• For compliance with the UL standard requirements, be sure to perform wiring according to

2-4-2 UL/cUL Standards Cautions on page 2-83, which includes the use of UL-compliant specified

fuses and specified wiring materials.

•

Tighten the terminal block screws with the specified torque. Weak tightening may result in a short-

circuiting accident or fire. Conversely, overtightening these screws may cause damage to the termi-

nal block or the inverter.

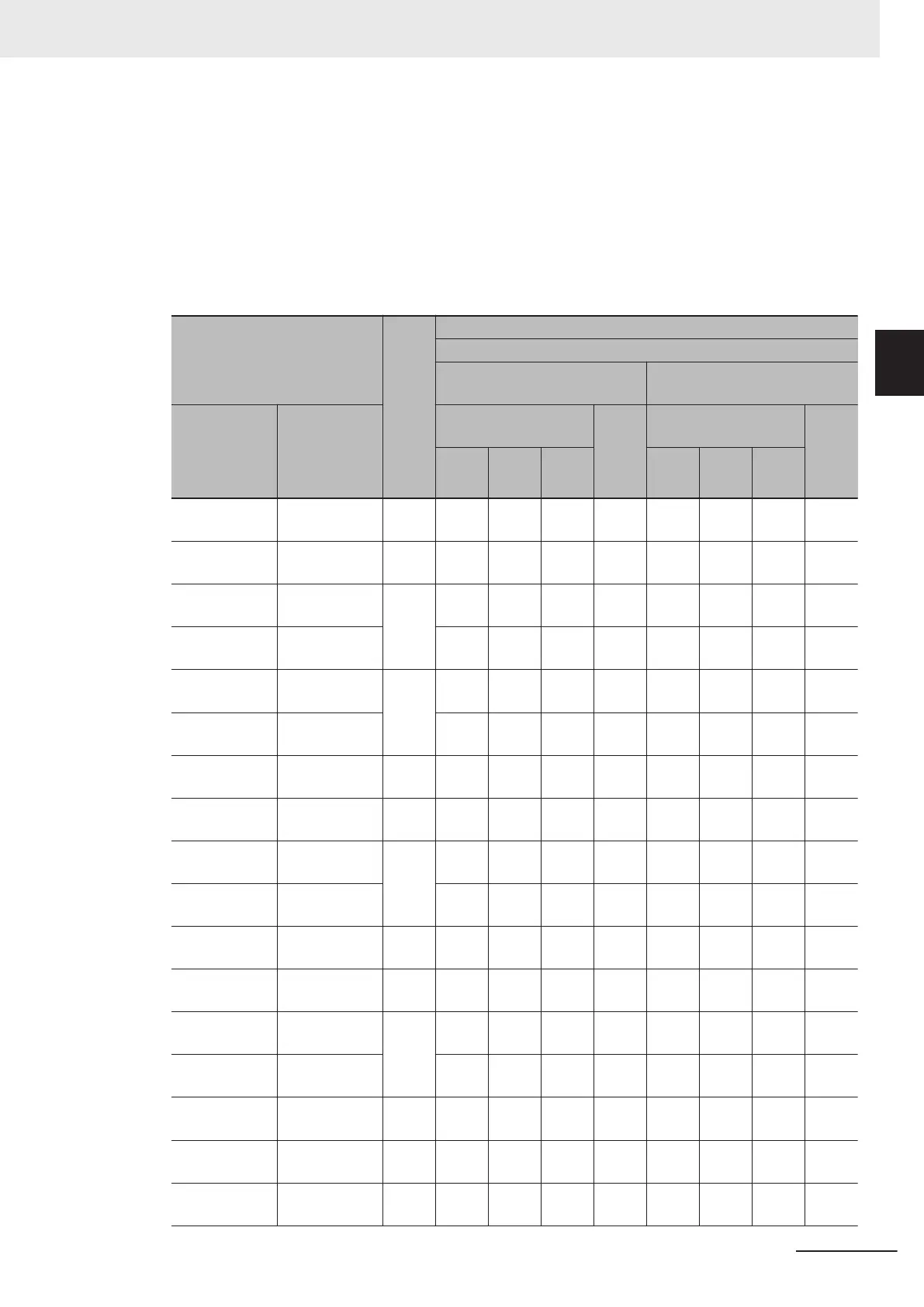

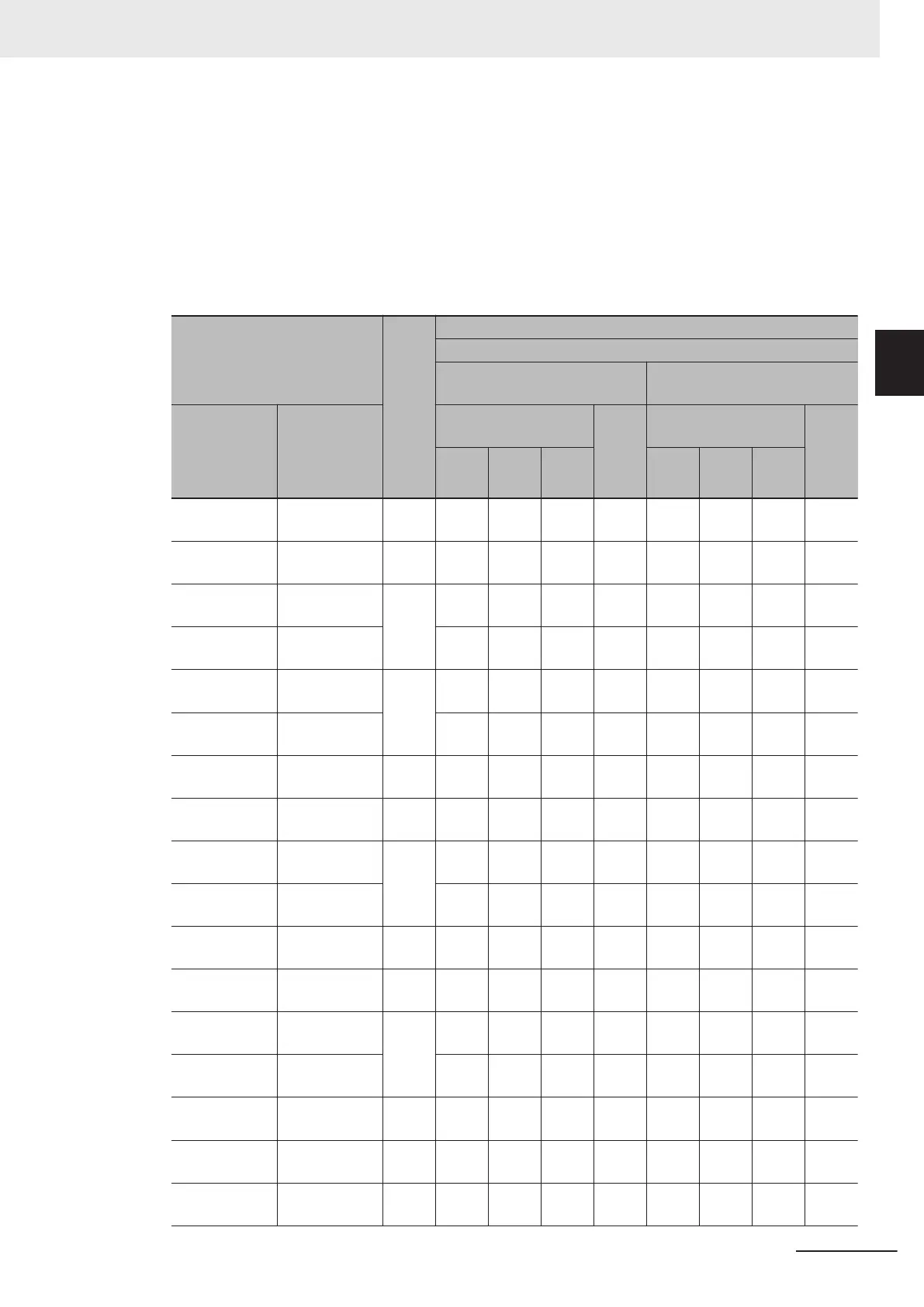

Three-phase 200-V class (Panel internal temperature 50°C or less)

Model

Maxi-

mum

appli-

cable

motor

ca-

paci-

ty

[kW]

Recommended wire size [mm2]

Main power supply input (L1/R, L2/S, L3/T)

When DC reactor (DCR) is

used

Without DC reactor

HHD mode HND mode

Allowable tempera-

ture (Note 1)

Cur-

rent

value

[A]

Allowable tempera-

ture (Note 1)

Cur-

rent

value

[A]

60°C 75°C 90°C 60°C 75°C 90°C

3G3M1-

A2001-ECT

- 0.1 2.0 2.0 2.0 0.6 2.0 2.0 2.0 1.1

3G3M1-

A2002-ECT

3G3M1-

A2001-ECT

0.2 2.0 2.0 2.0 0.9 2.0 2.0 2.0 1.8

