Fuel

System

CARBURETOR

(Does

not

Apply

to

Spec

G

and

Later)

All

carburetors have a fixed main jet. An optional fixed

main jet is available for altitude compensation above

5,000

feet.

The carburetor idle mixture was set for maximum

efficiency at the factory and should normally not be

disturbed.

If

adjustments seem necessary, first be sure

the ignition system is working properly and governor

sensitivity is properly adjusted.

The carburetor has a limited adjustment range between

stops of +1/8 turn. The screw should only be adjusted

within these limits; in

to

lean the mixture, out

to

richen.

-1

Ovetfightening the mixfureadjusfment

screw

wi//

cause carburetor damage.

Turn mixture adjustment screw

in

on/y

unfil

right

tension

can be felt.

If

replacing idle mixture screw, turn in until lightly

seated, then turn screw back

out

1-1 /4 turns for the

P216, P218, and P220 carburetors, and 1-1

/2

turns for

the P224 carburetor. Replace limiter cap with the plastic

stop approximately centered.

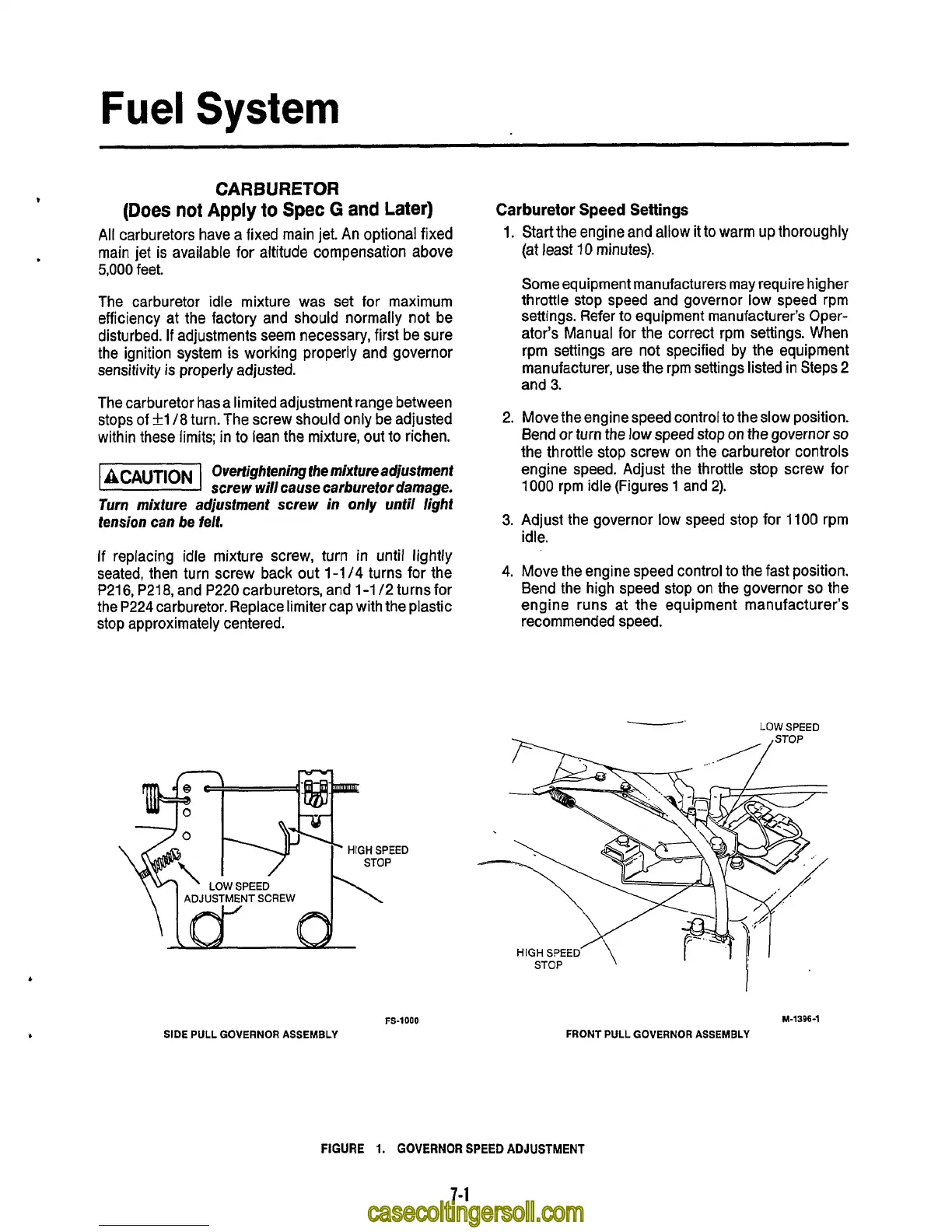

ADJUSTMENT

SCREW

FS-1000

SIDE PULL GOVERNOR ASSEMBLY

Carburetor

Speed

Settings

(at

least

10

minutes).

