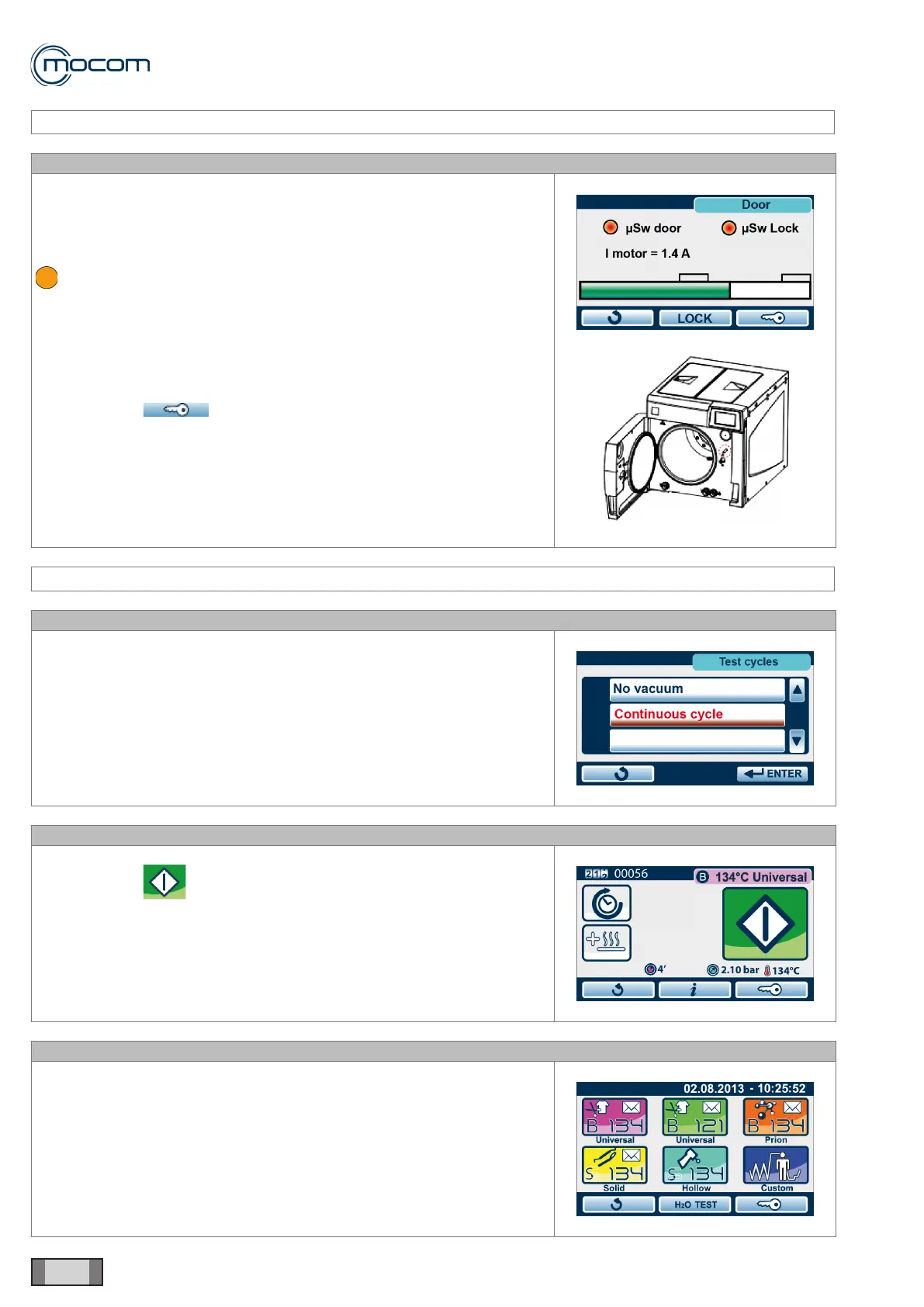

SERVICE MENU – TEST CYCLES

SQ21

Selecting TEST CYCLES displays a vertical scroll menu with the following

options:

- No vacuum

- Continuous cycle

SQ22

Selecting NO VACUUM displays the start-up screen for cycle S 134°C.

With command , you can activate the cycle, which will be performed

without the pre-vacuum phase.

After the warm-up phase, the pressure rise is performed to achieve the

process values of 134°/2.10bar, a condition that will be maintained for 4’.

This special cycle, which has no alarms, is designed to detect any steam

leaks from chamber, door, generator and connected tubes.

SQ23

Selecting CONTINUOUS CYCLE displays the cycle selection screen.

When one of the available cycles is selected and activated, that cycles

will run and repeated automatically with a 5’ pause between subsequent

cycles.

Loading...

Loading...