9

© by NECTA VENDING SOLUTIONS SpA 07-2002 148 03

WEEKLY CLEANING

OF THE BREWER UNIT

On a weekly basis, besides cleaning the external parts of

the brewer unit to remove any powder residue, especially

in the area of the funnel, also the parts of the unit which

come into contact with the drink should be sanitised.

These operations must be carried out with the power

switched off.

- Undo the fastening screw and remove the cover to

access the brewer unit.

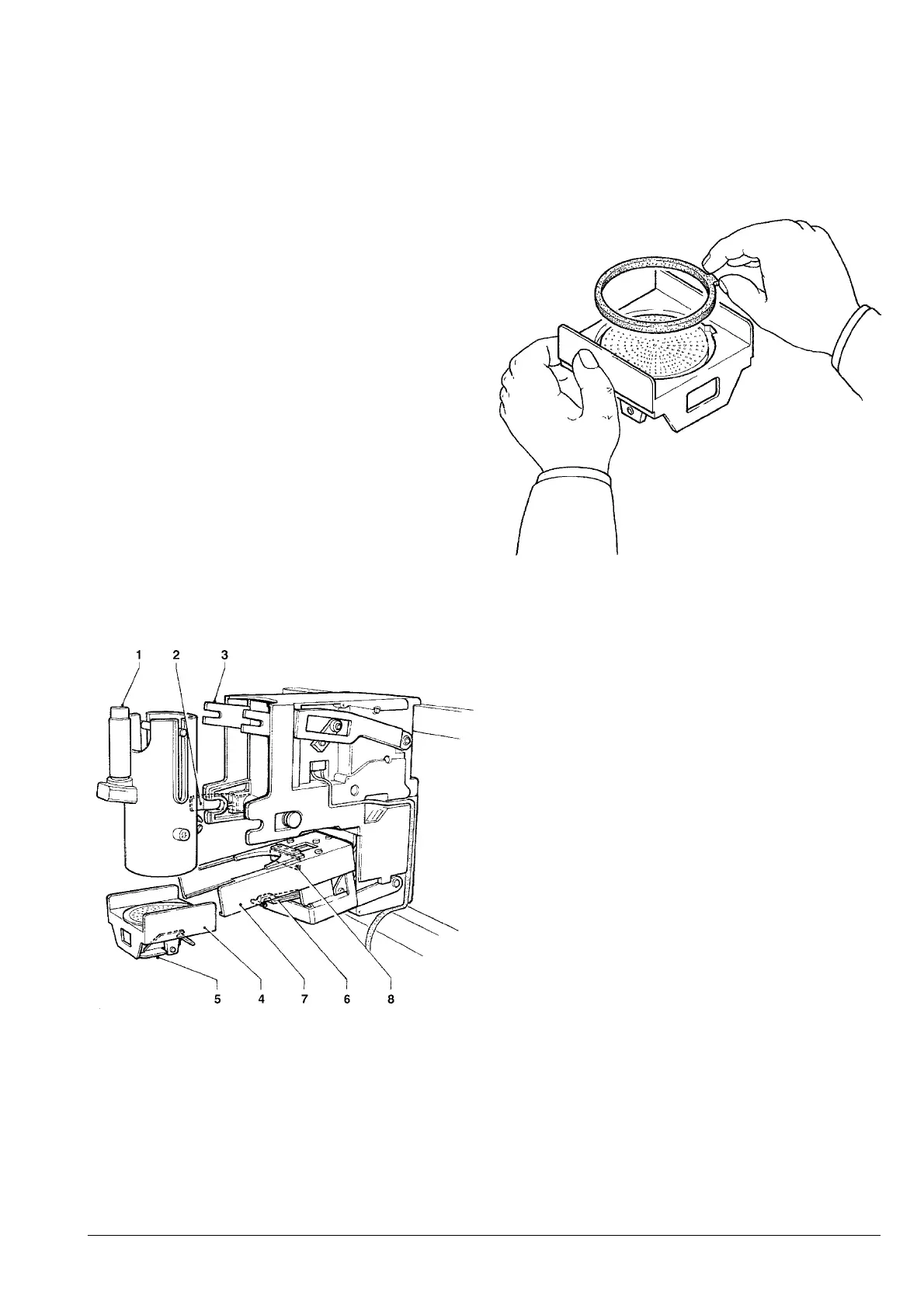

- Disconnect the hose from the mixer and remove the

mixer (9-1) from the brewing cylinder.

- Disengage the cylinder from the assembly by pulling the

release lever (9-2) and slide it out of the piston control

fork (9-3) by pulling it outwards.

- Slide out the piston from the cylinder.

- Extract the sliding filter holder (9-4) from the guide (9-

7) releasing the link (9-6) from the stop lever (9-5).

- Extract the scraper assembly (9-8).

- Wash all parts with mild detergent, being sure that all

visible residue and product layers are mechanically

removed, using a brush if necessary.

- Soak them for approx. 20 minutes in a container filled with

a chlorine-based detergent similar to the one used for the

mixers.

