39 of 43

www.NabcoEntrances.com GT20 Wire and Programming Manual

Rev 5-7-18 P/N C-00140

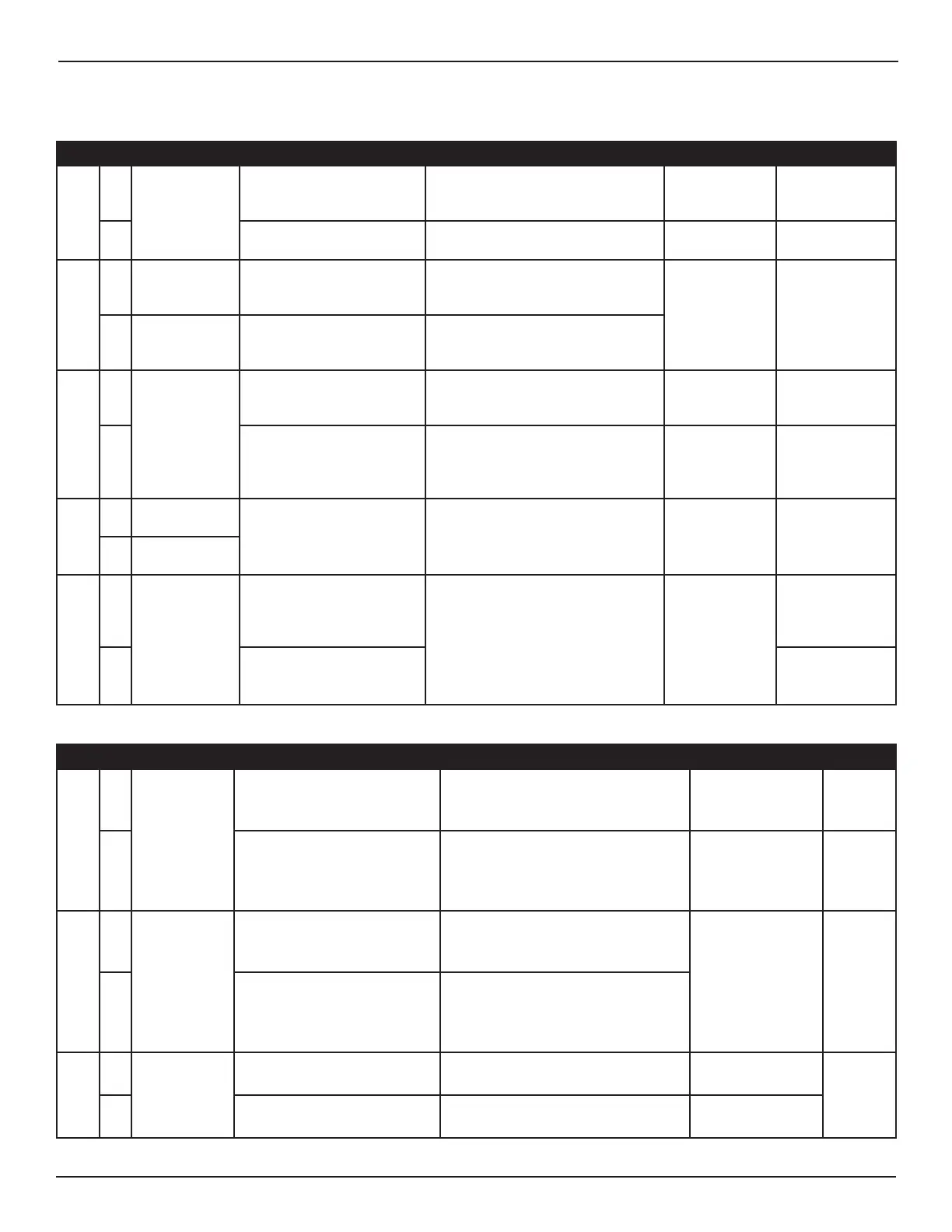

Table 21

No Description Cause Elimination Checking Time Reaction

E10 01 Fullteach

required

Parameter Ao, Rod, Invers

or dAxis changed

X Carry out a learn cycle Upon changing

the drive unit

conguraon

H

02 Minimum opening angle

has not been achieved

X Check the locking/electric lock During Teach H

E11 01 Haleach

required

(Opening)

Parameter Vo changed X Carry out a complete and

unhindered opening cycle

Upon changing

the speed

parameters

W

02 Haleach

required

(Closing)

