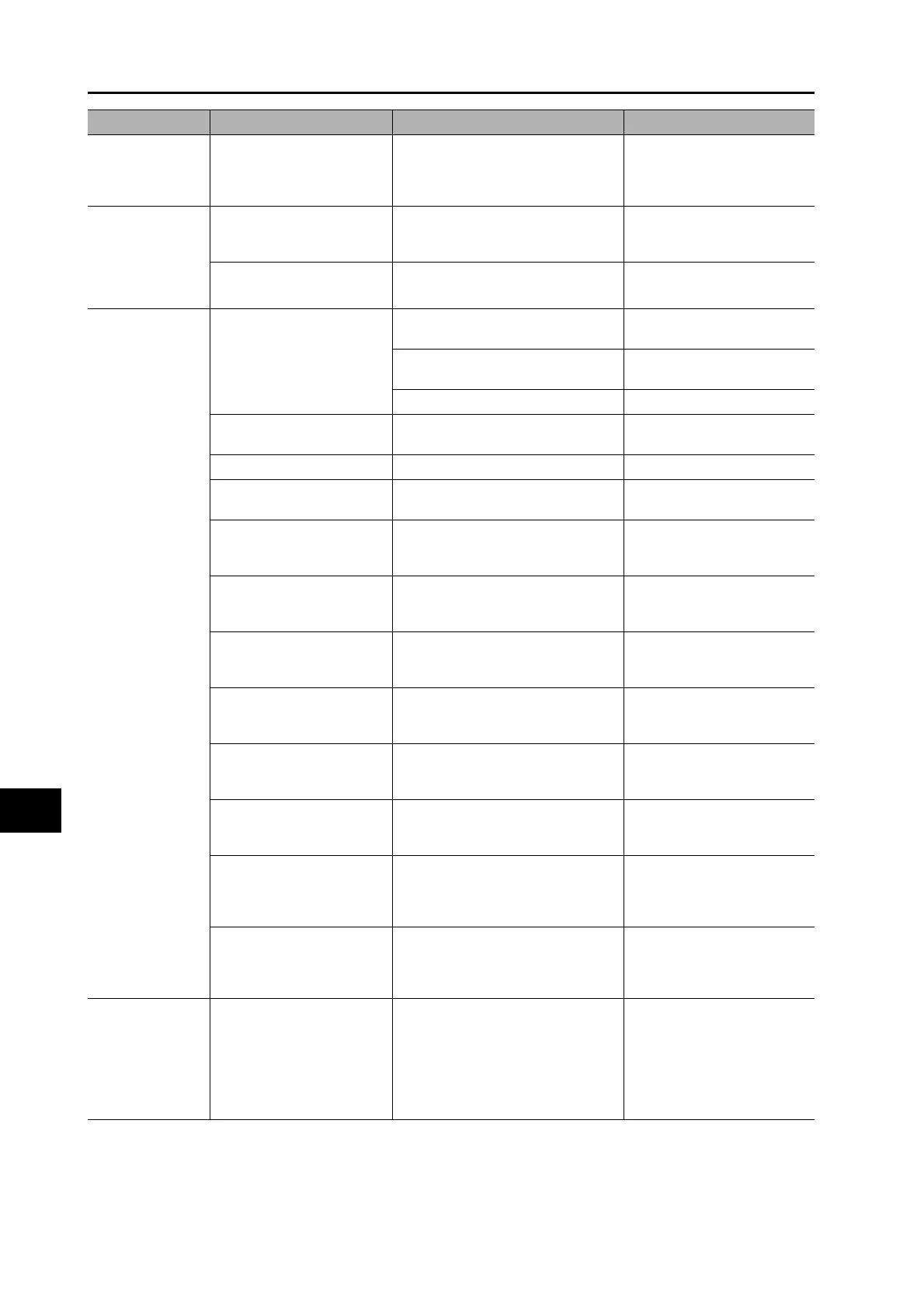

11-25

11-4 Troubleshooting

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

11

Troubleshooting and Maintenance

The Servomotor

holding brake is

ineffective.

Power is supplied to the holding

brake.

Check whether power is supplied to the

holding brake.

Configure a circuit that cuts power

supply to the holding brake when the

motor stops and the load is held by

the holding brake.

The motor does not

stop or is hard to stop

even if the operation

command (RUN) is

turned OFF while the

motor is rotating.

The load inertia is too large. Check the following:

·Is the load too large?

·

Is the motor rotation speed too high?

Review the load conditions, and

replace the Servomotor and Servo

Drive with appropriate models.

The stop circuit failed. − Replace the Servo Drive.

The motor is

producing unusual

noises or the

machine is vibrating.

(Continued on next

page)

There are problems with the

machine's installation.

Check to see if the Servomotor's

mounting screws are loose.

Retighten the mounting screws.

Check whether the axes are misaligned in

the coupling.

Align the coupling.

Check whether the coupling is unbalanced.

Adjust the coupling's balance.

There is a problem with the

bearings.

Check for noise or vibration around the

bearings.

Contact your OMRON dealer or

sales office.

The gain is wrong. − Perform manual tuning.

The Speed Feedback Filter Time

Constant (Pn103) is wrong.

Check the value set in Pn103. Return the set to 0 (default set) or

increase the set value.

Noise is entering into the control

I/O signal cable because the cable

does not meet specifications.

Check to see if the cable is a twisted-pair

cable or shielded twisted-pair cable with

core wires that are at least 0.08 mm dia.

Use a control I/O signal cable that

meets specifications.

Noise is entering into the control I/O

signal cable because the cable is

longer than the specified length.

Check the length of the control I/O signal

cable.

