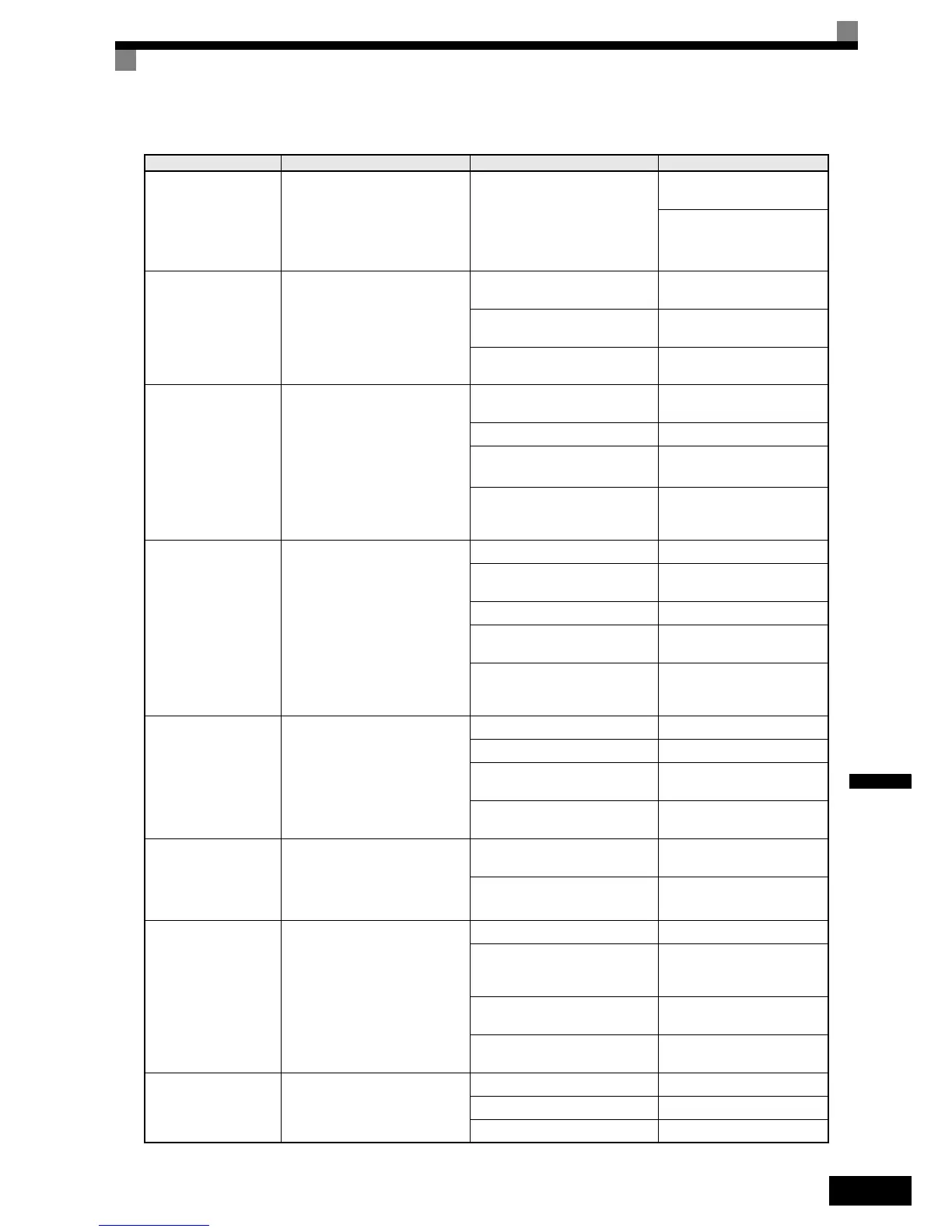

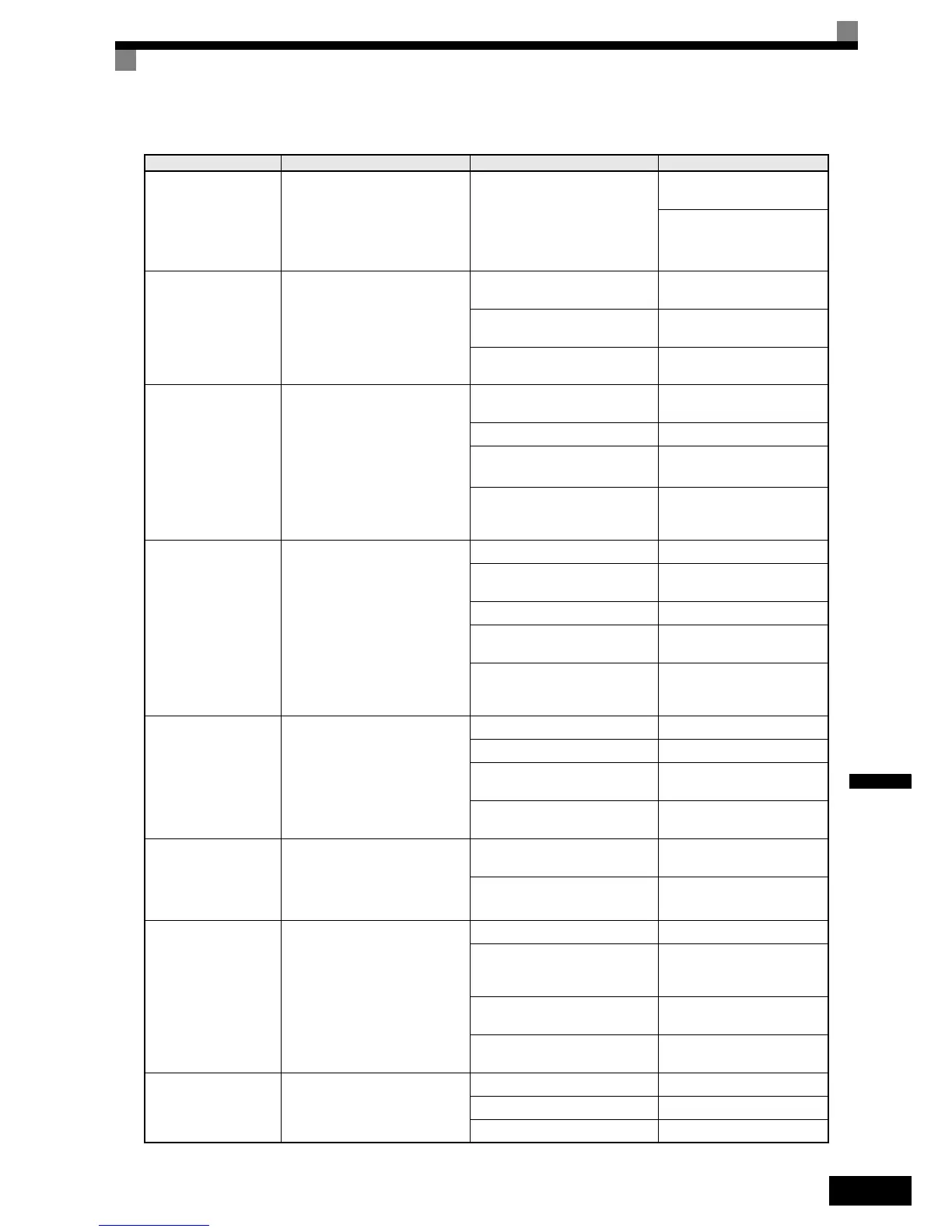

7-5

7

UL4

Undertorq Det 2

Undertorque Detection 2

The Inverter’s output current (V/f con-

trol) or the output torque (Vector con-

trol) fell below L6-05 for longer than

the time set in L6-06 and L6-04 is set to

7 or 8.

Motor was underloaded.

Ensure the values in L6-05 and L6-

06 are appropriate.

Check application/machine status

to eliminate fault.

OS

Overspeed Det

Motor Overspeed

Detected when F1-03 is set to 0, 1 or 2

and A1-02 is set to 3.

The motor speed feedback (U1-05)

exceeded the setting in F1-08 for a time

longer than the setting of F1-09.

Overshooting/Undershooting occurs.

Adjust the ASR settings in the C5

parameter group.

The reference was too high.

Check the reference circuit and ref-

erence gain.

The settings in F1-08 and F1-09 are not

appropriate.

Check the settings in F1-08 and F1-

09.

PGO

PG Open

PG Disconnection

Detected when F1-02 is set to 0, 1 or 2

and A1-02 is set to 3 or 6

Detected when no PG (encoder) pulses

are received for a time longer than the

setting of F1-14.

The PG wiring is broken.

Fix the broken/disconnected wir-

ing.

The PG is wired incorrectly. Fix the wiring.

Power is not supplied to the PG.

Supply power to the PG

properly.

Wrong brake control sequence. The

motor runs against the closed brake.

Check the sequence and if the brake

is opened when the inverter starts to

increase the speed.

DEV

Speed Deviation

Excessive Speed Deviation

Detected when F1-04 is set to 0, 1 or 2

and A1-02 is set to 3 or 6

The speed deviation is higher than the

setting of F1-10 for a time longer than

the setting of F1-11.

The load is too large. Reduce the load.

The acceleration time and deceleration

time are too short.

Lengthen the acceleration time and

deceleration time.