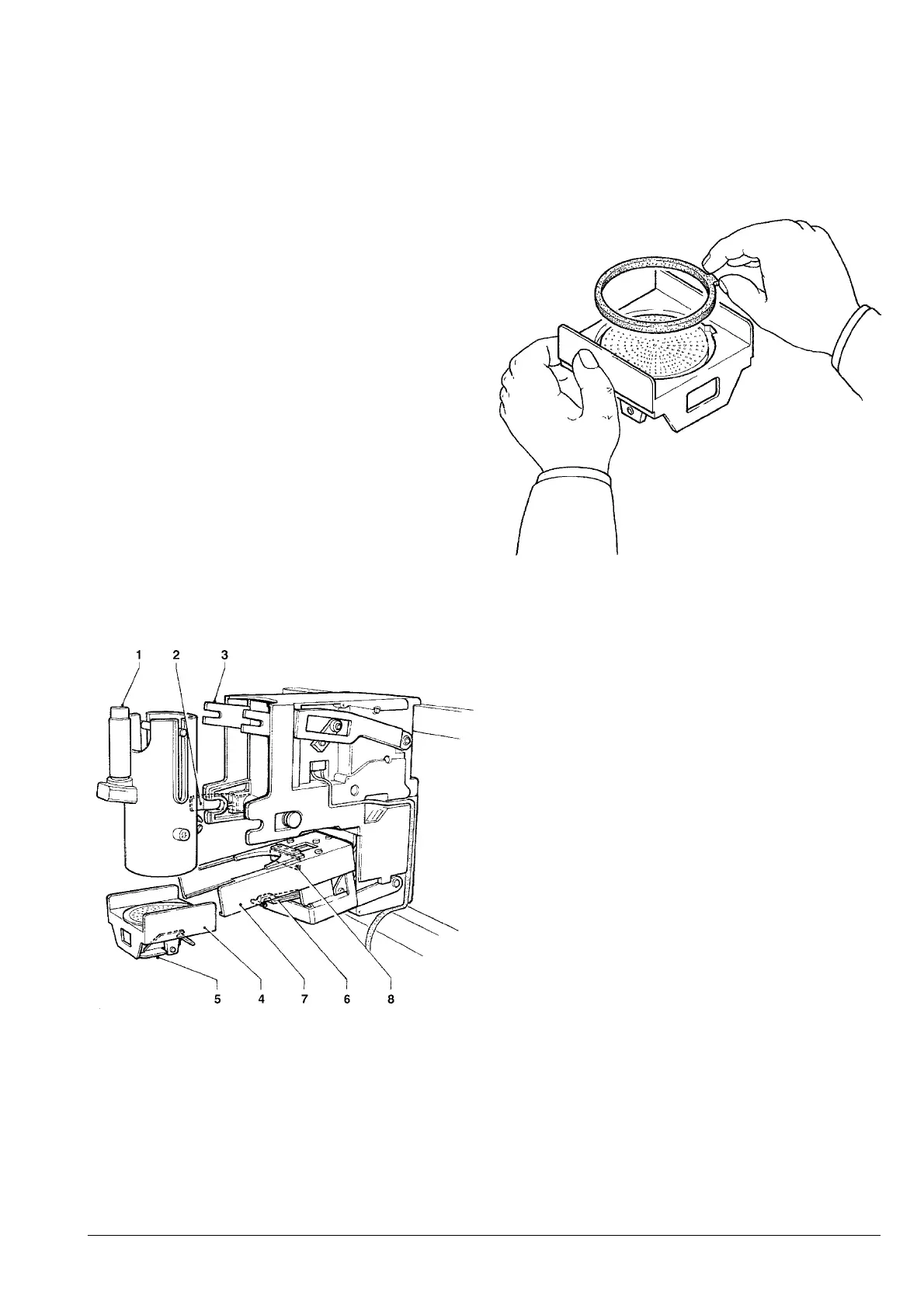

Fig. 10

Do not use screwdrivers or any other sharp objects

against the filter holder seal and do not place the seal

on surfaces which may damage it.

If the metal filter is clogged, it should be replaced or

cleaned with a specific product.

To remove the metal filter, first pull out the seal from its

edge (see fig. 10).

The filter must be cleaned at least every 2,500 selections.

To reassemble the brewer unit follow the above instruction

in the reverse order, making sure that the seal is installed

before the filter.

REPLACING THE FILTER CARTRIDGE

Every 30,000 drink selections or every 6 months, the

mains metal filter cartridge should be replaced according

to the procedure described in section "Installing the filter

cartridge".

SUSPENDING FROM USE

If for any reason the machine is switched off for a period

exceeding the use-by date of the products, the following will

be necessary:

- completely empty the containers and thoroughly wash

them with the chlorine-based detergents used to clean the

mixers.

- completely empty the air-break and the instant product

boiler, loosening the clamp on the hose.

Before reinstating the machine, the cleaning and

sanitising procedure described in the section "Yearly

sanitising" should be carried out.

Fig. 9

1 - Mixer

2 - Cylinder release lever

3 - Piston control lever

4 - Sliding filter holder

5 - Control link

6 - Filter holder release lever

7 - Guide

8 - Scraper assembly

Loading...

Loading...