Continued Page 10.2

10 DISMANTLING AND ASSEMBLY

OF THE ROTATING PARTS

PAGE

10.1R

revision: 1 date name signed

substitute for the issue issued 19.12.05 Mangel

dated 25.06.03 approved 20.12.05 Denk

text no. 30100

released 20.12.05 Denk

copy to:

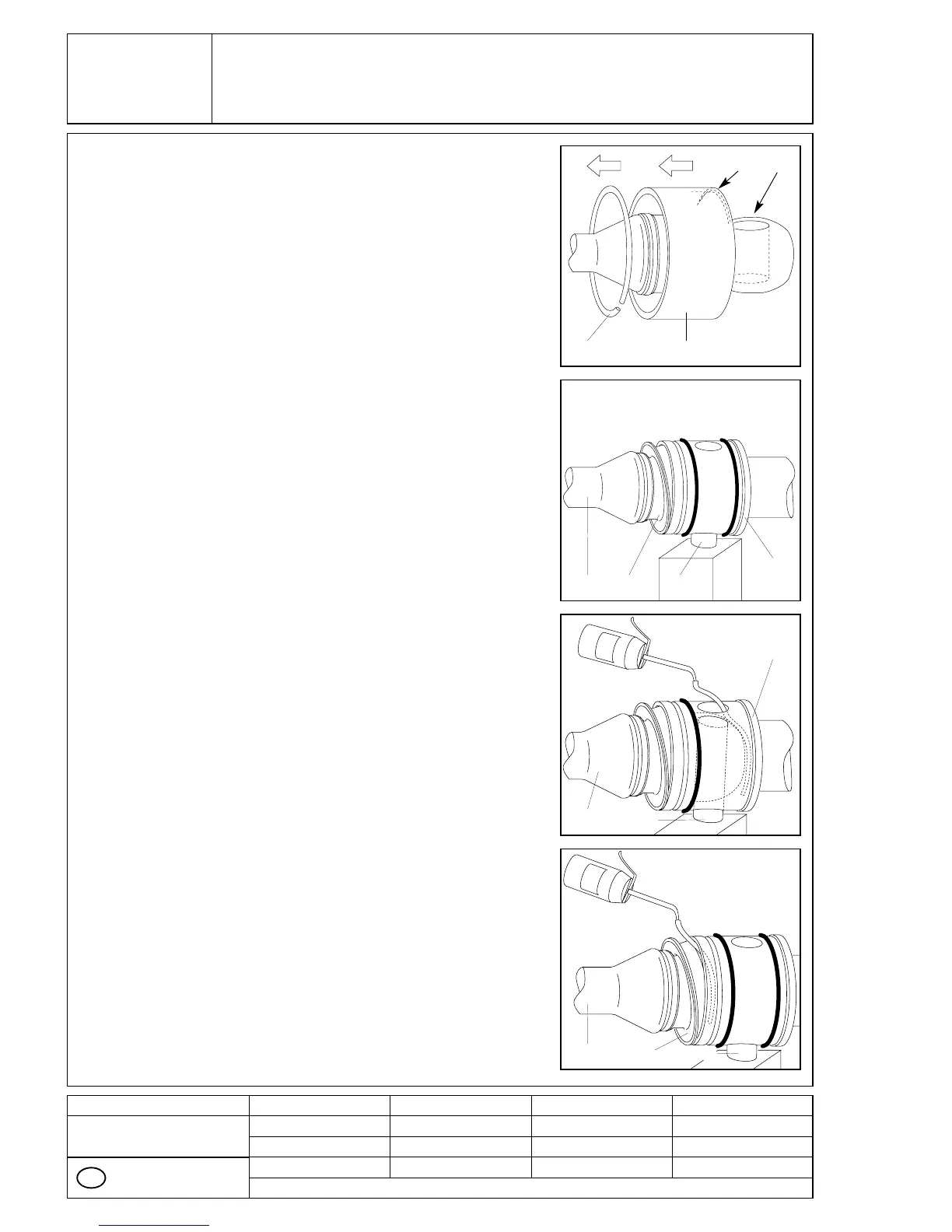

Basic joint size NM021 - NM105:

Slip the circlip (5065) on to the coupling rod (1998).

Slide the sleeve (5115) on to coupling rod (1998) so

the inside diameter of chamfering (A) is being pla-

ced towards the coupling rod (1998) extension.

Chamfering (A) will later on ease the installation

over the O-rings (8060).

Orient the head of coupling rod (1998) until it is in

vertical position for the bore (B) for the pin (5075).