Shorten the control I/O signal

cable to 3 m or less.

Noise is entering into the cable

because the encoder cable does

not meet specifications.

Check to see if it is a shielded twisted-pair

cable with core wires that are at least 0.12

mm dia.

Use an encoder cable that meets

specifications.

Noise is entering into the encoder

cable because the cable is longer

than the specified length.

Check the length of the encoder cable. Shorten the encoder cable to less

than 50 m.

Noise is entering into the signal

lines because the encoder cable is

stuck or the sheath is damaged.

Check the encoder cable for damage. Correct the encoder cable's

pathway.

Excessive noise on encoder

cable.

Check to see if the encoder cable is

bound together with or too close to high-

current lines.

Install the encoder cable where it

won't be subjected to surges.

The FG's potential is fluctuating

due to devices near the

Servomotor, such as welding

machines.

Check for ground problems (loss of

ground or incomplete ground) at

equipment such as welding machines

near the Servomotor.

Ground the equipment properly

and prevent current from flowing

to the encoder FG.

Errors are being caused by

excessive vibration or shock on

the encoder.

There are problems with mechanical

vibration or Servomotor installation (such

as the precision of the mounting surface,

attachment, or axial offset).

Reduce the mechanical vibration

or correct the Servomotor's

installation.

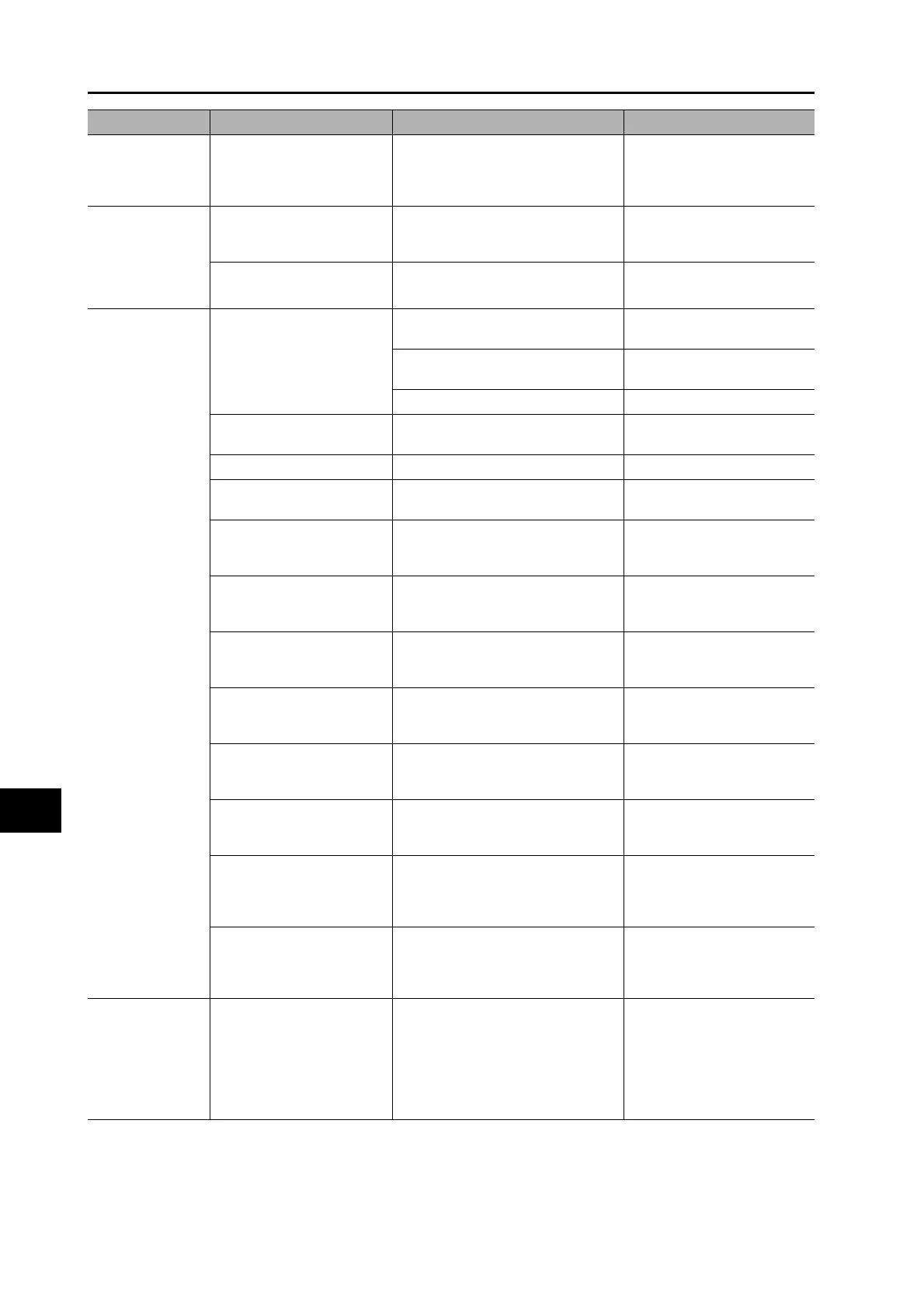

The motor is

producing unusual

noises or the

machine is vibrating.

(Continued from

previous page)

The machine and the motor are

resonating.

Check to see if the machine is resonating.

· Readjust the torque command

filter time constant.

· If there is resonance, set the

Notch Filter 1 Frequency

(Pn201), Notch Filter 1 Width

(Pn202), and Notch Filter 1

Depth (Pn203).

Symptom Probable cause Items to check Measures

Loading...

Loading...