10-5

10-2 Realtime Autotuning

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

10

Adjustment Functions

Precautions for Correct Use

Unusual noise or vibration may occur until the load inertia is estimated or the adaptive filter

stabilizes after startup, immediately after the first servo ON, or when the Realtime Autotuning

Machine Rigidity Selection (Pn003) is increased. This is not an error if it disappears right away. If

the unusual noise or vibration, however, continues for 3 or more reciprocating operations, take the

following measures in any order you can.

Write the parameters used during normal operation to the EEPROM.

Lower the Realtime Autotuning Machine Rigidity Selection (Pn003).

Manually set the notch filter.

Once unusual noise or vibration occurs, Inertia Ratio (Pn004), Torque Command Value Offset

(Pn607), Forward Direction Torque Offset (Pn608), and Reverse Direction Torque Offset (Pn609)

may have changed to an extreme value. In this case, also take the measures described above.

Out of the results of realtime autotuning, the Inertia Ratio (Pn004), Torque Command Value Offset

(Pn607), Forward Direction Torque Offset (Pn608) and Reverse Direction Torque Offset (Pn609)

are automatically saved to the EEPROM every 30 minutes. Realtime autotuning will use this

saved data as the default setting when the power supply is turned OFF and turned ON again.

The parameter will automatically be set based on the Realtime Autotuning Machine Rigidity

Setting (Pn003) if realtime autotuning is enabled.

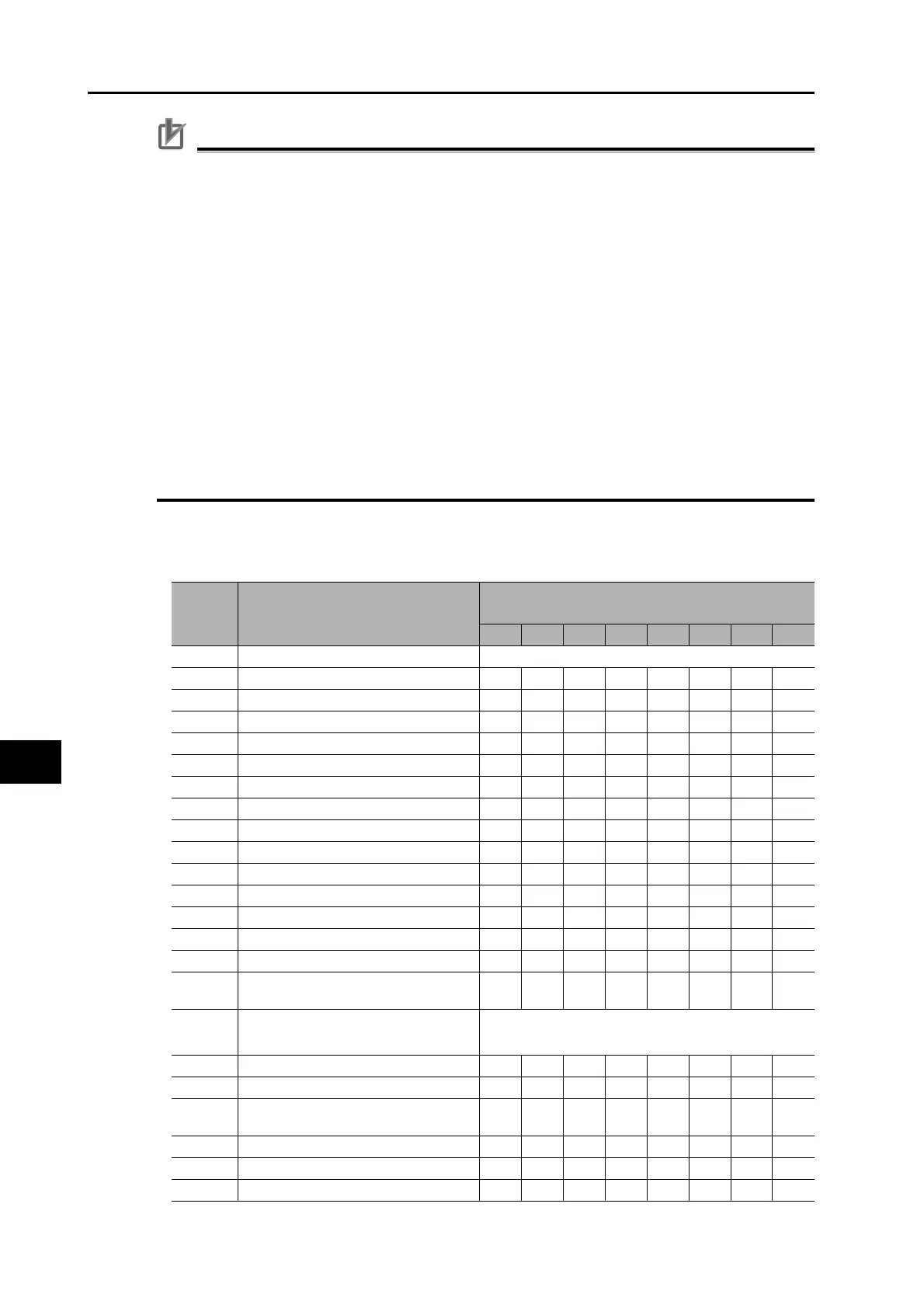

Realtime Autotuning (RTAT) Parameter Table

Parameter

number

Parameter name

AT Machine Rigidity Setting (Pn003)

0 1 2 3 4 5 6 7

Pn004 Inertia Ratio Estimated load inertia ratio

Pn100 Position Loop Gain 20 25 30 40 45 55 75 95

Pn101 Speed Loop Gain 15 20 25 30 35 45 60 75

Pn102 Speed Loop Integral Time Constant 3700 2800 2200 1900 1600 1200 900 700

Pn103 Speed Feedback Filter Time Constant 0 0000000

Pn104 Torque Command Filter Time Constant 1

*1

1500 1100 900 800 600 500 400 300

Pn105 Position Loop Gain 2 25 30 40 45 55 70 95 120

Pn106 Speed Loop Gain 2 15 20 25 30 35 45 60 75

Pn107 Speed Loop Integral Time Constant 2

*2

10000 10000 10000 10000 10000 10000 10000 10000

Pn108 Speed Feedback Filter Time Constant 2 0 0000000

Pn109 Torque Command Filter Time Constant 2

*1

1500 1100 900 800 600 500 400 300

Pn110 Speed Feed-forward Amount 300 300 300 300 300 300 300 300

Pn111

Speed Feed-forward Command Filter

50 50 50 50 50 50 50 50

Pn112 Torque Feed-forward Amount 0 0000000

Pn113 Torque Feed-forward Command Filter 0 0000000

Pn114

Gain Switching Input Operating Mode

Selection

11111111

Pn115 Switching Mode in Position Control

Gain Switching Enable Mode: 10

Gain Switching Disable Mode: 0

Pn116

Gain Switching Delay Time in Position Control

30 30 30 30 30 30 30 30

Pn117 Gain Switching Level in Position Control 50 50 50 50 50 50 50 50

Pn118

Gain Switching Hysteresis in Position

Control

33 33 33 33 33 33 33 33

Pn119 Position Gain Switching Time 33 33 33 33 33 33 33 33

Pn120 Switching Mode in Speed Control 0 0000000

Pn121

Gain Switching Delay Time in Speed Control

00000000

Loading...

Loading...