PAGE 20 — GENERATOR SERVICE AND TROUBLESHOOTING MANUAL — REV. #0 (08/29/23)

ELECTRICAL INSPECTION

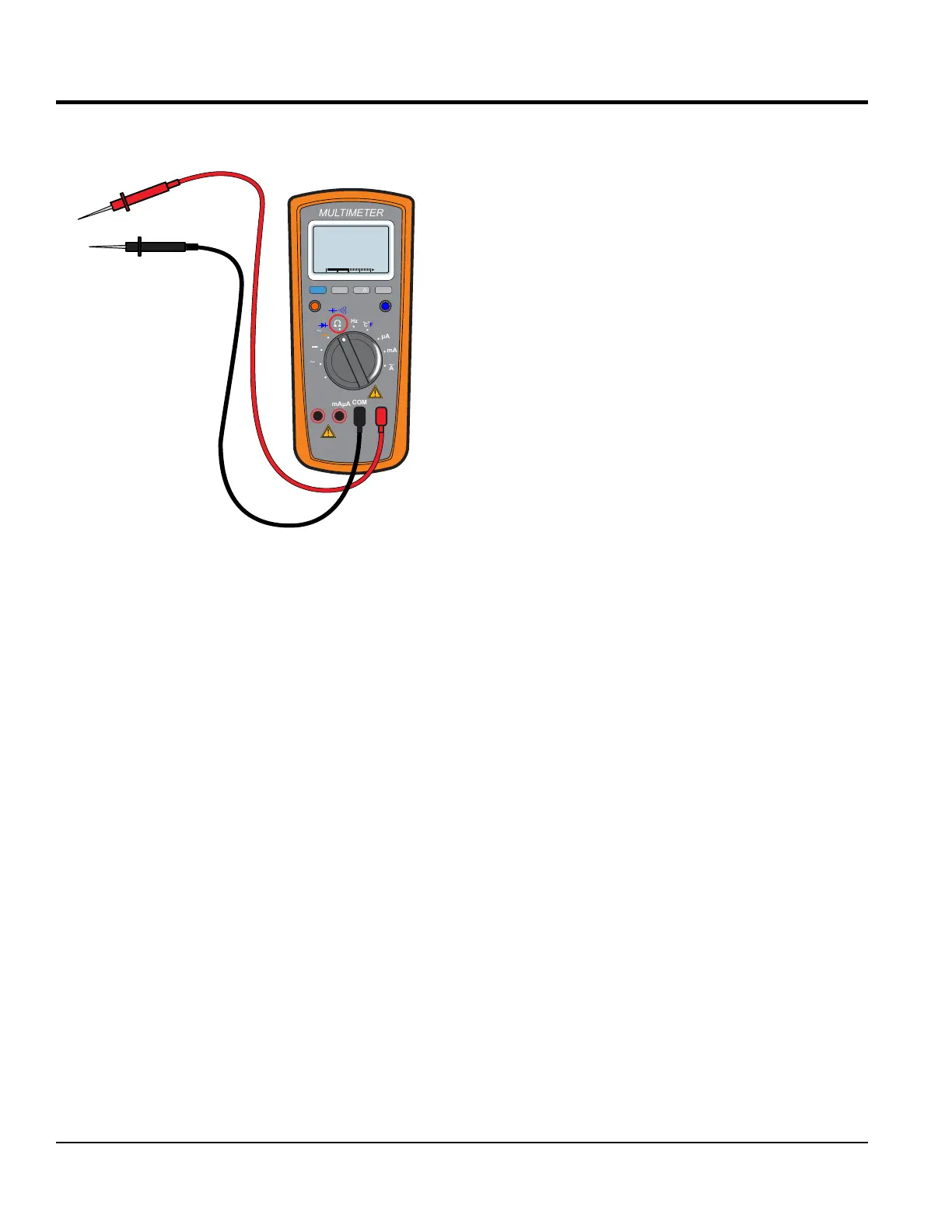

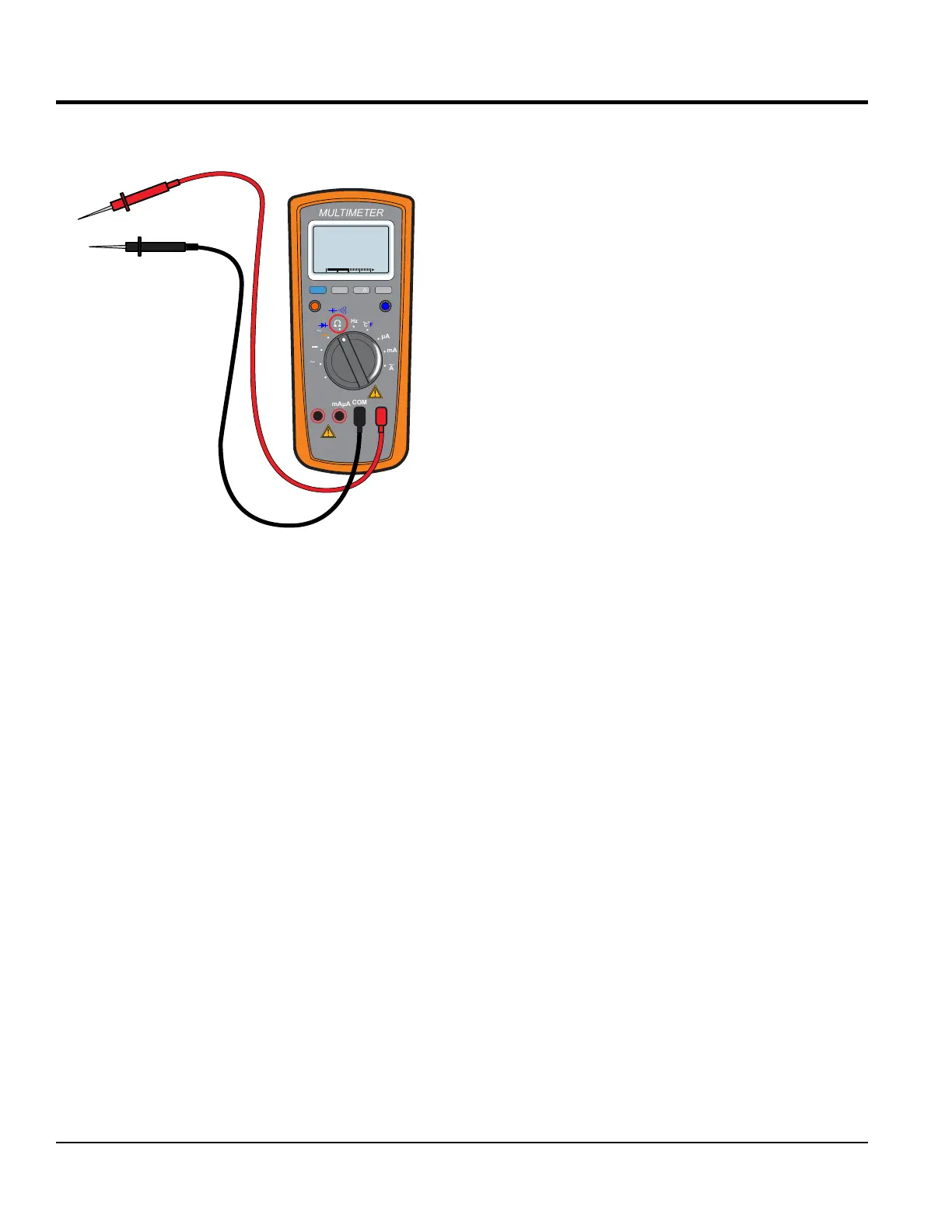

When servicing generators, having an accurate AC/DC

multimeter is a must (Figure 13).

Figure 13. AC/ DC Multimeter

ELECTRICAL INSPECTION

The rst step in generator troubleshooting is to conduct

a visual inspection before doing any electrical tests.

Looking over the generator carefully should expose any

environmental factors that might contribute to the problem.

As you remove the generator control box cover and begin

your inspection, look for the following:

Electrical Connections — Rusted, corroded and oxidized

connections will prevent the circuit from being completed.

This applies not only to the major cables externally, but

also to the electronic control devices internally.

Carbon Flash — If the AC receptacles on the generator

have ever been shorted, carbon ash deposits around the

120/240V AC receptacles may appear. This will indicate

whether the device that was plugged into the generator

shorted out the receptacle. The device may have shorted

the generator to ground and caused a carbon ash when

the plug prongs touched the receptacle.

Wire Overheating — Signs of wire overheating

(discoloration and a burnt smell) should be noticeable

inside the generator. Look to see if the windings turned

black. The winding insulative coating may vary in color from

shades of reddish brown to light brown to dark brown, so

try to compare the color to that of a new unit.

RANGE

MIN MAX

MULTIMETER

Auto0 600

OFF

Hz

C

A

mA

uA

F

V

Hz

V

mV

Hz %REL

HOLD/LIGHT

10 A

MAX

mAµA

COM

Infestation — Insects and rodents may have created a nest

inside the generator. These nests and associated debris

can cause electrical shorts. Generators left out in remote

