GENERATOR SERVICE AND TROUBLESHOOTING MANUAL — REV. #0 (08/29/23) — PAGE 51

ECU 9988N

ENGINE CONTROL UNIT (ECU 9988N)

The ECU 9988N is an auto-start/stop engine controller.

This controller should not be confused with the actual

engine manufacturer’s Engine Control Module (ECM).

The ECM monitors engine operational inputs and directly

controls outputs for fuel delivery actuators, electronic fuel

injectors, etc. While the ECM does include safety

shutdowns, its main purpose is regulating fuel to meet

emission standards. The ECM is preprogrammed with

proprietary information by the engine manufacturer.

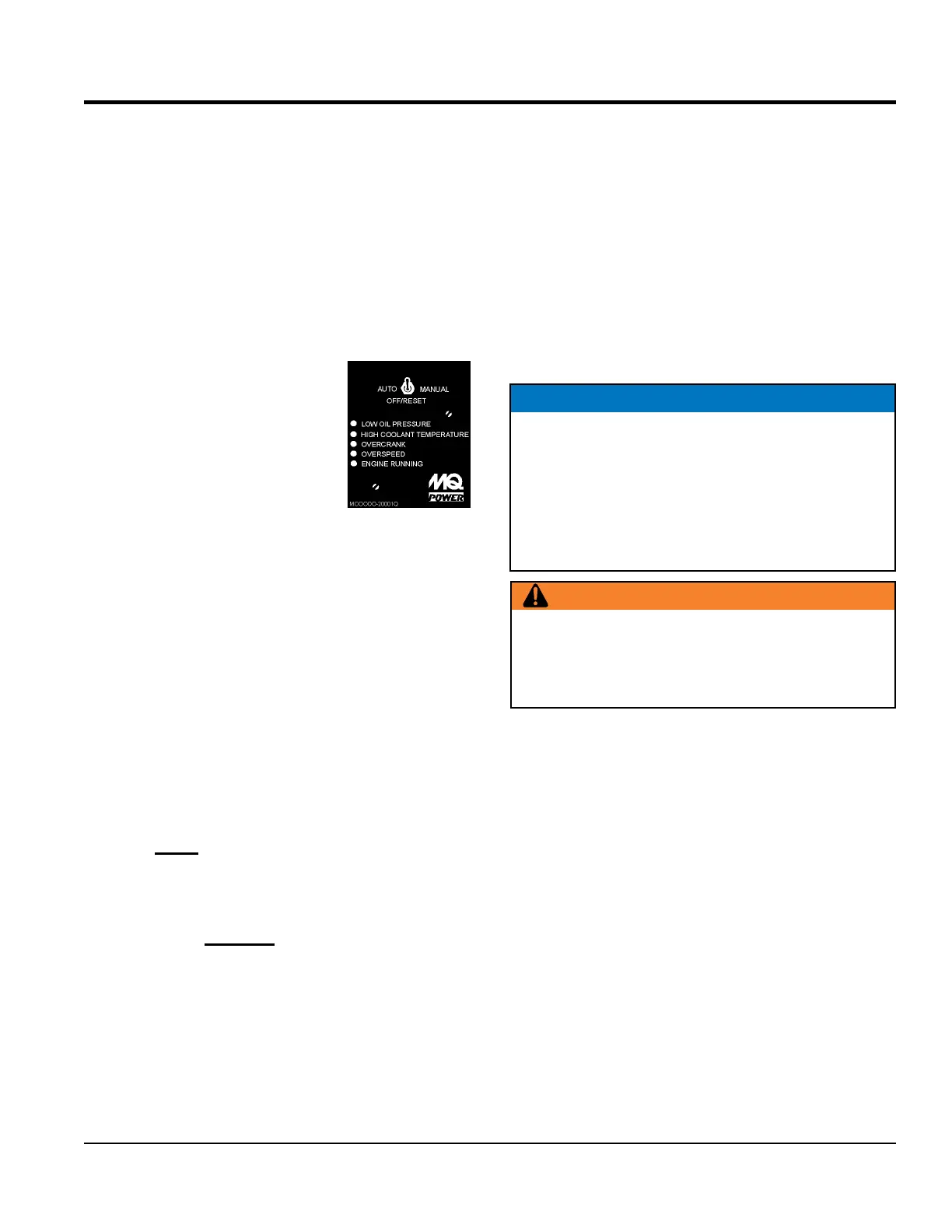

The ECU controller has a vertical row

of status LEDs (inset), that when lit,

indicate that an engine malfunction

(fault) has been detected. When a

fault has been detected, the engine

controller (ECM) will evaluate the fault

and all major faults will shut down the

generator.

During cranking cycle, the ECU will attempt to crank the

engine for 10 seconds before disengaging.

If the engine does not engage (start) by the third attempt,

the engine will be shut down by the engine controller’s

Over Crank Protection mode. If the engine engages at a

speed (RPM) that is not safe, the controller will shut down

the engine by initializing the Over Speed Protection mode.

Also the ECM will shut down the engine in the event of

low oil pressure, high coolant temperature and loss of

magnetic pickup. These conditions can be observed by

monitoring the LED status indicators on the front of the

ECU controller module.

Low Oil Pressure — Indicates the engine oil pressure

has fallen below a predetermined level. The oil pressure

is detected using variable resistive values from the oil

pressure sending unit. This is considered a major fault.

High Coolant Temperature — Indicates the engine

temperature has exceeded a predetermined level. The

engine temperature is detected using variable resistive

values from the temperature sending unit. This is

considered a major fault.

Overspeed Shutdown — Indicates the engine is running

at an unsafe speed. This is considered a major fault.

Overcrank — Indicates no engine start after 3 attempts

The ECU has a 3-position switch located at the top of

the unit. This switch controls the running of the unit. If this

switch is set to the OFF/RESET position, the unit will not

start. When this switch is set to the MANUAL position, the

generator will start immediately.

If the generator is to be connected to a building’s AC power

source via a transfer switch (isolation), place the switch

in the AUTO position. In this position, the generator will

monitor the AC line output from the building’s power source.

Once the building’s power drops below a specied level,

a signal will be sent to the generator via the auto-start

contacts and the the generator will start.

Figure 55 illustrates the ECU 9988N engine controller with

an energized-to-run engine. Placing the control switch in

manual position or closure of the remote start contacts

while in AUTO initiates the crank mode. The fuel and

starter relays are energized causing the engine to begin

cranking. If the engine does not start in the allotted time,

the overcrank fault occurs, and the fuel and starter relays

are turned off.

If during engine cranking the internal speed switch detects

a speed equal to or above the crank disconnect pre-set

value, the starter relay will turn off.

NOTICE

While operating in Auto mode, should a power outage

occur, the automatic transfer switch (ATS) will start the

generator automatically via the generator’s auto-start

contacts connected to the ATS’s start contacts.

Please refer to your ATS installation manual for further

instructions for the correct installation of the auto-start

contacts of the generator to the ATS.

WARNING

When running the generator in Auto mode, remember

that the generator can start up at any time without

warning. NEVER attempt to perform any maintenance

while the generator is in Auto mode.

Loading...

Loading...