Parameter Vc or FSlam

changed

X Carry out a complete and

unhindered closing cycle

E14 01 Locking/Elecric

Lock

The Door panel got caught

in the locking/electric lock

Check the funcon of the locking/

electric lock

When opening

from a closed

posion

H

02 The inverted operaon

has no locking, or the

interlocking force Fch has

not been programmed

Program/increase the interlocking

force Fch

At the end

of the teach

procedure

W

E15 01 Obstacle during

opening

Too many successive

obstacles have occured

X Examine the installaon

X Remove the obstacle

X Move the Door panel to the

target posion

Permanent H, A

Restart aer 60’s

02 Obstacle during

closing

E16 01 Temperature Temperature on output

level has reached 178° F

X Allow the unit to cool down Permanent A

Drive unit

funcons with

reduced power

02 Temperature on output

level has reached 196° F

A

Drive unit

has stopped

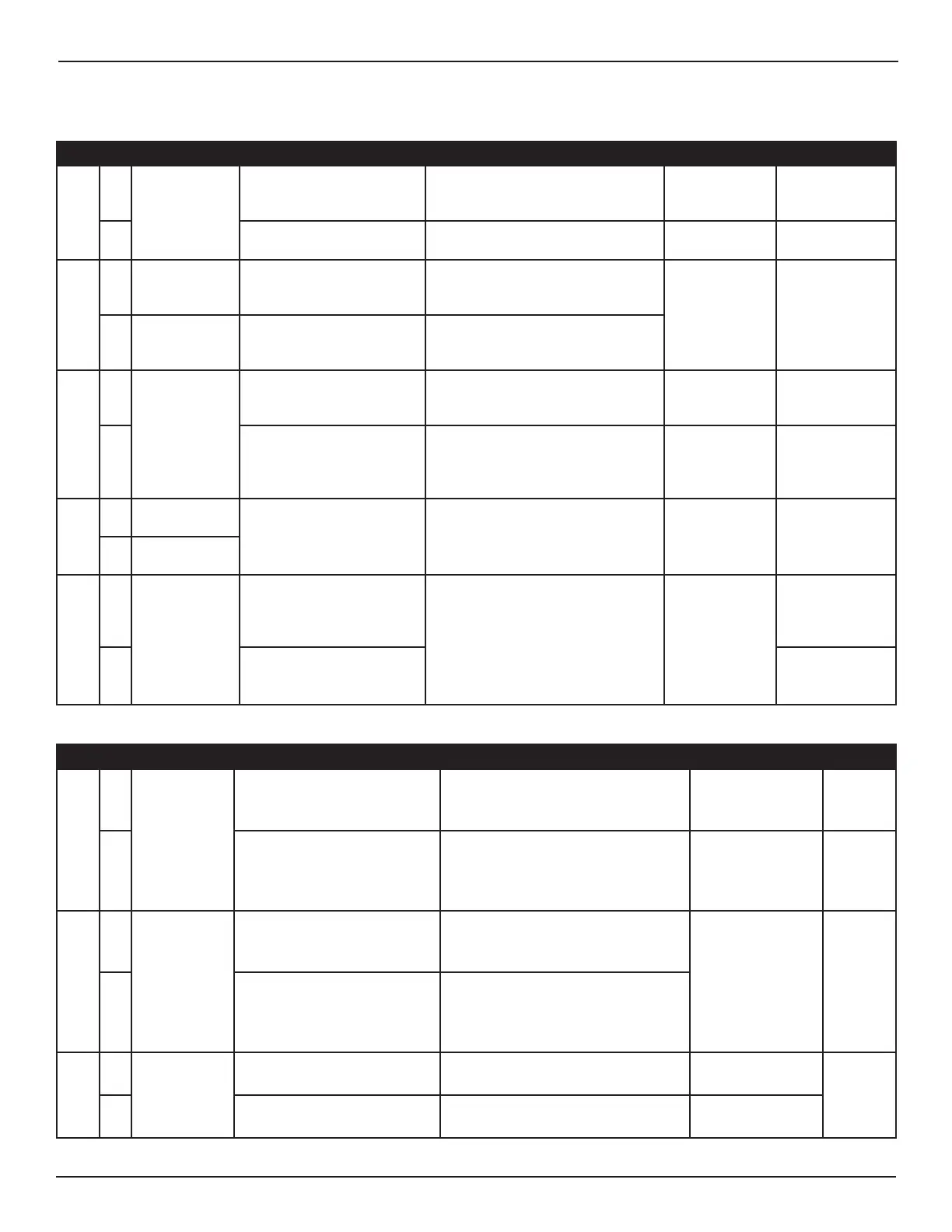

Table 22

No

Description Cause Elimination Checking Time Reaction

E20 01 SER Test SER Test signal unsuccessful SER short-circuit to the earth. Check

the cabling of the sensor or the

jumper

Prior to closing A

02 SER too slow SER reacts too slowly Check the

cabling of the sensor Check for

polarity reversal/test signal

E20-01 and

E20-02 together,

no line in between,

like E21

E21 01 SES Test SES Test signal unsuccessful SES short-circuit to the earth Check

the cabling of the sensor or the

jumper

Prior to opening A

02 SES too slow SES reacts too slowly Check the

cabling of the sensor Check for

polarity

reversal/test signal

E22 01 NOT Test NOT input on 24 V Check the jumpter NOT Check the

cablinf of NOT

Permanent H

02 Malfuncon Restart the control unit

SW Update necessary

Aer Power Up

Loading...

Loading...