jFGF3

ELEMENT

iR

ELEMENT

A-.

WRAPPER

<*:

-

COVER

\---

AIR

CLEANER

ELEMENT

/yl-f

i

AIR

PLATE

DEFLECTOR

I

AIR

CLEANER

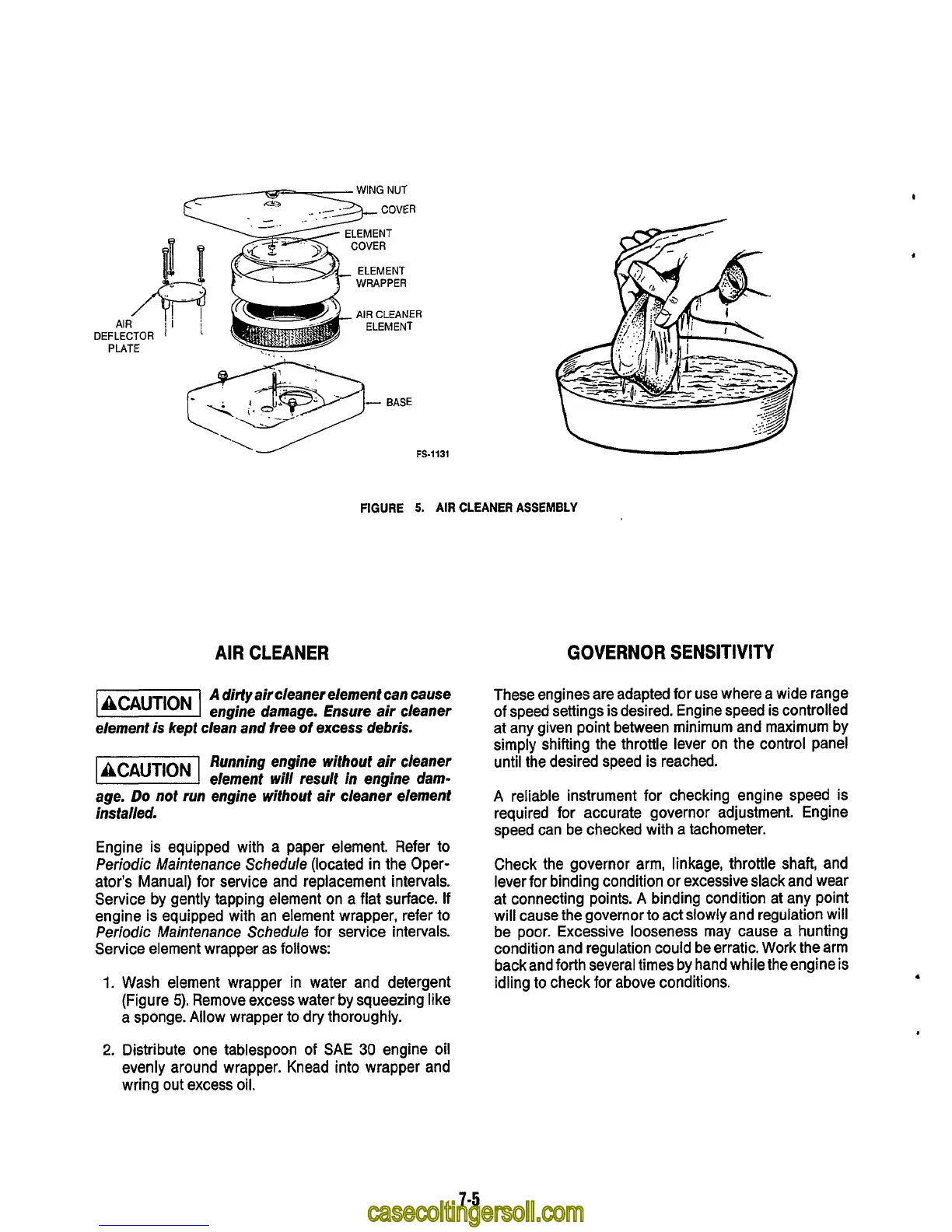

FIGURE

5.

AIR

CLEANER

ASSEMBLY

A

dirty air cleaner element can cause

engine damage. Ensure air cleaner

Running engine wifhout air cleaner

element will result in engine dam-

age.

Do

not run engine without air cleaner element

installed.

element

is

kept clean and free of excess debris.

Engine is equipped with a paper element. Refer to

Periodic Maintenance Schedule (located in the Oper-

ator’s Manual) for service and replacement intervals.

Service by gently tapping element on a flat surface. If

engine is equipped with an element wrapper, refer

to

Periodic Maintenance Schedule for service intervals.

