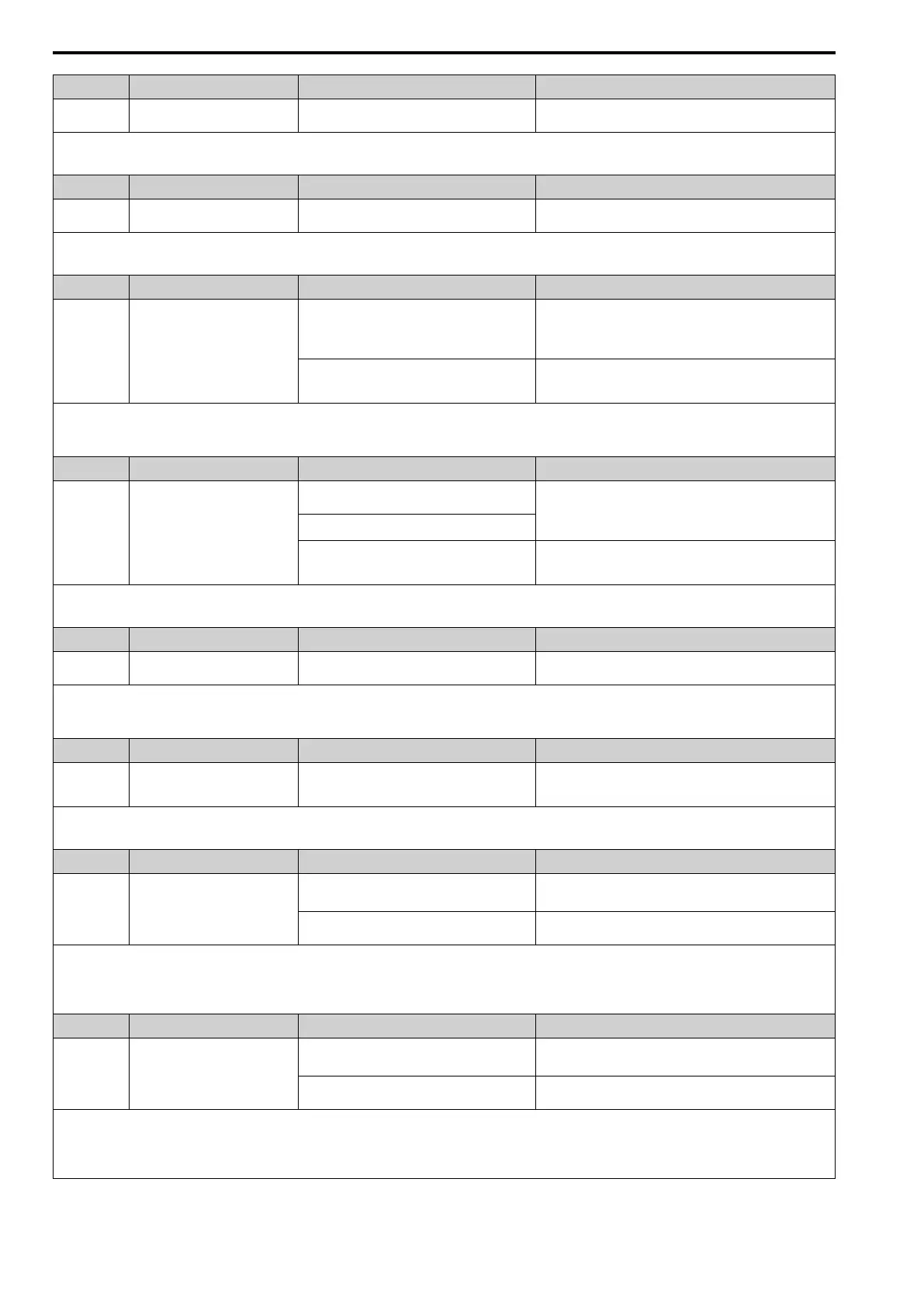

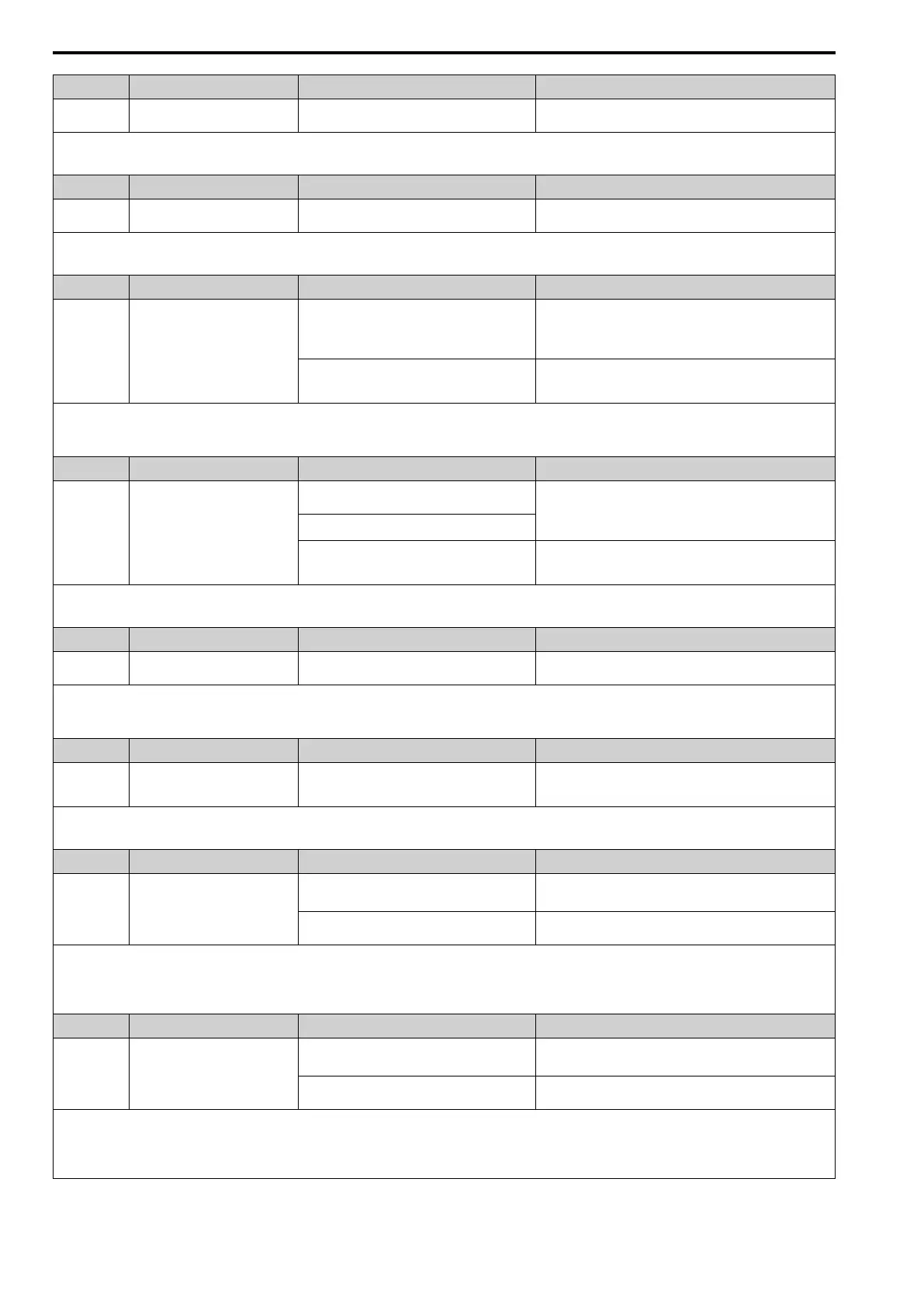

7.5 Minor Faults/Alarms

282 SIEPYEUOQ2A01A AC Drive Q2A Technical Manual

Code Name Causes Possible Solutions

rUn Motor Switch during Run

The drive received a Motor 2 Selection [H1-xx =

61] during run.

Make sure that the drive receives the Motor 2 Selection while the

drive is stopped.

Note:

If the drive detects this error, the terminal assigned to H2-01, H2-02, and H2-03 = 4 [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-4CM Funct Selection =

Alarm] will be ON.

