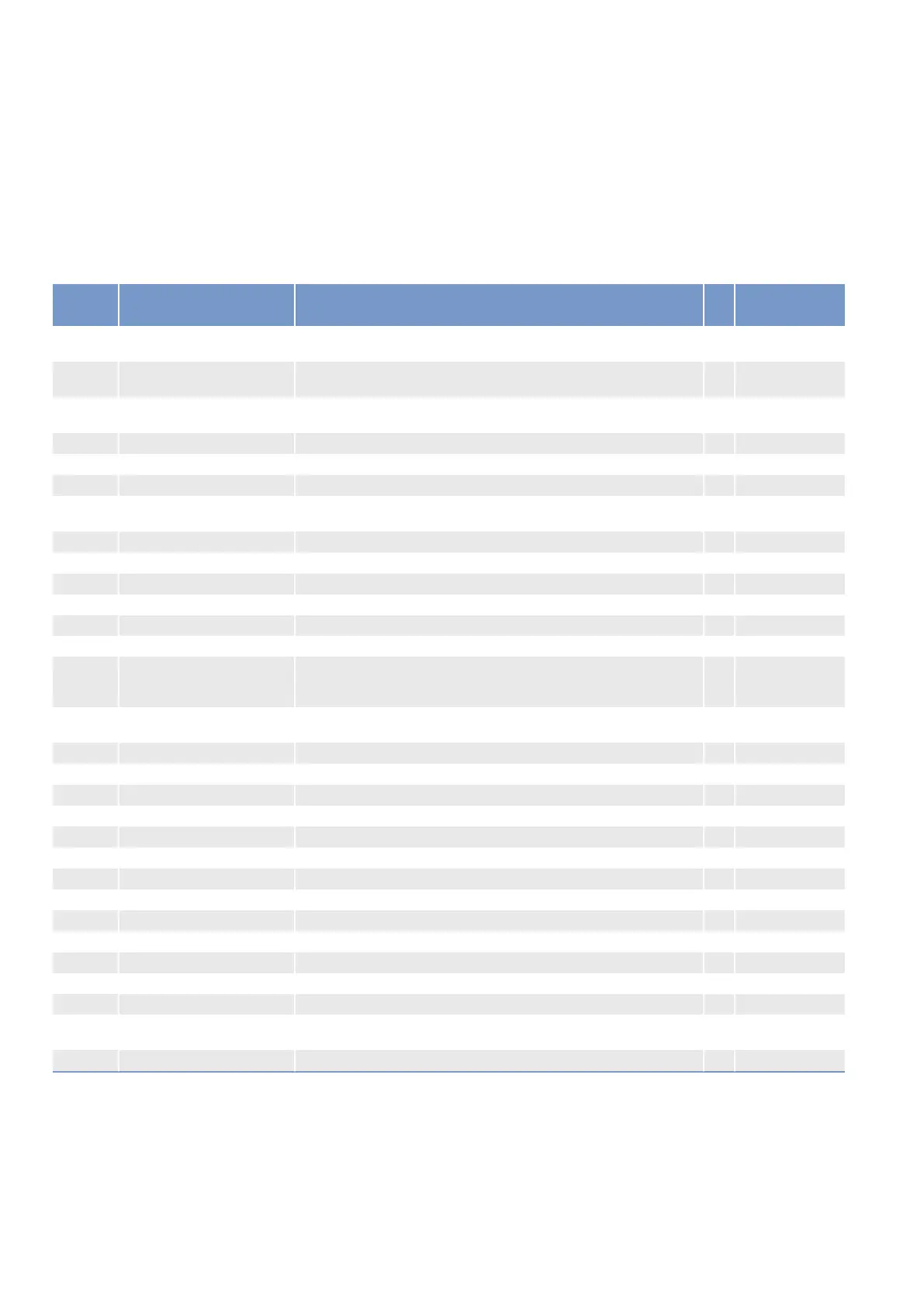

6.2 Maintenance task reference table [QL1] for EPA regions

The maintenance tasks and intervals for this product are defined in the Maintenance Schedule. The Mainte-

nance Schedule is a separate publication.

The task numbers in this table provide reference to the maintenance tasks specified in the Maintenance

Schedule.

Task Item Maintenance tasks

Option

WM00112 LABELS AND MISCELLANEOUS

MATERIALS

Check if emission label is present, check readability and content (→ Page 70)

WM00296 ENGINE GENERAL Carry out test run, minimum duration: until steady-state temperature is

reached, no less than 1/3 load (monthly)

X (→ Page 108)

WM00067 180, 183 Replace oil filter at each oil change or when the time limit (years) is reached, at

the latest

(→ Page 168)

WM00297 FUEL INJECTOR Replace rings (→ Page 127)

WM00172 HP FUEL LINE / HP LINE Replace HP fuel line (→ Page 133)

WM00289 ENGINE GENERAL Check engine for abnormal running noises, exhaust color and vibrations (→ Page 69)

WM00288 ENGINE GENERAL Check relief bore of coolant pump (→ Page 174)

(→ Page 181)

WM00287 ENGINE GENERAL Check maintenance indicator on air filter (→ Page 159)

WM00286 ENGINE GENERAL Visually check engine for leaks and general condition (→ Page 69)

WM00285 ENGINE GENERAL Check engine oil level (→ Page 166)

WM00086 FUEL FILTER Replace easy-change fuel filter (→ Page 141)

WM00136 ENGINE MOUNTING Check securing screws for firm seating (→ Page 214)

WM00050 ENGINE MOUNTING Check general condition of rubber mount (visual inspection) (→ Page 215)

WM00094 041, 055 Check valve clearance, adjust as necessary. IMPORTANT! Initial setting after

1,000 operating hours and every overhaul of cylinder heads after 1,000 operat-

ing hours

(→ Page 121)

WM00170 BATTERY-CHARGING GENERA-

TOR

Check condition of belt and replace as required. Adjust belt tension X (→ Page 183)

(→ Page 186)

WM00076 AIR FILTER Replace air filter (→ Page 157)

WM00106 CRANKCASE BREATHER Replace oil separator (→ Page 115)

WM00110 CYLINDER LINER Perform endoscopic examination of cylinder liner (→ Page 113)

WM00090 FUEL INJECTOR Replace fuel injector (→ Page 126)

WM00154 FUEL INJECTOR Reset parameters of drift correction (CDC) and enter injector codes (IIG) (→ Page 132)

WM00186 HP FUEL LINE / HP LINE Replace pressure pipe neck in cylinder head (→ Page 133)

WM00189 ELECTRIC POWER SUPPLY Check general condition of rubber mount (visual inspection) X (→ Page 216)

WM00188 ELECTRIC POWER SUPPLY Check securing screws for firm seating X (→ Page 217)

WM00222 202, 360, 367 Check operation and inspect for leaks X (→ Page 189)

WM00148 202, 360, 367 Replace thermostat (electric) X (→ Page 205)

WM00040 202, 360, 367 Overhaul preheating unit X (→ Page 188)

WM00215 360, 364 Drain water and contaminants from fuel prefilter X (→ Page 142)

WM00216 360, 364 Check reading on vacuum gauge X (→ Page 149)

WM00214 360, 364 Replace filter element X (→ Page 150)

(→ Page 152)

WM00228 360, 364 Check cooler elements for external contamination and leak-tightness X (→ Page 138)

Table 9: Maintenance task reference table [QL1]

76 | Maintenance | MS15054/03E 2018-07

TIM-ID: 0000080101 - 002

Loading...

Loading...