27

© by NECTA VENDING SOLUTIONS SpA 07-2002 148 03

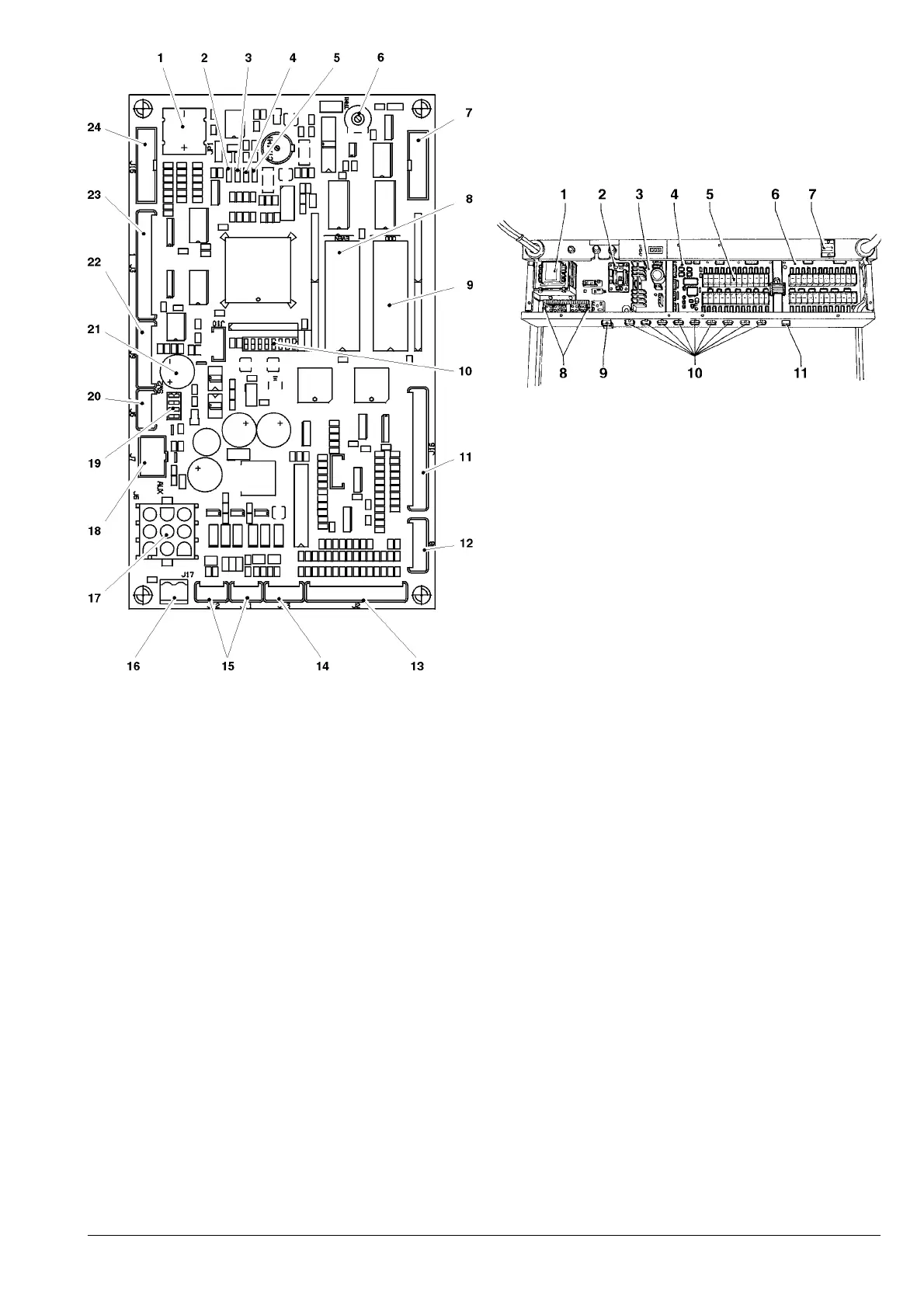

Fig. 20

1 - Battery

2 - Green LED: RUN

3 - Yellow LED: 5 Vdc

4 - Red LED: program error

5 - Red LED: board reset

6 - LCD contrast control trimmer

7 - LCD connector

8 - EPROM: EVEN

9 - EPROM: ODD

10 - Configuration Minidips

11 - Service keys connector

12 - Connector not used

13 - Key-pad connector

14 - Cold unit connector

15 - Connectors for control board communication

16 - 24 Vdc power supply to board

17 - BDV connector

18 - MDB connector

19 - Coin mechanism setting Minidip

20 - Connector not used

21 - Buzzer

22 - RS232 connector to programmer

23 - Connector of cup and sugar control board

BOILER CONTROL BOARD

This board controls the instant boiler heating element.

