8.3 Maintenance

310 SIEPYEUOQ2A01A AC Drive Q2A Technical Manual

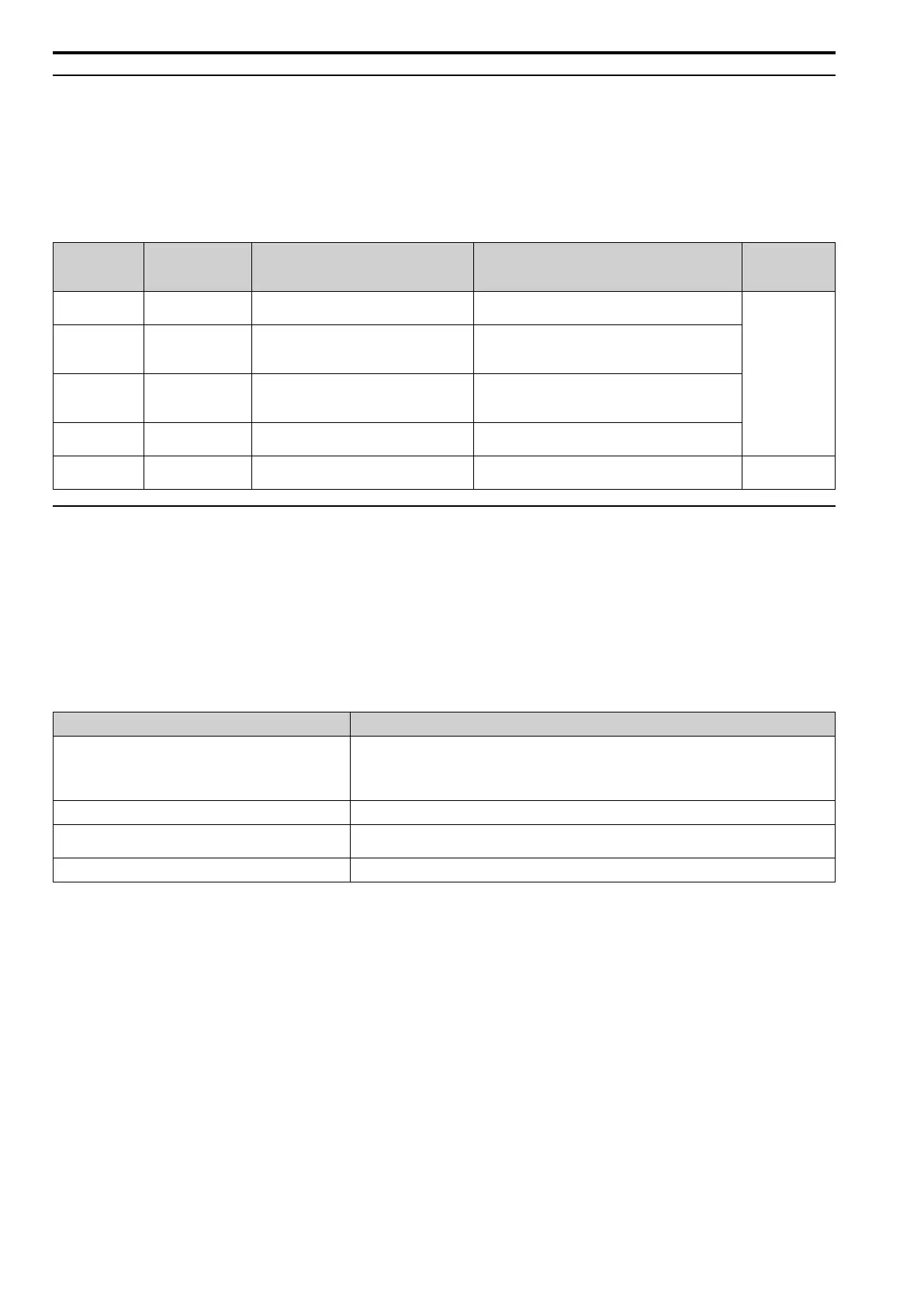

◆ Alarm Outputs for Maintenance Monitors

You can use H2-xx: MFDO Function Select to send a message that tells you when a specified component is near

the end of its performance life estimate. Set the applicable value to H2-xx as shown in the table below for your

component.

When the specified component is near the end of its performance life estimate, the MFDO terminals set for H2-xx

= 63 [Maintenance] will turn ON, and the keypad will show an alarm that identifies the component to replace.

Table 8.9 Maintenance Period Alarms

Display Alarm Name Cause Solution

MFDO

(Setting Value in

H2-xx)

LT-1

Cooling Fan

Maintenance Time

The cooling fan is at 90% of its performance life

estimate.

Replace the cooling fan, then set o4-03 = 0 [Fan.Oper

Setting = 0 h] to reset the cooling fan operation time.

63

LT-2

Capacitor

Maintenance Time

The main circuit and control circuit capacitors

are at 90% of their performance life estimate.

Replace the board or the drive.

Contact the manufacturer or your nearest sales

representative to replace the board.

LT-3

SoftChargeBypassRe

lay MainteTime

The soft charge bypass relay is at 90% of its

performance life estimate.

Replace the board or the drive.

Contact the manufacturer or your nearest sales

representative to replace the board.

LT-4

IGBT Maintenance

Time (50%)

The IGBTs are at 50% of their performance life

estimate.