1.

Start the engine and allow it to warm up thoroughly

Some equipment manufacturers may require higher

throttle stop speed and governor

low

speed rpm

settings. Refer

to

equipment manufacturer’s Oper-

ator’s Manual for the correct rpm settings. When

rpm settings are not specified by the equipment

manufacturer, use the rpm settings listed in Steps

2

and

3.

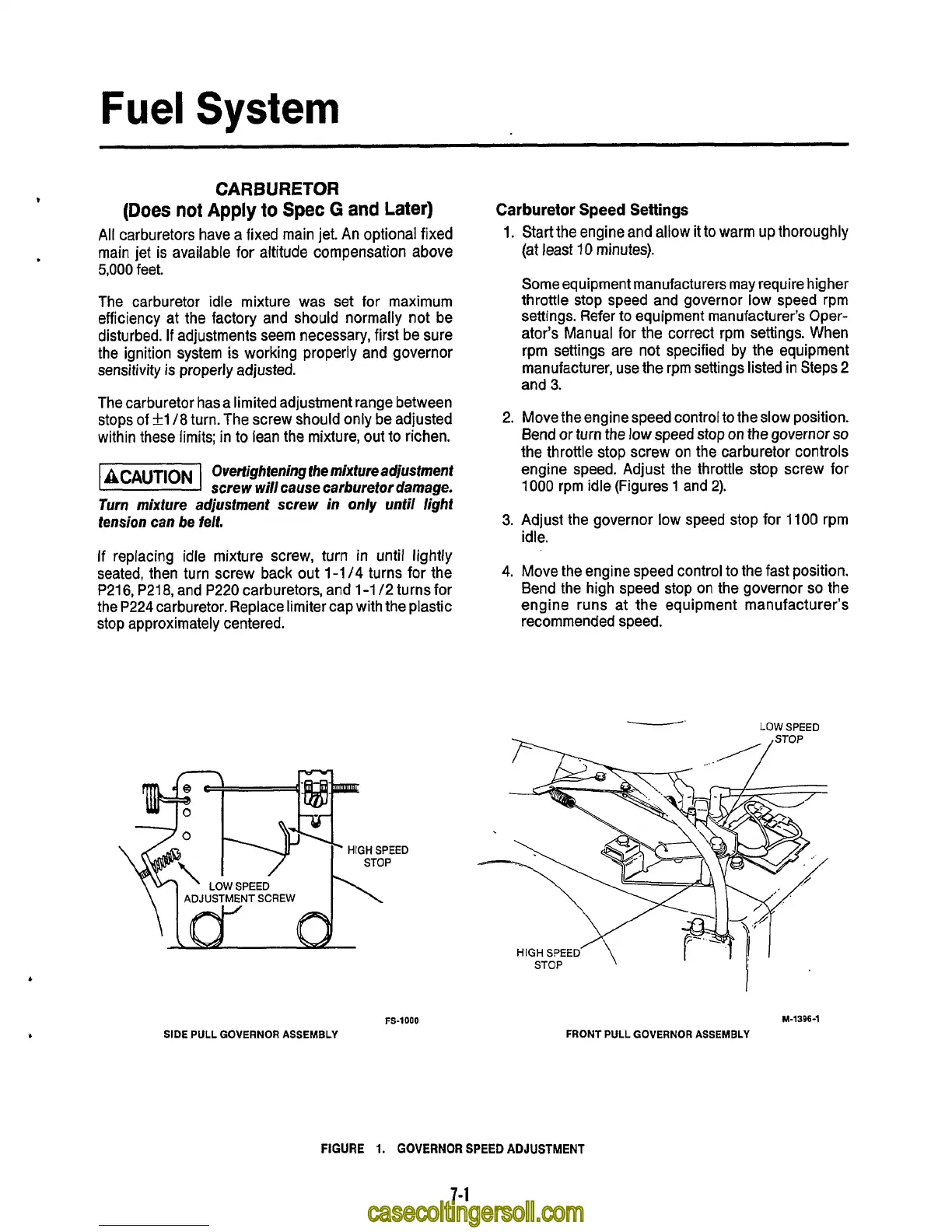

2.

Move the engine speed control

to

the slow position.

Bend or turn the low speed

stop

on the governor

so

the

throttle stop screw

on

the carburetor controls

engine speed. Adjust the throttle stop screw for

1000

rpm idle (Figures

1

and 2).

3.

Adjust the governor low speed stop for 1100 rpm

idle.

4.

Move the engine speed control to the fast position.

Bend the high speed stop

on

the governor

so

the

engine runs at the equipment manufacturer’s

recommended speed.

LOW

SPEED

-

\

STOP

M-13964

FRONT

PULL

GOVERNOR ASSEMBLY

FIGURE

1.

GOVERNOR SPEED ADJUSTMENT

7-1

Loading...

Loading...