Do you have a question about the MTU 12V2000Gx6 series and is the answer not in the manual?

Lists the diesel engine models covered by this manual.

General safety information and warnings applicable to all products.

Defines the intended use and operational requirements for the product.

Outlines requirements for personnel qualifications and organizational measures.

Safety regulations for initial start-up and during engine operation.

Safety regulations to be followed during assembly, maintenance, and repair.

Safety measures for fire prevention, environmental protection, and fluid handling.

Explains the meaning of warning symbols and highlighted information.

Lists special tools, materials, and spare parts required for transport.

Explains the engine side and cylinder nomenclature used in the manual.

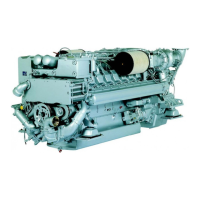

Provides a general overview of the engine and its main components.

Identifies key sensors and actuators on the engine.

Technical specifications for 12V/16V2000Gx6S engines in 3B application.

Technical specifications for 12V/16V2000Gx6S engines in 3D application.

Technical specifications for 12V/16V2000Gx6S engines in 3F application.

Technical specifications for 12V/16V2000Gx6S engines in 3G application.

Technical specifications for 12V/16V2000Gx6S engines in 3H application.

Technical specifications for 3B application with EPA Nonroad T2 certification.

Technical specifications for 3D application with EPA Nonroad T2 certification.

Technical specifications for 3F application with EPA Nonroad T2 and Stationary EMERG T2.

Technical specifications for 3G application with EPA Nonroad T2 certification.

Technical specifications for 3H application with EPA Nonroad T2 and Stationary EMERG T2.

Lists the firing order for different engine cylinder configurations.

Provides physical dimensions of the engine for different configurations.

Procedures for restarting an engine after long-term storage (>3 months).

Step-by-step guide for starting the engine, including safety warnings.

Steps for safely restarting the engine after an automatic shutdown event.

Routine checks to ensure proper engine operation and identify potential issues.

Safe procedures for shutting down the engine, including cooling down.

Steps for executing an emergency engine shutdown and post-shutdown actions.

Post-engine stop procedures, including coolant and system checks.

Instructions for cleaning the plant using high-pressure cleaners and compressed air.

Table detailing maintenance tasks and intervals for Non-EPA regions.

Table detailing maintenance tasks and intervals for EPA regions.

Diagnoses and actions for engine start problems.

Lists ECU9 fault codes, engine responses, and corrective actions.

Diagnoses for lube oil pressure and coolant level faults.

Diagnoses for fuel pressure and rail leakage issues.

Diagnoses for engine speed and starter problems.

Diagnoses for camshaft, crankshaft, and fuel pressure sensor faults.

Troubleshooting specific cylinder wiring faults (A1-A8).

Steps for performing an engine test run, including safety precautions.

Instructions for manually barring the engine using a barring tool.

Instructions and terms for examining cylinder liners.

Detailed steps for performing an endoscopic examination of cylinder liners.

Procedure for replacing the oil mist separator in the crankcase breather.

Steps to check the condition of the fan drive belt.

Procedures for checking drive belt tension using frequency meters and preload gauges.

Steps to adjust the drive belt tension.

Procedure for replacing the fan drive belt.

Procedure for checking and adjusting valve clearance.

Procedures for removing and installing the cylinder head cover.

General guidance on replacing the injector.

Detailed procedures and safety warnings for injector removal and installation.

Procedures for resetting drift correction parameters and entering injector coding.

Procedure for replacing HP fuel lines and pressure pipe necks.

Steps for venting the fuel system.

Instructions for draining fuel from the system.

Procedure for checking the fuel cooler for external contamination and leaks.

Instructions for cleaning the fuel cooler using compressed air or high-pressure cleaners.

Procedure for replacing the main fuel filter.

Instructions for draining fuel prefilters (non-switchable and switchable).

Procedure for replacing the filter element in non-switchable fuel prefilters.

Procedure for replacing filter elements in switchable fuel prefilters (Low Pressure Version A).

How to check the low pressure indicator on switchable fuel prefilters.

Procedure for checking fuel prefilter pressure ratios.

Steps for venting fuel prefilters (Low Pressure Version A).

Steps for replacing air filters and resetting the contamination indicator.

Procedures for removing and installing air filters.

Diagram and parts list for the electric starter.

Steps for safely removing the electric starter.

Steps for installing and electrically connecting the electric starter.

Diagram and parts list for the pneumatic starter.

Steps for safely removing the pneumatic starter.

Steps for installing and connecting the pneumatic starter.

Procedures for checking the engine oil level.

Steps for changing engine oil, with and without a semirotary hand pump.

Steps for replacing the engine oil filter.

Procedures for checking the engine coolant level.

Steps for changing the engine coolant.

Procedures for draining engine coolant.

Procedures for filling engine coolant.

Procedure for checking the relief bore of the engine coolant pump.

Procedure for extracting and analyzing engine coolant samples.

Procedures for filling charge-air coolant.

Procedures for draining charge-air coolant.

Steps for changing charge-air coolant.

Procedures for checking charge-air coolant levels.

Procedure for checking the relief bore of the charge-air coolant pump.

Procedure for checking the intercooler condensate drain.

Steps to check the condition of the drive belt for the battery-charging generator.

Procedures for checking drive belt tension on the battery-charging generator.

Steps to adjust the drive belt tension on the battery-charging generator.

Procedure for replacing the drive belt on the battery-charging generator.

Overview of overhaul procedures for preheater components like switches, elements, and thermostats.

Procedures for checking preheater function and for leaks.

Procedure for checking the heating element and housing for contamination.

Procedure for replacing the solenoid switch.

Procedure for replacing the safety thermostat.

Procedure for replacing the control thermostat.

Procedure for checking and tightening engine mounting screws.

Procedure for checking the condition of engine mounting resilient mounts.

Procedure for checking generator mounting resilient mounts.

Procedure for checking the firm seating of generator mounting securing screws.

Diagram showing the location of the Engine Control Unit and its connectors.

Procedures for removing and installing the Engine Control Unit.

Procedure for checking engine governor plug connections.

Procedure for checking engine cabling and electrical components.

Glossary of abbreviations used in the manual.

Information on contacting MTU for support, hotlines, and spare parts.

Lists special tools required for various engine maintenance tasks.

Lists special tools for barring and valve adjustment.