Code Name Causes Possible Solutions

SE Modbus Test Mode Error

Modbus communications self-diagnostics [H1-xx =

7F] was done while the drive was running.

Stop the drive and do Modbus communications self-diagnostics.

Note:

If the drive detects this error, the terminal assigned to H2-01, H2-02, and H2-03 = 4 [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-4CM Funct Selection =

Alarm] will be ON.

Code Name Causes Possible Solutions

STo Safe Torque OFF

Safe Disable inputs H1-HC and H2-HC are open. • Make sure that the Safe Disable signal is input from an

external source to terminal H1-HC and H2-HC.

• When the Safe Disable function is not in use, connect

terminals H1-HC and H2-HC.

There is internal damage to the two Safe Disable

channels.

Replace the board or the drive. For information about replacing

the control board, contact the manufacturer or your nearest sales

representative.

Note:

• The drive will not output an alarm signal for this alarm.

• If the drive detects this error, the terminal assigned to H2-01, H2-02, H2-03 = E [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-4CM Funct Selection =

Safe Torque OFF] will be ON.

Code Name Causes Possible Solutions

SToF Safe Torque OFF Hardware

One of the two terminals H1-HC or H2-HC

received the Safe Disable input signal.

The Safe Disable input signal is wired incorrectly.

• Make sure that the Safe Disable signal is input from an

external source to terminal H1-HC and H2-HC.

• When the Safe Disable function is not in use, connect

terminals H1-HC and H2-HC.

There is internal damage to one Safe Disable

channel.

Replace the control board or the drive. For information about

replacing the control board, contact the manufacturer or your

nearest sales representative.

Note:

If the drive detects this error, the terminal assigned to H2-01, H2-02, and H2-03 = 4 [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-4CM Funct Selection =

Alarm] will be ON.

Code Name Causes Possible Solutions

TiM Keypad Time Not Set

There is a battery in the keypad, but the date and

time are not set.

Set the date and time with the keypad.

Note:

• o4-24 [bAT Detection Selection] enables and disables TiM detection.

• If the drive detects this error, the terminal assigned to H2-01, H2-02, and H2-03 = 4 [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-4CM Funct Selection =

Alarm] will be ON.

Code Name Causes Possible Solutions

TrPC IGBT Maintenance Time (90%)

The IGBT is at 90% of its expected performance

life.

Replace the IGBT or the drive. For information about replacing

the control board, contact the manufacturer or your nearest sales

representative.

Note:

If the drive detects this error, the terminal assigned to H2-01, H2-02, and H2-03 = 4 [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-4CM Funct Selection =

Alarm] will be ON.

Code Name Causes Possible Solutions

UL3 Undertorque Detection 1

A fault occurred on the machine.

Example: There is a broken pulley belt.

Examine the machine and remove the cause of the fault.

The parameters are incorrect for the load. Adjust L6-02 [Trq Det1 Level] and L6-03 [Trq Det1 Time]

settings.

Note:

• The drive detects this error if the drive output current is less than the level set in L6-02 for longer than L6-03.

• If the drive detects this error, the terminal assigned to H2-01, H2-02, and H2-03 = 4 [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-4CM Funct Selection =

Alarm] will be ON.

• If the drive detects this error, it will operate the motor as specified by the Stopping Method set in L6-51 [Trq Det1 Action] when L6-01 = 1 [Trq Det1 Select = Enabled].

Code Name Causes Possible Solutions

UL4 Undertorque Detection 2

A fault occurred on the machine.

Example: There is a broken pulley belt.

Examine the machine and remove the cause of the fault.

The parameters are incorrect for the load. Adjust L6-05 [Trq Det2 Level] and L6-06 [Trq Det2 Time]

settings.

Note:

• The drive detects this error if the drive output current is less than the level set in L6-05 for longer than L6-06.

• If the drive detects this error, the terminal assigned to H2-01, H2-02, and H2-03 = 4 [2NO-2CM Func Selection, 3NO-3CM Func Selection, and 4NO-4CM Funct Selection =

Alarm] will be ON.

• If the drive detects this error, it will operate the motor as specified by the Stopping Method set in L6-04 [Trq Det2 Select].

Loading...

Loading...