4-Agendosuldadodelcodulofune

delcarrellolatoopposto(fig.43),re

-

golarel’altezzadelcarrellostessoin

modocherisulti10mm.piùaltodel

carrellolatocomando(fig.58);que

-

stoalfinedicompensarel’allunga

-

mentodellafunesottocarico.Quindi

bloccareilcodulofunesulcarrello

latooppostoserrandol’apposito

controdado.

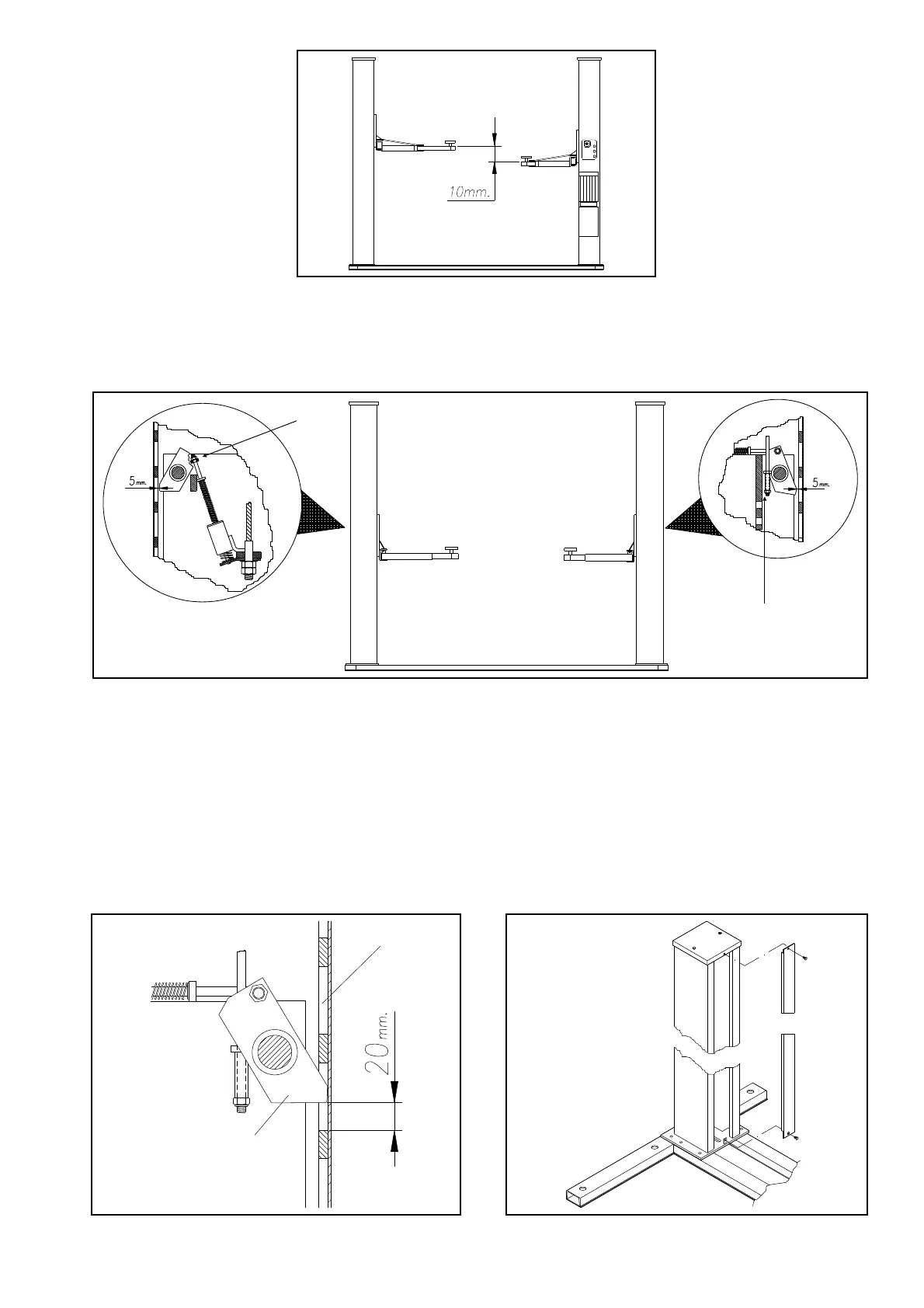

Fig.58 Regolazionedeicarrelli

5-Ilcostruttorefornisceilponteconimartellettidisicurezzapreta

-

rati.Verificarecomunqueconuncalibrocheladistanzafraimar

-

tellettidisicurezzaeleasteforatesiadi5mmcomeindicatoin

fig.59.Seladistanzanonrisultasseesseretale,agiresuidadidi

regolazione(AeB,fig.59)finoaportarlaalvalorerichiesto.