Check the load, carrier frequency, and output frequency.

TrPC

IGBT Maintenance

Time (90%)

The IGBTs are at 90% of their performance life

estimate.

Replace the IGBTs or the drive.

4

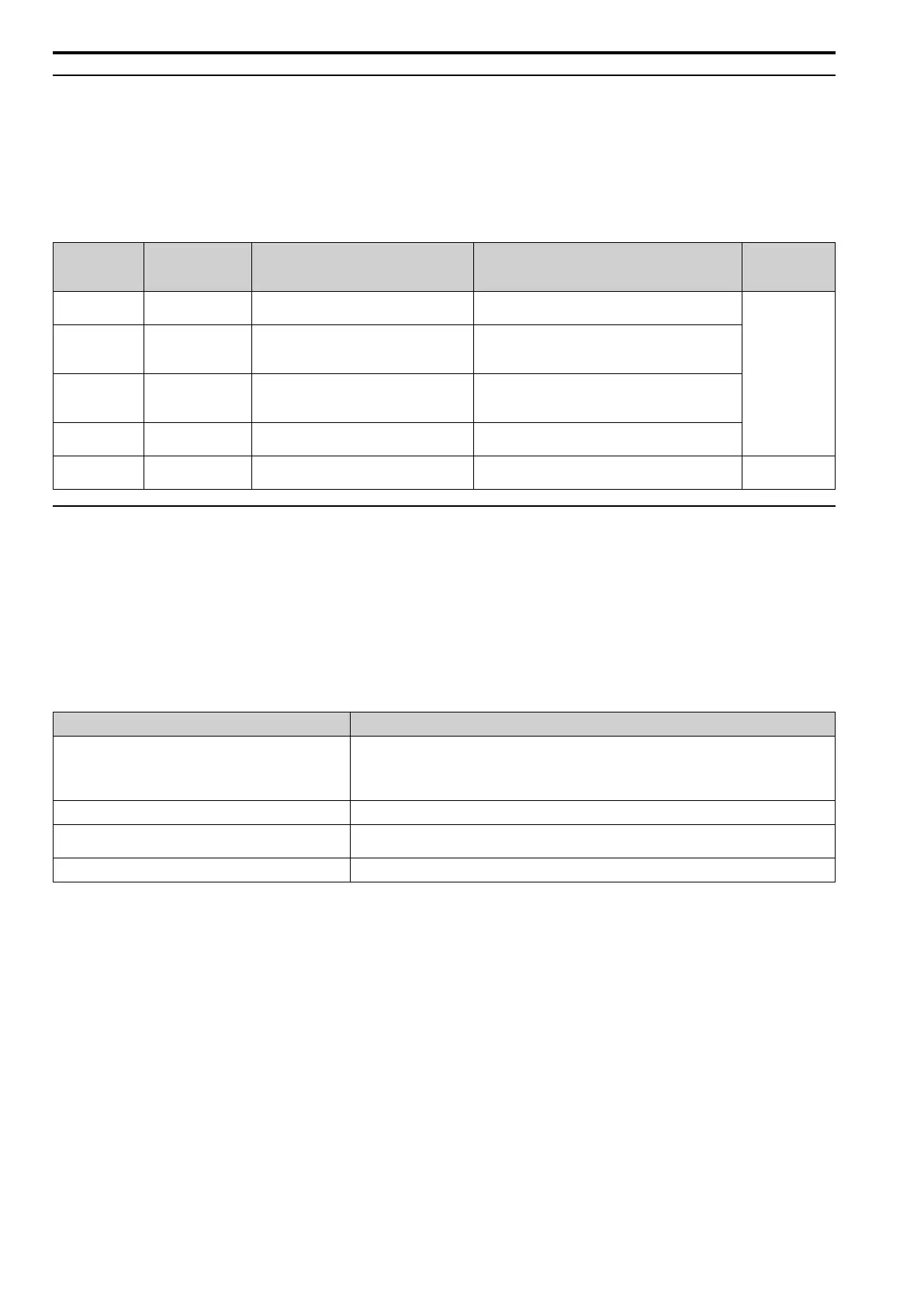

◆ Related Parameters

Replace the component, then set Maintenance Setting o4-03, o4-05, o4-07, and o4-09 = 0 to reset the

Maintenance Monitor. If these parameters are not reset after the corresponding parts have been replaced, the

Maintenance Monitor function will continue to count down the performance life from the value that was reached

with the old part. If the Maintenance Monitor is not reset, the drive will not have the correct value of the

performance life for the new component.

Note:

The drive installation environment has an effect on the maintenance period.

Table 8.10 Maintenance Setting Parameters

Parameter Function

o4-03 [Fan.Oper Setting] Sets the value from which to start the cumulative drive cooling fan operation time in 10-hour units.

Note:

When o4-03 = 30 has been set, the drive will count the operation time for the cooling fan from 300 hours

and U4-03 [Fan Oper.Time] will show 300 h.

o4-05 [Cap.Maint.Setting]

Sets the value from which to start the count for the main circuit capacitor maintenance period as a percentage.

o4-07 [PreChgRly Preset Maintenance Cnt] Sets as a percentage the value from which to start the count for the soft charge bypass relay maintenance

time.

o4-09 [IGBT Preset Maintenance Cnt] Sets the value from which to start the count for the IGBT maintenance period as a percentage.

Loading...

Loading...