13

© by NECTA VENDING SOLUTIONS SpA 07-2002 148 03

Brewing will continue for a preset period of time, which can

be programmed via software, then the piston is lowered

to dispense the brewed drink and dry the dose of grounds.

At the end of drink dispensing, the filter holder will be

lowered, the filter holder motor (15-5) moves back the

sliding filter holder, thus enabling the grounds to be

removed by the scraper (15-6).

It is also possible to program a pause for drying the product

dose to further improve the drink quality.

To improve the product aspect, a special dispensing spout

is used on some models (see Fig. 8), for the purpose of

preventing the pressure generated by the brewing piston

from being discharged directly into the cup.

CHECKING AND ADJUSTING THE MA-

CHINE SETTINGS

To get the best results from the product used, the following

should be checked:

- The dose weight of the instant products;

- The water dose;

- The drink temperature.

The weight of instant products and the water dose are

directly controlled by the microprocessor.

To adjust them it is therefore necessary to follow the

programming procedures.

STANDARD SETTINGS

The vending machine is supplied with the following set-

tings:

- Brew temperature (at the spout) approx. 85-89°C;

- Instant product temperature (at the spout) approx. 75°C.

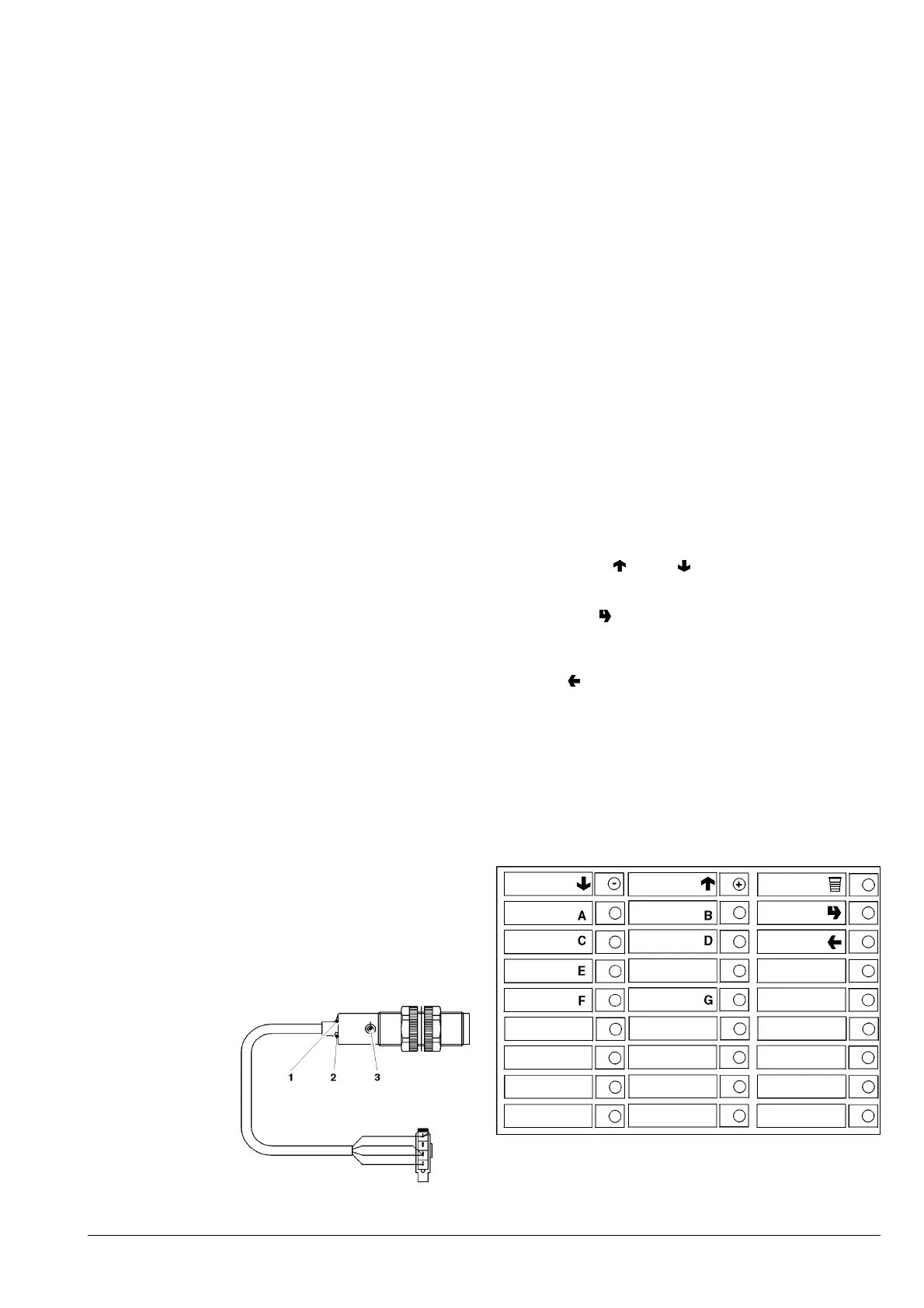

CUP SENSOR

The cup sensor (fig. 16) is adjusted in such as way as to

detect objects (red LED glowing) placed between the

sensor lens and the reflector.

The green LED glows when the reflector is read correctly.

By means of the trimmer (preset at the factory) the

sensing depth can be varied; the correct setting is

approximately 30°, clockwise, from the maximum.

For a correct operation, the infrared transmitter and the

reflector must be kept clean.

Fig. 16

1 - Green LED

2 - Red LED

3 - Adjustment trimmer

OPERATING MODES

Three different operating modes are provided for the

machine; the buttons will have different functions accord-

ing to the machine operating mode.

The available operating modes are as follows:

FUNCTIONS

Normal mode coins accepted

products dispensed

Filler menu test dispensing

machine maintenance

Technician menu programming

different parameters

USER INTERFACE

The interaction between system and user occurs through

the following components:

- Liquid crystal display (LCD) 4 lines of 20 characters.

- External push-button panel, with keys which have the

following functions when in “Filler” and “Technician”

mode (see Fig. 17):

Scrolling keys “

” and “ ” :

To move to the next or previous menu option.

Confirm key “

”:

To go from a menu to a sub-menu, or to confirm the

information on the display.

Exit key “

”:

To move back from a sub-menu to the higher level menu,

or used to cancel the current information on the display.

It is also used to go from “Filler” mode to “Technician”

mode and vice versa.

Fig. 17

Loading...

Loading...