XPS-Q8 Controller Motion Tutorial

14.0 Control Loops

14.1 XPS Servo Loops

14.1.1 Servo structure and Basics

The XPS controller can be used to control a wide range of motion devices, which are

categorized by the XPS as “positioners”. Within the structure of the XPS' firmware, a

“positioner” is defined as an object with an associated profile (trajectory), a PID

corrector, a motor interface, a driver, a stage and an encoder.

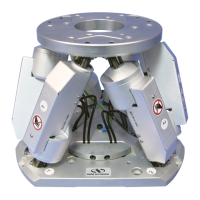

The general schematic of a positioner servo loop is below.

Figure 51: Servo structure and Basics.

The calculations done by the “servo loop” result in a voltage output from the controller

that is applied to the driver, which can be either any of Newport's Universal drive

modules or to an external driver through the XPS pass-through module. Depending on

the corrector loop type selected, the level of this output voltage can be the result of two

gain factors, the PID corrector and the FeedForward loop. The XPS has imbedded

configuration files that provide optimized corrector loop settings for all Newport stages.

Non-Newport stages may need to be assigned a specific corrector loop setting during

the set-up process. In addition to the two main gain loops the XPS also adds filtering

and error compensation parameters to this servo loop to improve system response and

reliability.

The profiler (Trajectory Generator) within the controller calculates in real time, the

position, velocity, and acceleration/deceleration that the positioner must follow to reach

its commanded position (Setpoint Position). This profile is updated at a rate of 2.5 kHz.

The PID corrector then compares the SetpointPosition, as defined by the profiler, and

the current position, as reported by the positioner's encoder, to determine the current

following error. The PID corrector then outputs a value that the controller uses to

maintain, increase or decrease the output voltage, which is applied to the driver. This

loop is updated at a rate of 8 kHz. The adjustment of the PID parameters allows users to

optimize the performance of their positioner or system by increasing or decreasing the

responsiveness of the output to increasing or decreasing following errors. Refer to the

section 14.3 on PID tuning for more information and tips on PID tuning. The PID

corrector loop and trajectory generation loop rates have been optimized to provide the

highest level of precision. In most applications the critical control loop is the PID

corrector since it has the most significant impact on positioning performance. Because

of this, the PID loop is updated 4 times (10/2.5) during each profiler cycle to improve

profile execution and minimize following errors.

The Feed-Forward gain generates a voltage output to the driver that is directly

proportional to the input. The purpose of this gain is to generate a movement of the

positioner as close as possible to the desired move that is independent of the encoder

feedback loop. Adding this Feed-Forward gain can help reduce any encountered

following errors and thus requires less compensation by the PID gain corrector. For

171 XPSDocumentation V1.4.x (EDH0301En1060 — 10/17)

Loading...

Loading...