GENERATOR SERVICE AND TROUBLESHOOTING MANUAL — REV. #0 (08/29/23) — PAGE 55

ECU 9988N

SINGLE OR MULTIPLE ENGINE CRANKS

(DIP SWITCH 4)

Using a small, at-blade screwdriver, set DIP switch 4

(Figure 56D) for either single or multiple engine cranks

as referenced in Table 4.

When DIP switch 4 is placed in the ON position (up) all the

multiple engine cranks will add together to create one large

engine crank. In effect it disables all other remaining cycles.

Placing DIP switch 4 in the OFF position will allow multiple

engine cranks as referenced in Table 3.

TESTING ENGINE OVERSPEED (DIP SWITCH 5)

After the engine has started and is running at normal speed,

using a small, at-blade screwdriver, place DIP switch 5 as

referenced in Figure 56D and Table 5 in the ON position

(up). If the overspeed potentiometer has been adjusted

correctly, the engine will shut down when an overspeed

fault occurs. For normal operation be sure DIP switch 5 is

placed in the OFF (down) position.

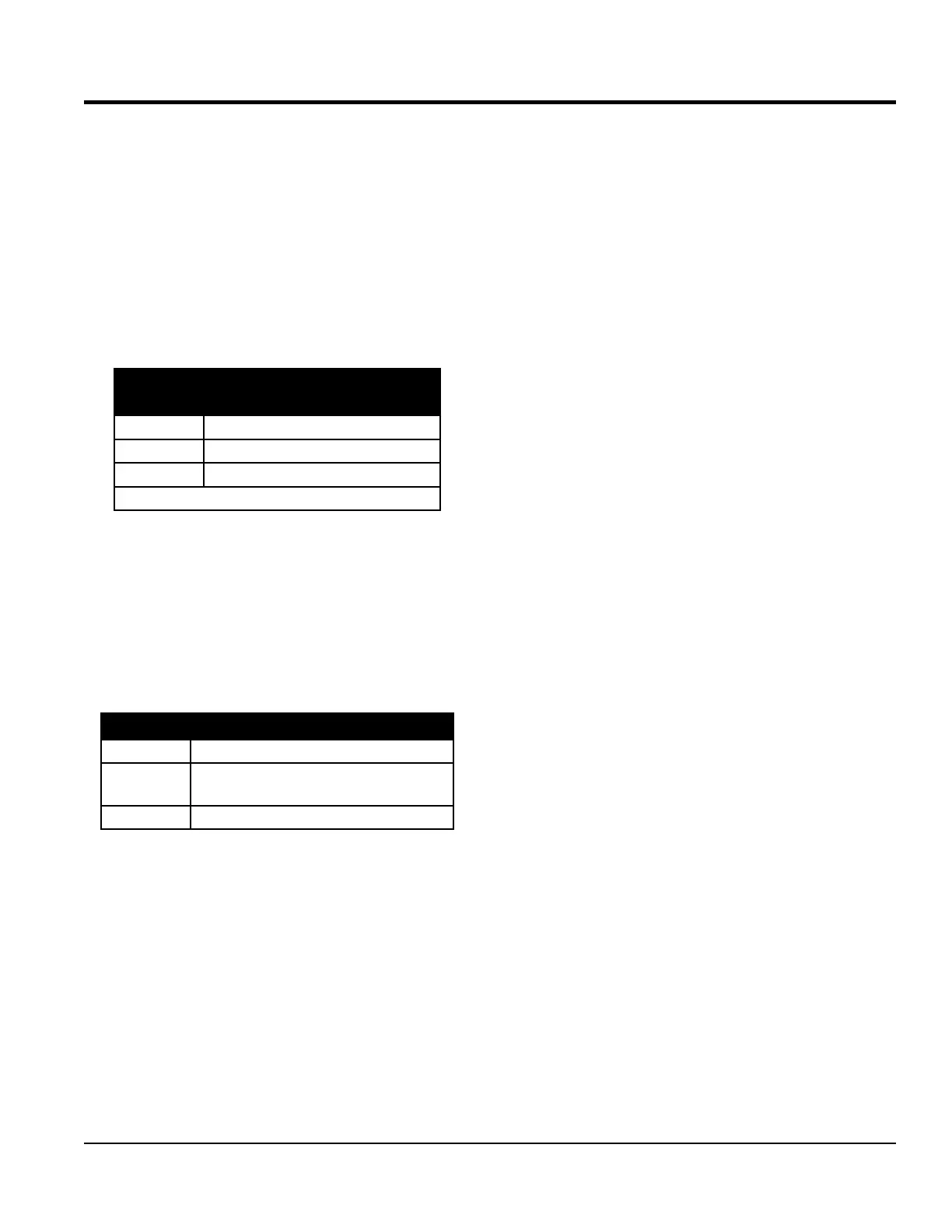

Table 4. Single/Multiple Engine Crank DIP

Switch Setting

SW4

1

FUNCTION

ON Single Engine Crank

OFF Multiple Engine Cranks

1

Factory built DCA units have Dip Switch 4 set to OFF.