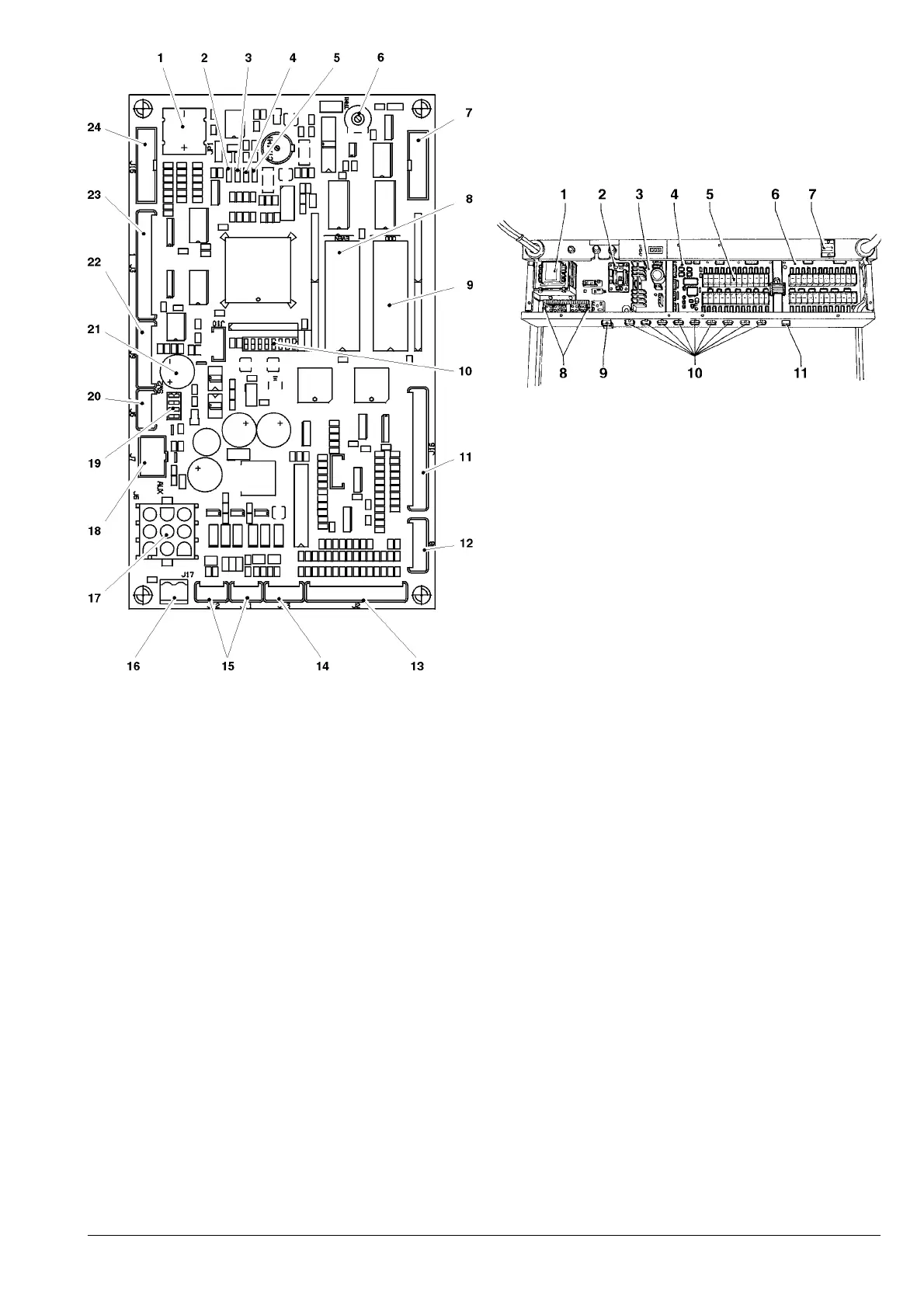

Fig. 21

1 - Transformer

2 - Boiler control board

3 - Power supply board

4 - Actuation board

5 - Relay

6 - Expansion board

7 - Mechanical counter

8 - Transformer primary/secondary winding fuses

9 - Instant boiler connector

10 - Solenoid valve connector

11 - Sanitising kit connector (optional)

ACTUATION BOARD

This board (see Fig. 22) activates, by means of relays,

some of the 230V~ components of the machine.

This board is powered with 24 VDC.

The control board EPROM is fitted on this board:

- green LED, blinking at intervals of approximately one

second, indicates that the microprocessor is working

correctly; if blinking fast it indicates that there is no

communication with the CPU card.

- red LED “H1”, indicates the operating status of heating

element on the first espresso boiler(if installed).

- red LED “H2”, indicates the operating status of heating

element on the second espresso boiler (if installed).

- red LED “H3”, indicates the operating status of heating

element on the instant boiler.

Loading...

Loading...