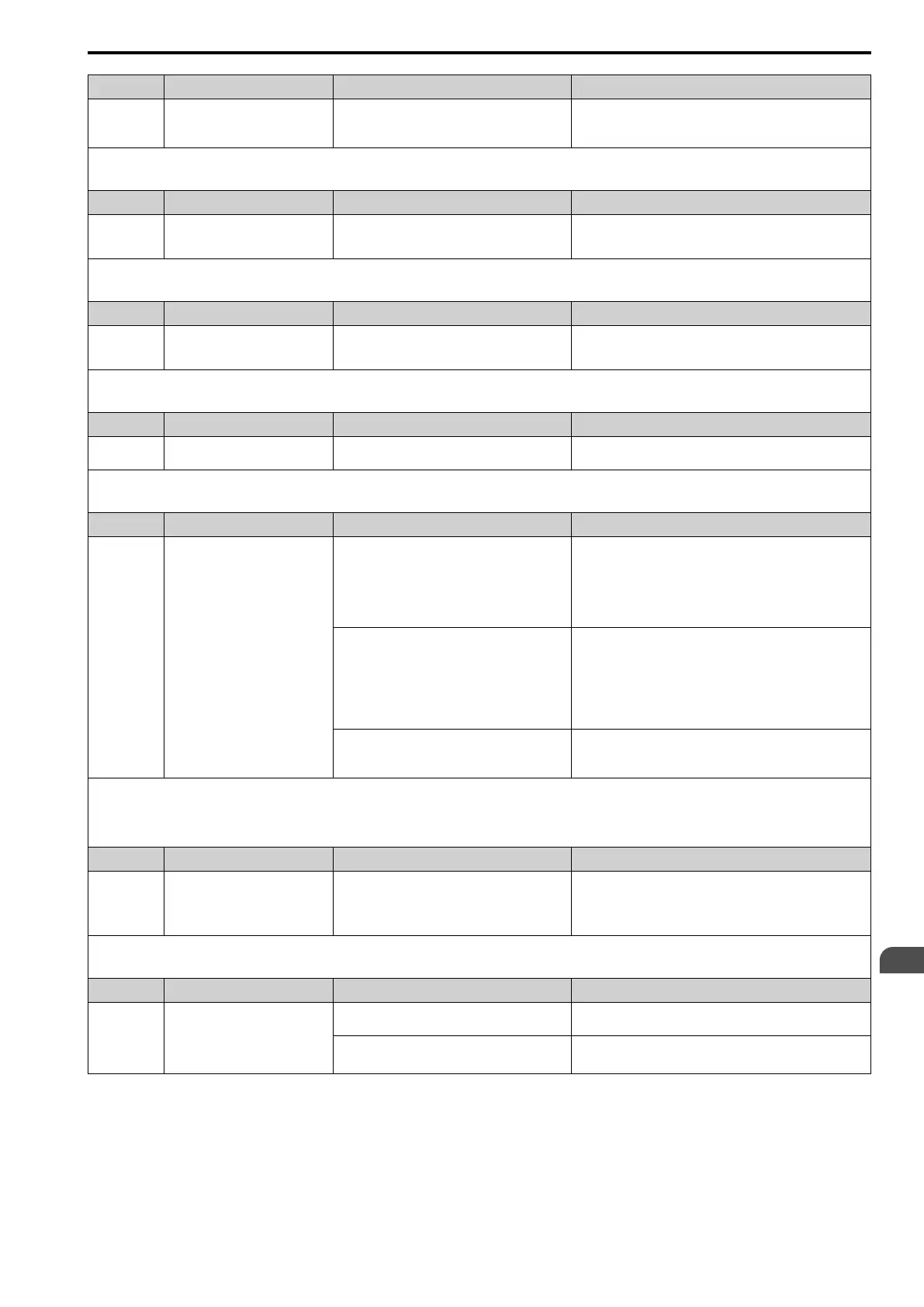

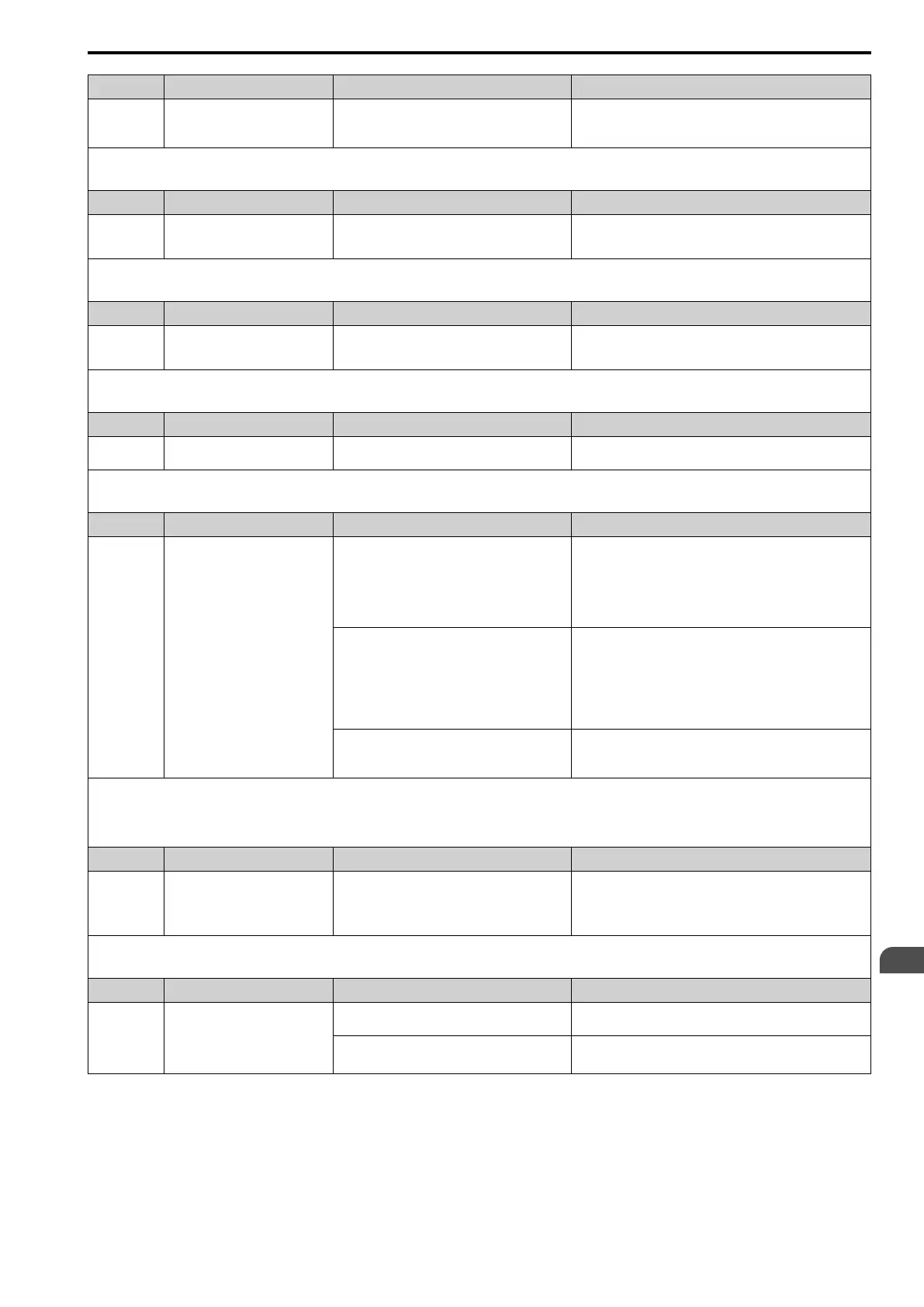

Troubleshooting

7

7.5 Minor Faults/Alarms

SIEPYEUOQ2A01A AC Drive Q2A Technical Manual 279

Code Name Causes Possible Solutions

LT-1 Cooling Fan Maintenance Time

The cooling fan is at 90% of its expected

performance life.

