© by NECTA VENDING SOLUTIONS SpA

8

07-2002 148 03

SANITISING THE FOODSTUFF

CIRCUITS AND THE MIXERS

When installing the unit, and then at least once a week or

even more frequently according to the use of the machine

and the quality of the inlet water, the mixers and the

dispensing conduits must be thoroughly sanitised (cleaned

and disinfected), to guarantee proper hygiene of the dis-

pensed products.

In order to make sanitising operations quicker, some

spare parts, which can replace the parts to be cleaned,

are supplied with the machine.

The parts to be cleaned are as follows:

- mixer and instant drink dispensing conduit;

- coffee dispensing spout;

- cup chute;

- dispensing compartment;

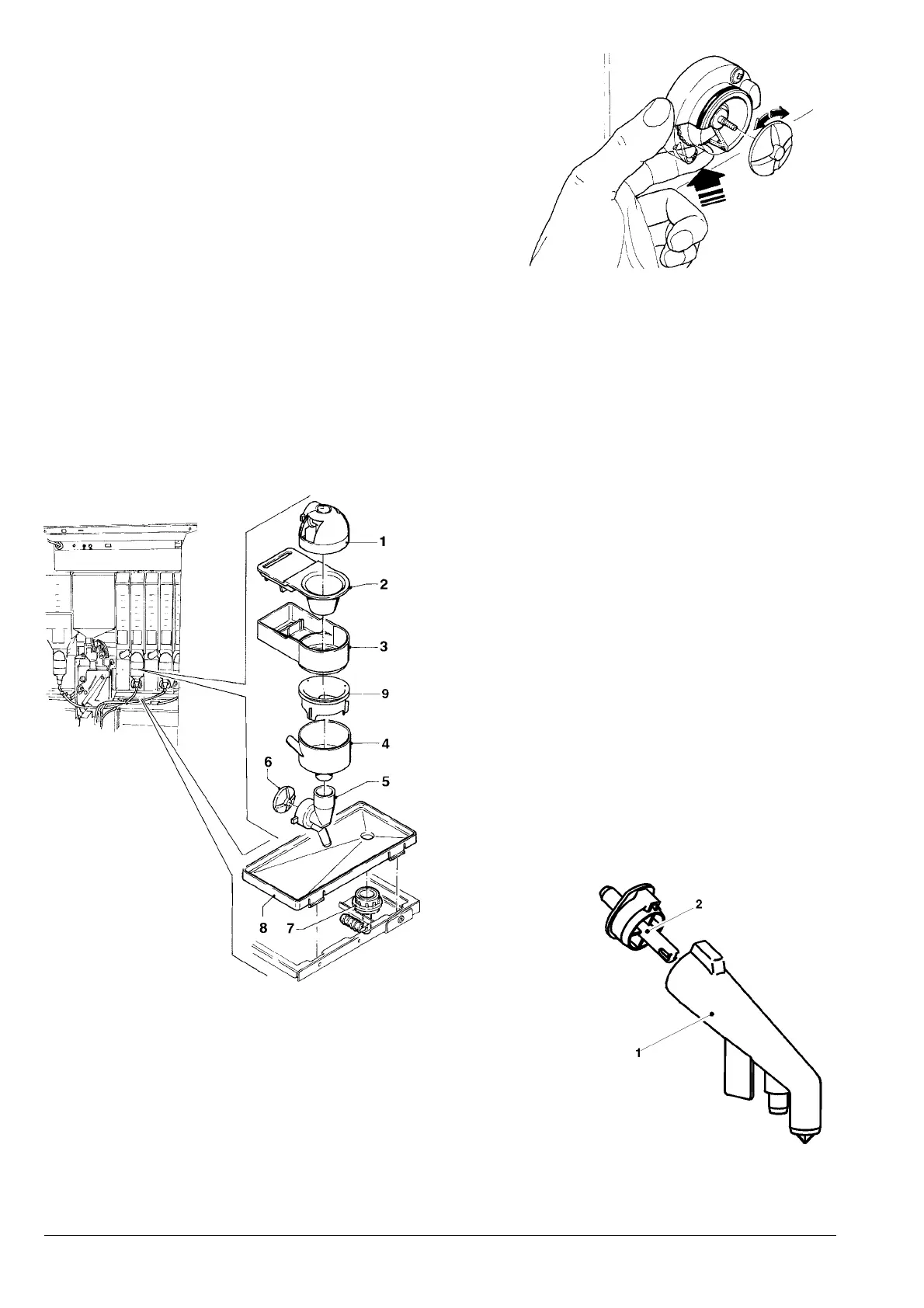

- remove the covers, the powder and the water funnels, the

feeders, the powder deposit drawers and the mixer wheels

from the mixers (see Figure 6);

Fig. 7

1 - Powder feeder

2 - Powder funnel

3 - Powder deposit drawer

4 - Water funnel

5 - Feeder

6 - Mixer wheel

7 - Tray drain

8 - Overflow tray

9 - Splash guard ring

Fig. 6

- a splash guard ring is also fitted in the fresh coffee and

milk mixers; this must be cleaned and then replaced in

the same mixers;

- in order to remove the wheels, block the disk fitted on the

mixer shaft with a finger (fig. 7);

- wash all parts with detergent being sure that all visible

residue and product layers are mechanically removed,

using a brush if necessary;

Disinfection should be carried out using chlorine-based

detergents;

- soak all components for approx. 20 minutes in a container

filled with the previously prepared chlorine-based deter-

gent;

- reinstall the feeders and the water funnels;

- reinstall the powder deposit drawers and the powder

funnels after thoroughly drying them.

After reinstalling all parts the following is however

required:

- enter into "Filler" mode to clean the mixers (see relevant

paragraph) and add a few drops of the chlorine-based

detergent in the various funnels

- After disinfection thoroughly rinse all components to

ensure that all residue of the detergent solution is re-

moved.

All operations requiring the machine to be energized

should be carried out by qualified personnel ONLY,

informed about the specific risks of such situation.

Some models, with the fresh product being dispensed

directly into the cup, are fitted with a special spout (see

fig. 8), as alternative to the splash guard ring, preventing

the pressure created by the brewer piston from being

discharged into the cup.

Fig. 8

1 - Tea dispensing spout

2 - Plug

Also this spout and its plug must be cleaned following the

same procedure indicated for the mixers.

Loading...

Loading...