Fig.59 Regolazionedeimartelletti

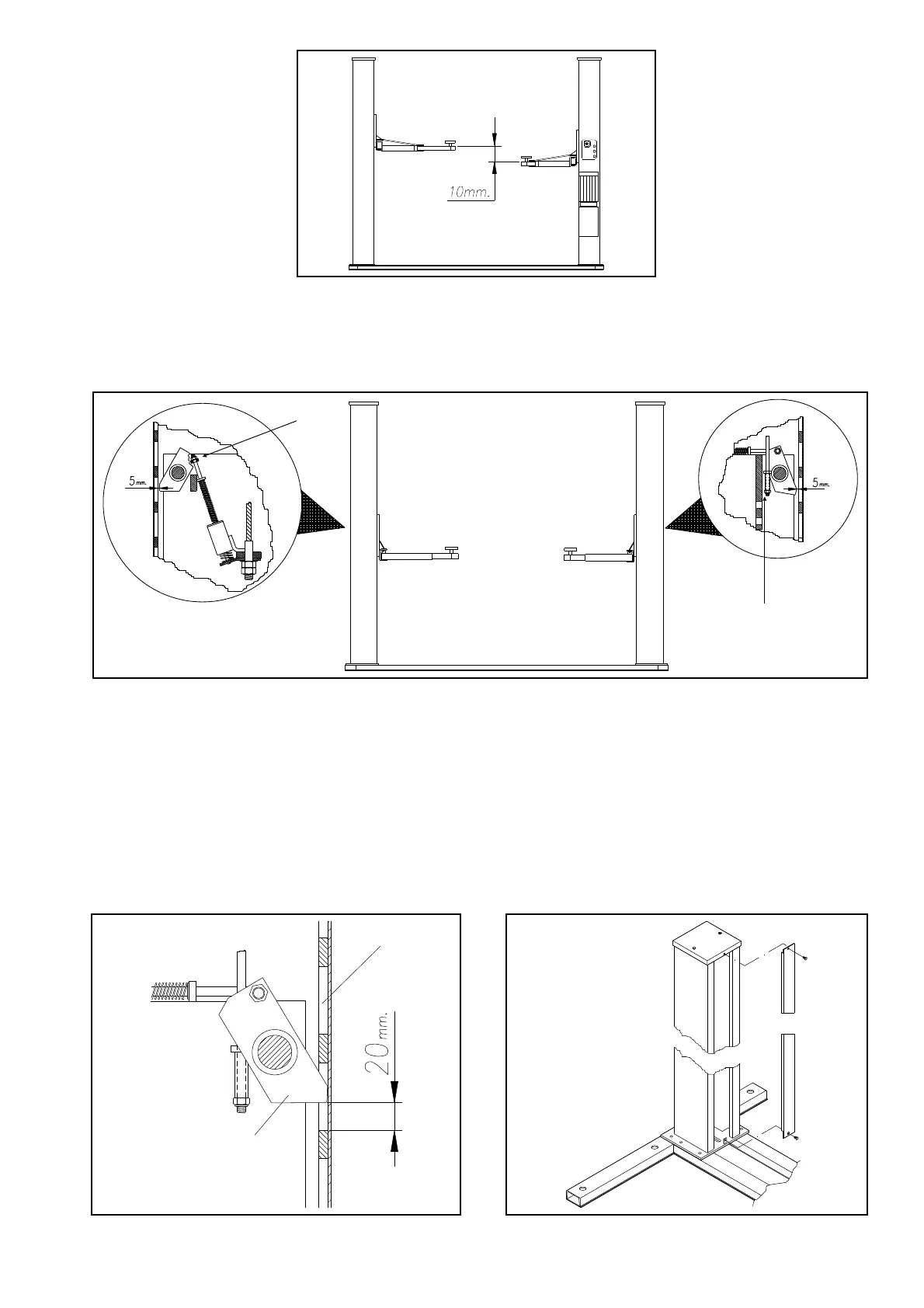

6-Verificarecheallamassimaaltezzaladistanzatraimartelletti(1

Fig.59A)eleasole(2Fig.59A)dell’astadisicurezzasulle2co

-

lonnesia20mmminimodalsuoappoggio,unamisurainferirore

nondarebbeiltempoallasicurezzadiruotarerimanendoaggan

-

ciataall’asta.Senecessarioregolareilfinecorsasalita.

7-Montareicarteranterioridiprotezionecolonnafissandoliconle

vitiTEM8x16elerelativerondelle(fig.60).

8-Alimentareilponteeverificareilcorrettofunzionamentodelmi

-

crointerruttorefunepostonelbasamento.

9-Fissarelapedanadicoperturadelbasamentomedianteleviti

TSPEIM6x14.

Fig.59AMontaggiodeicarter Fig.59ACasingassembly

4-Usingthenutoftheoppositeside

carriagecableend(fig.43),adjustthe

heightofthecarriagesothatitis10

mmhigherthanthecarriageonthe

commandside(fig.58).Thiscompen

-

satesfortheelongationofthecable

underload.Thenlockthecableend

ontheoppositecarriagesidebytigh

-

teningthespecialcounternut.

Fig.58Carriageadjustment

5-Themanufacturersuppliestherackwiththesafetywedges

pre-calibrated.Inanycase,useagaugetocheckthatthedistance

betweenthesafetywedgesandthedrilledrodsis5mmasshown

infig.59.Ifthedistanceisnotcorrect,usetheadjustmentnuts(A

andB,fig.59)toobtaintherequiredvalue.

Fig.59 Safetywedgeadjustment

6-Checkthattothemaximumheightthedistancebetweenthe

wedges(1Fig.59A)andtheslots(2Fig.59A)ofthesafetystroke

onthe2columnsis20mmminimumfromsupport,aninferior

distancewouldnotgivethetimetothesafetywedgetorotate

keepinghookedtothestroke.Ifnecessaryregulatetheriselimit

switch.

7-Mountthefrontpostprotectioncasings,attachingthemwith

screwsTEM8x16andtherelativewashers(fig.60).

8-Feedtherackandverifythatthecablemicroswitchinstalledin

thebaseoperatescorrectly.

9-AttachthebasecoverplateusingscrewsTSPEIM6x14.

Fig.60Montaggiodeicarter Fig.60Casingassembly

29

A

B

1

2

Loading...

Loading...