- 3G3M1-

A2002-ECT

0.4 2.0 2.0 2.0 1.6 2.0 2.0 2.0 2.6

3G3M1-

A2004-ECT

- 2.0 2.0 2.0 1.6 2.0 2.0 2.0 3.1

- 3G3M1-

A2004-ECT

0.75

2.0 2.0 2.0 3.0 2.0 2.0 2.0 4.9

3G3M1-

A2007-ECT

- 2.0 2.0 2.0 3.0 2.0 2.0 2.0 5.3

- 3G3M1-

A2007-ECT

1.1 2.0 2.0 2.0 4.3 2.0 2.0 2.0 6.7

3G3M1-

A2015-ECT

- 1.5 2.0 2.0 2.0 5.7 2.0 2.0 2.0 9.5

- 3G3M1-

A2015-ECT

2.2 2.0 2.0 2.0 8.3 2.0 2.0 2.0 12.8

3G3M1-

A2022-ECT

- 2.0 2.0 2.0 8.3 2.0 2.0 2.0 13.2

- 3G3M1-

A2022-ECT

3 2.0 2.0 2.0 11.7 3.5 2.0 2.0 17.9

3G3M1-

A2037-ECT

- 3.7 2.0 2.0 2.0 14.0 5.5 2.0 2.0 22.2

- 3G3M1-

A2037-ECT

5.5 3.5 2.0 2.0 19.9 8.0 3.5 2.0 28.5

3G3M1-

A2055-ECT

- 5.5 2.0 2.0 21.1 8.0 3.5 3.5 31.5

3G3M1-

A2075-ECT

3G3M1-

A2055-ECT

7.5 8.0 3.5 2.0 28.8 14.0 5.5 5.5 42.7

3G3M1-

A21

10-ECT

3G3M1-

A2075-ECT

1

1 14.0 5.5 5.5 42.2 22.1 14.0 8.0 60.7

3G3M1-

A2150-ECT

3G3M1-

A2110-ECT

15

22.0 14.0 8.0 57.6 38.0 14.0 14.0 80.0

2 Design

2-19

M1 Series EtherCAT Type User’s Manual (I670)

2-3 Wiring

2

2-3-4 Wiring for Main Circuit Terminals

Loading...

Loading...