The load is locked. Check the mechanical system.

The settings of F1-10 and F1-11 are not

appropriate.

Check the settings of F1-10 and F1-

11.

Wrong brake control sequence. The

motor runs against the closed brake.

Check the sequence and if the brake

is opened when the inverter starts to

increase the speed.

DV3

Wrong rotation direction

Detected when the speed deviation is

higher than 30% and the torque refer-

ence and acceleration have opposite

signs.

PG wire broken Check the PG wiring

Incorrect PG wiring Correct the wiring

Wrong magnet position compensation

value (F1-22)

Verify the PG direction and execute

an encoder offset auto tuning

The load is too large

Reduce the load and check the

brake

DV4

Wrong rotation direction

Detected when F1-19 is not 0, the

speed reference and motor speed have

opposite signs and the detection thresh-

old set in F1-19 is exceeded.

The magnet position offset setting in

F1-22 is wrong

Verify the PG direction and execute

an encoder offset auto tuning

The load is too large

Reduce the load and check the

brake

DV6

Over Acceleration

An over acceleration of the car was

detected (A1-02 = 6 only)

The load is too large Reduce the load

Magnet position offset is wrong

Check the PG direction, check F1-

22 and perform an encoder offset

tuning.

Sheave diameter, gear ratio or roping

setting incorrect

Verify the settings of S3-13, S3-14

and S3-15.

Too short acceleration or deceleration

time.

Adjust the acceleration and deceler-

ation times.

SVE

Zero Servo Fault

Zero Servo Fault

The motor position moved during Zero

Servo Operation.

The torque limit is too small. Increase the torque limit.

The load torque is too large. Decrease the load torque.

- Check for signal noise.

Table 7.1 Resetable Faults

Display Meaning Probable Causes Corrective Actions

Loading...

Loading...