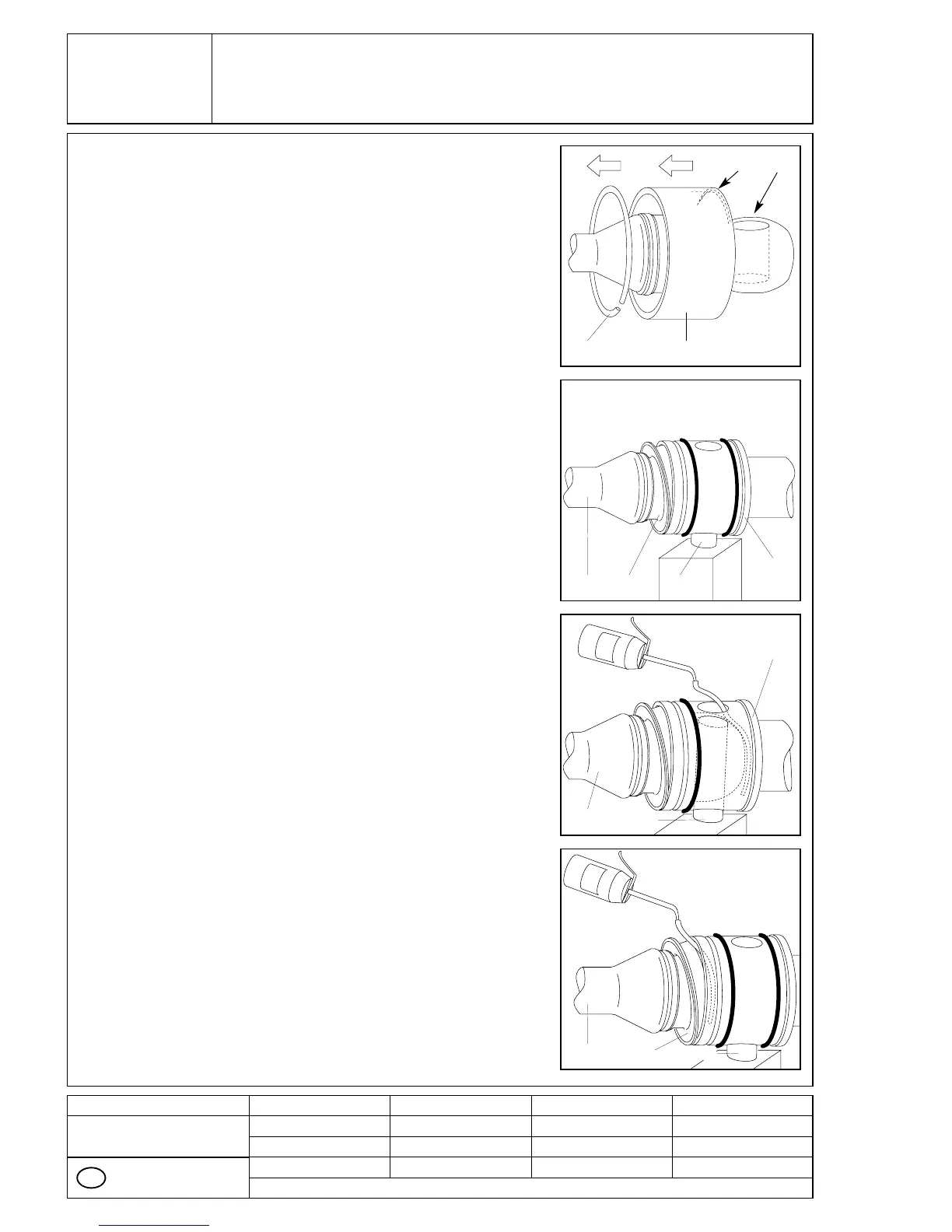

Slide the coupling rod (1998) with SM-pin joint seal

(8235) into the bore of rotor (1999) or connecting

shaft (1050) and insert the pin (5075) from below and

push up to the upper edge of coupling rod (1998).

Support the pin (5075) against dropping out.

Slide the SM-pin joint seal (8235) into the rotor

(1999) or connecting shaft (1050) only from below,

and in a slightly slanted position.

For lubrication, use an oil can which should be

fitted with a thin plastic hose having an outside dia-

meter of not more than 4 mm.

Insert this hose into the upper oil port opening in

the rotor (1999) or connecting shaft (1050). Then

slide the hose end past the coupling rod (1998)

all the way down to the bottom section of the rotor

head (1999) or connecting shaft (1050).

Slowly fill with lubricating oil up to the filling port.

Pull the hose out.

Then insert the hose end through the small gap on

the topside of SM-pin joint seal (8235) and guide it

down to the bottom of the hollow space between

coupling rod (1998) and SM-pin joint seal (8235).

Slowly fill with lubricating oil up to the gap.

■

■

■

■

5065

1998

1998

1998

8235 5075

5075

8235 5075

1050

1999

1050

1999

5115

A B

GB

Loading...

Loading...