Service element wrapper as follows:

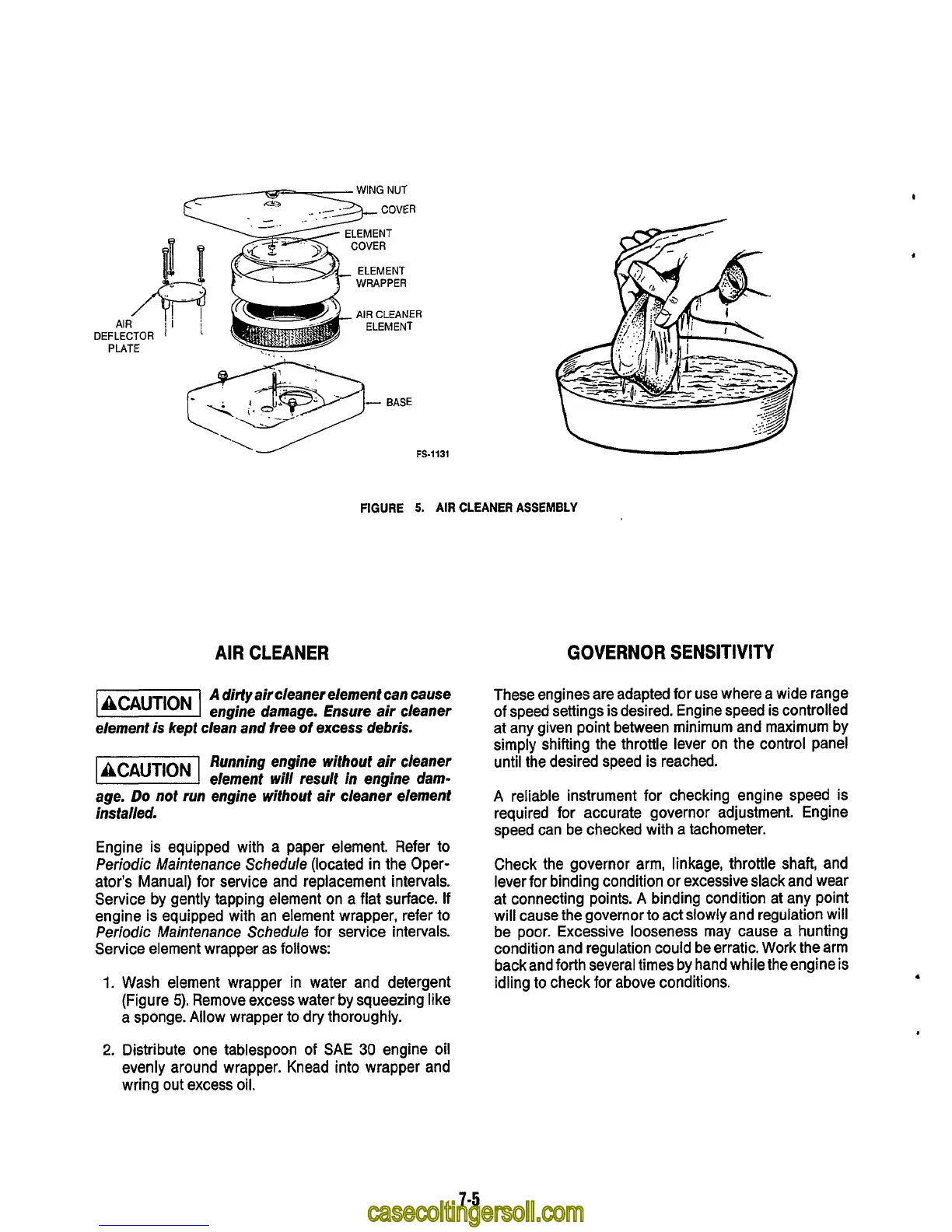

1.

Wash element wrapper in water and detergent

(Figure

5).

Remove excess water by squeezing like

a sponge. Allow wrapper

to

dry thoroughly.

2.

Distribute one tablespoon

of

SAE

30

engine oil

evenly around wrapper. Knead into wrapper and

wring out excess oil.

GOVERNOR SENSITIVITY

These engines are adapted for use where a wide range

of speed settings is desired. Engine speed is controlled

at any given point between minimum and maximum by

simply shifting the throttle lever on the control panel

until the desired speed is reached.

A reliable instrument for checking engine speed is

required for accurate governor adjustment. Engine

speed can be checked with a tachometer.

Check the governor arm, linkage, throttle shaft, and

lever for binding condition or excessive slack and wear

at connecting points.

A

binding condition at any point

will cause the governor to act slowly and regulation will

be poor. Excessive looseness may cause a hunting

condition and regulation could be erratic. Work the arm

back and forth several times by hand while the engine is

idling to check for above conditions.

7-5

Loading...

Loading...