areas provide a home for spiders, wasps other insects and

mice. Always inspect the generator daily.

Hardware — Loose hardware will shorten the life cycle

of the generator and decrease the overall performance of

the generator.

Terminal Lugs/Bus Bars — Always make sure all nuts,

bolts, screws, and fasteners are securely tightened.

DO NOT over tighten. Reference Torque Specications

(Table 9). Look for any elongation on the bolt hole opening

on the buss bar.

Electrical Connectors — Sometimes electrical connectors

do not always make a good connection. Always make

sure the electrical connectors are seated correctly. Some

electrical connectors may have more than a dozen

male-female connections.

These are often inside some plastic or rubber cover

that prevents you from seeing any possible corrosion.

In electrical troubleshooting, always unplug and plug

all connectors three times to produce a freshly scraped

metallic surface for good electrical contact.

Using an ohmmeter, check for zero ohms on all

connections. Spray the contacts with an electrical insulative

spray before reassembling them.

Crimp Connections — Even though they are widely used,

they can become loose as the machine vibrates and lose

consistent quality contact. Because dissimilar metals are in

contact, a galvanic cell is set up that may result in corrosion

when moisture is present.

Solder Joints — Solder joints that have cracked or broken

loose. This condition occurs much less frequently than

crimped connections and basically results from poor-quality

workmanship.

Wire Identication — Verify all unmarked wiring and

correct, particularly if the unit comes from another shop with

unresolved issues or you receive it partially disassembled.

Circuit Safety Devices — Check for physical damage to

housing, buttons and levers on all fuses, circuit breakers,

and ground fault interrupters.

Loading...

Loading...