2-18

2

Control Circuit Terminal Functions

The functions of the control circuit terminals are shown in Table 2.9. Use the appropriate terminals for the cor-

rect purposes.

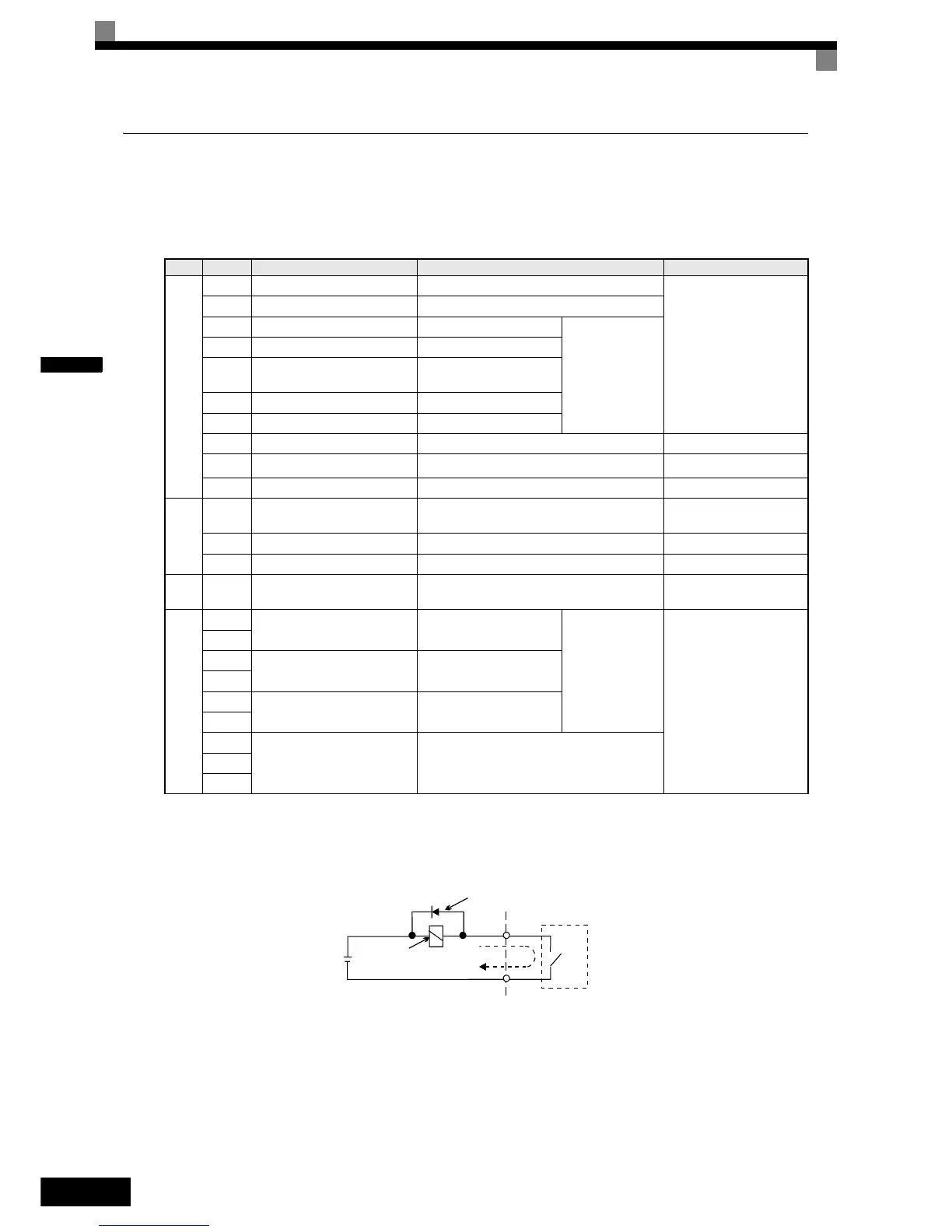

Table 2.9 Control Circuit Terminals with default settings

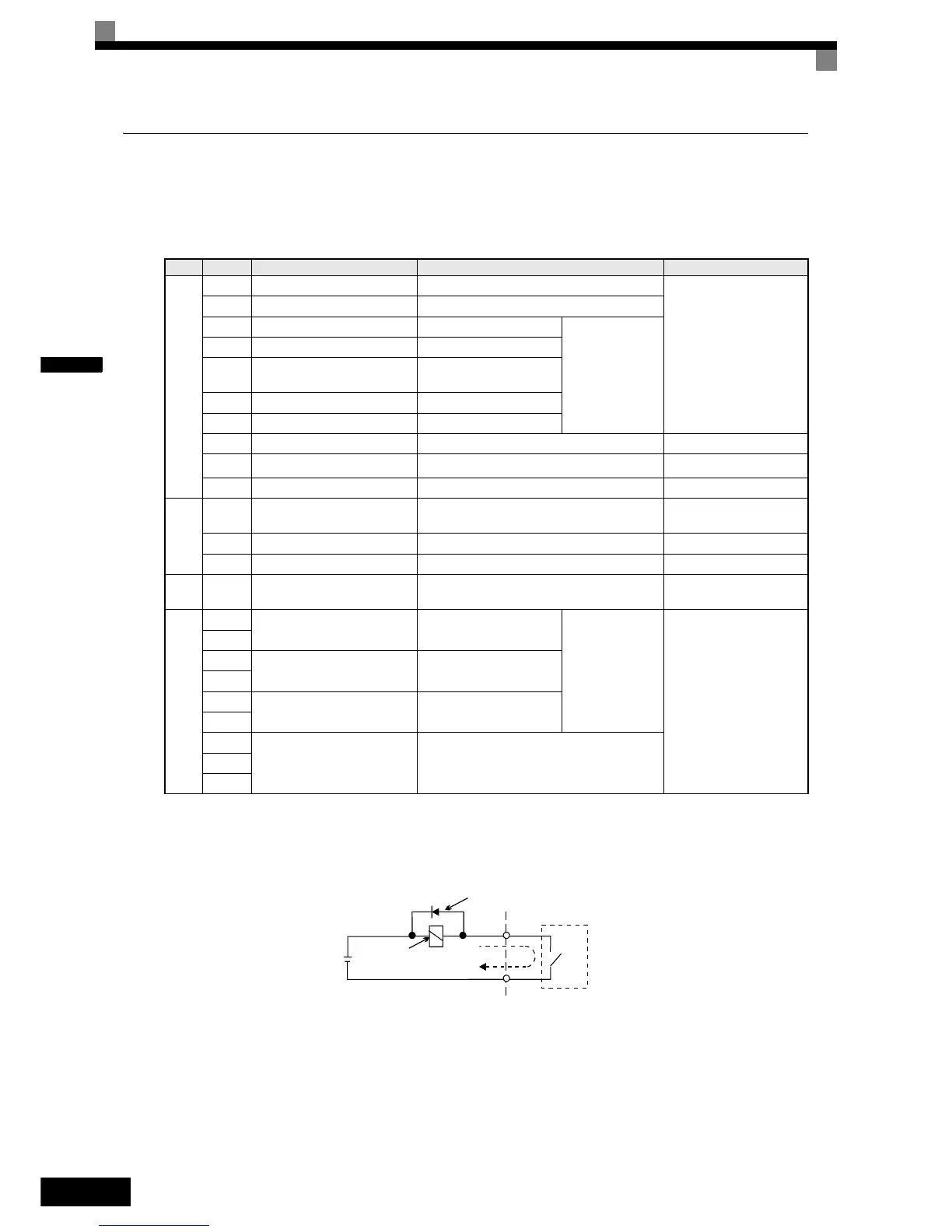

Fig 2.11 Flywheel Diode Connection

Type No. Signal Name Function Signal Level

Digi-

tal

input

signals

S1 Forward run/stop command Forward run when ON; stopped when OFF.

24 VDC, 8 mA

Photo-coupler

S2 Reverse run/stop command Reverse run when ON; stopped when OFF.

S3 Nominal speed Nominal speed when ON.

Functions are

selected by setting

H1-01 to H1-05.

S4 Inspection Run Inspection RUN when ON.

S5 Intermediate speed

Intermediate speed when

ON.

S6 Leveling speed Leveling speed when ON.

S7 Not used –

BB Hardware baseblock – –

BB1

*1

*1. This terminal is available on inverters with hardware SPEC B only. (page 1-4, Inverter Specifications describes how to find out the inverter

hardware version).

Hardware baseblock 1 – –

SC Digital input common – –

Ana-

log

input

signals

+V

15 V power supply

*2

*2. Do not use this power supply for supplying any external equipment.

15 V power supply for analog references

15 V

(Max. current: 20 mA)

A1 Frequency reference 0 to +10 V/100% 0 to +10 V(20 kΩ)

AC Analog reference neutral – –

E(G)

Shield wire, optional ground line

connection point

––

Digi-

tal

output

signals

M1

Brake command

(1NO contact)

Brake command when ON.

Multi-function con-

tact outputs

Relay contacts

Contact capacity:

1 A max. at 250 VAC

1 A max. at 30 VDC

*3

*3. When driving a reactive load, such as a relay coil with DC power supply, always insert a flywheel diode as shown in Fig 2.11.

M2

M3

Contactor Control

(1NO contact)

Contactor Control when ON

M4

M5

Inverter Ready

(1NO contact)

Inverter Ready when ON.

M6

MA

Fault output signal (SPDT)

(1 Change over contact)

Fault when CLOSED across MA and MC

Fault when OPEN across MB and MC

MB

MC

External power: 30

VDC max.

Coil

Flywheel diode

1 A max.

The rating of the flywheel diode must

be at least as high as the circuit volt-

age.

Loading...

Loading...