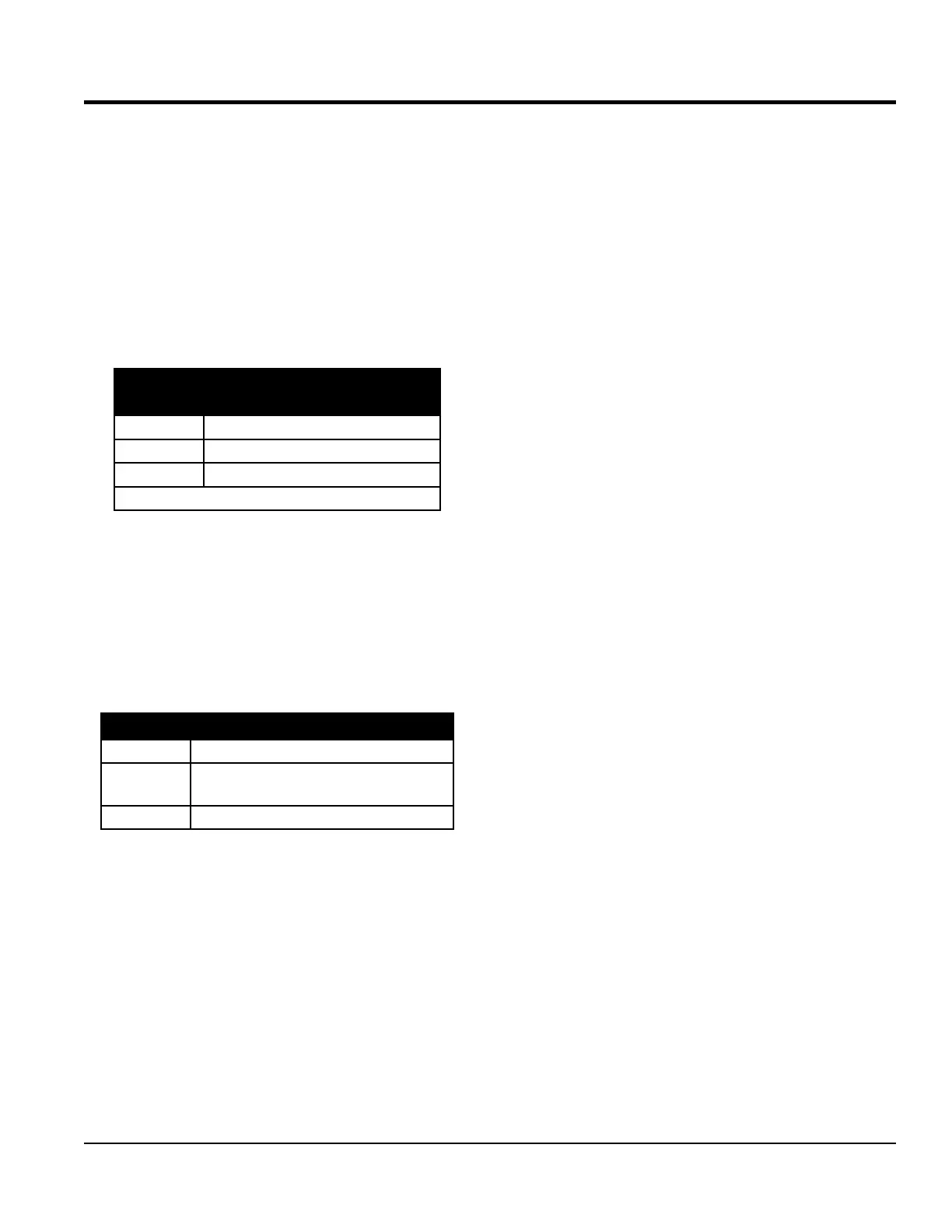

Table 5. Overspeed DIP Switch Setting

SW5 FUNCTION

ON

Makes ECU think engine is going approximately

13% faster than it really is.

OFF True engine speed (normal operation)

Loading...

Loading...