1. Use the procedures in this manual to replace the cooling fan.

2. Set o4-03 = 0 [Fan.Oper Setting = 0 h] to reset the cooling

fan operation time.

Note:

When the estimated performance life is expired, the terminal assigned to H2-01, H2-02, and H2-03 =63 [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-4CM

Funct Selection = Maintenance] will be ON.

Code Name Causes Possible Solutions

LT-2 Capacitor Maintenance Time

The capacitors for the main circuit and control

circuit are at 90% of expected performance life.

Replace the control board or the drive. For information about

replacing the control board, contact the manufacturer or your

nearest sales representative.

Note:

When the estimated performance life is expired, the terminal assigned to H2-01, H2-02, and H2-03 = 63 [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-

4CM Funct Selection = Maintenance] will be ON.

Code Name Causes Possible Solutions

LT-3

SoftChargeBypassRelay

MainteTime

The soft charge bypass relay is at 90% of its

expected performance life.

Replace the control board or the drive. For information about

replacing the control board, contact the manufacturer or your

nearest sales representative.

Note:

When the estimated performance life is expired, the terminal assigned to H2-01, H2-02, and H2-03 = 63 [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-

4CM Funct Selection = Maintenance] will be ON.

Code Name Causes Possible Solutions

LT-4 IGBT Maintenance Time (50%)

The IGBT is at 50% of its expected performance

life.

Check the load, carrier frequency, and output frequency.

Note:

When the estimated performance life is expired, the terminal assigned to H2-01, H2-02, and H2-03 = 63 [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-

4CM Funct Selection = Maintenance] will be ON.

Code Name Causes Possible Solutions

oH Heatsink Overheat

The ambient temperature is high and the heatsink

temperature is more than the L8-02 [Overheat Alm

Level].

• Measure the ambient temperature.

• Increase the airflow around the drive.

• Install a cooling device (cooling fan or air conditioner) to

lower the ambient temperature.

• Remove objects near the drive that are producing too much

heat.

There is not sufficient airflow around the drive. • Give the drive the correct installation space as shown in the

manual.

• Make sure that there is sufficient circulation around the control

panel.

• Examine the drive for dust or other unwanted materials that

could clog the cooling fan.

• Remove unwanted materials that prevent air circulation.

The internal cooling fan or fans have stopped. 1. Use the procedures in this manual to replace the cooling fan.

2. Set o4-03 = 0 [Fan.Oper Setting = 0 h] to reset the cooling

fan operation time.

Note:

• The drive detects this error if the heatsink temperature of the drive is more than L8-02.

• If the drive detects this error, the terminal assigned to H2-01, H2-02, and H2-03 = 4 [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-4CM Funct Selection =

Alarm] will be ON.

• Set the stopping method for this fault in L8-03 [Overheat Pre-Alarm Selection].

Code Name Causes Possible Solutions

oH2 External Overheat (H1-XX=7D)

An external device sent an oH2. 1. Find the external device that output the overheat alarm.

2. Remove the cause of the problem.

3. Clear the Overheat Alarm (oH2) [H1-xx = 7D] that was set to

MFDI terminals DI1 to DI8.

Note:

If the drive detects this error, the terminal assigned to H2-01, H2-02, and H2-03 = 4 [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-4CM Funct Selection =

Alarm] will be ON.

Code Name Causes Possible Solutions

oH3 Motor Overheat (PTC Input)

The thermistor wiring that detects motor

temperature is defective.

Correct wiring errors.

A fault occurred on the machine.

Example: The machine is locked.

Examine the machine and remove the cause of the fault

Loading...

Loading...