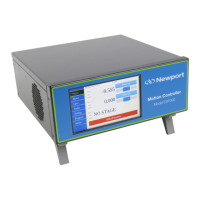

XPS-Q8 Controller User’s Manual

The XPS-DRV02 is a software configurable PWM amplifier for 3-phase brushless

motors. It has been optimized for performance with XM, ILS-LM, IMS-LM linear

motor stages and RGV direct drive rotation stages. The XPS-DRV02 supplies a 100

kHz PWM output with a maximum output current of 5 A per phase and 44 Vpp. The

XPS-DRV02 requires 1 Vpp analog encoder input signals used also for motor

commutation. Motor initialization is done by a special routine measures the magnetic

position without the need for Hall or other sensors.

The XPS-DRV03 is a fully digital, programmable PWM-amplifier that has been

optimized for use with high-performance DC motors. The high switching frequency of

100 kHz and appropriate filter technologies minimize noise to enable ultra-precision

positioning in the nm-range. The XPS-DRV03 supplies a maximum current of 5 Amps

and 48 Volts. It is capable of driving DC motors in velocity mode (for motors with

tachometer), in voltage mode (for motors without tachometer), and in current mode (for

torque motors). All parameters are programmable in physical units (for instance the

bandwidth of the velocity loop). Furthermore, the XPS-DRV03 features individual

limits for the rms current and the peak current.

The XPS-DRVP1 is a programmable driver card for Newport's NanoPositioning line of

piezoelectric stack stages. This driver card has a range of -10 to 150 VDC with 30 mA

continuous. The drive features a 4 kHz update rate and resolution of 16 bits ADC and

DAC. It also accepts strain gage position feedback.

The XPS-DRV00 and XPS-DRV00P pass-through module can be used to pass control

signals to other external third-party amplifiers (drivers). By setting the controller’s dual

DAC output to either analog position, analog stepper position, analog velocity, analog

voltage or analog acceleration (including sine commutation), the XPS is capable of

controlling almost any motion device including 3

rd

party brushless motors and voice

coils.

In addition to conventional digital AquadB feedback encoder interface, the XPS

controller also features a high-performance analog encoder input (1 Vpp Heidenhain

standard) on each axis. An ultra-high resolution, very low noise, encoder signal

interpolator converts the sine-wave input to an exact position value with a signal

subdivision up to 32,768-fold. For example, when used with a scale with 4 µm signal

period the resolution can be as fine as 0.122 nm. This interpolator can be used for

accurate position feedback on the servo corrector of the system. An additional hardware

interpolator with 40 MHz clock frequency and programmable signal subdivision up to

200-fold is used for synchronization purposes. This fast interpolator latches the position

directly with less than 50 ns latency and provides a much higher level of precision for

synchronization than alternative time based systems. Unlike most high-resolution

multiplication devices, the XPS interpolators do not compromise positioning speed.

With a maximum input frequency ranging from 180 kHz to 400 kHz (depending on the

interpolation factor), the maximum speed of a stage with a 20 µm signal period scale

can be up to 3.6 m/s.

2.3 Compatible Newport Positioners and Drive Power Consumption

The list of all compatible Newport positioners and the corresponding drive module

needed is available from the Newport catalog or at www.newport.com

XPSDocumentation V1.4.x (EDH0301En1060 — 10/17) 8

Loading...

Loading...