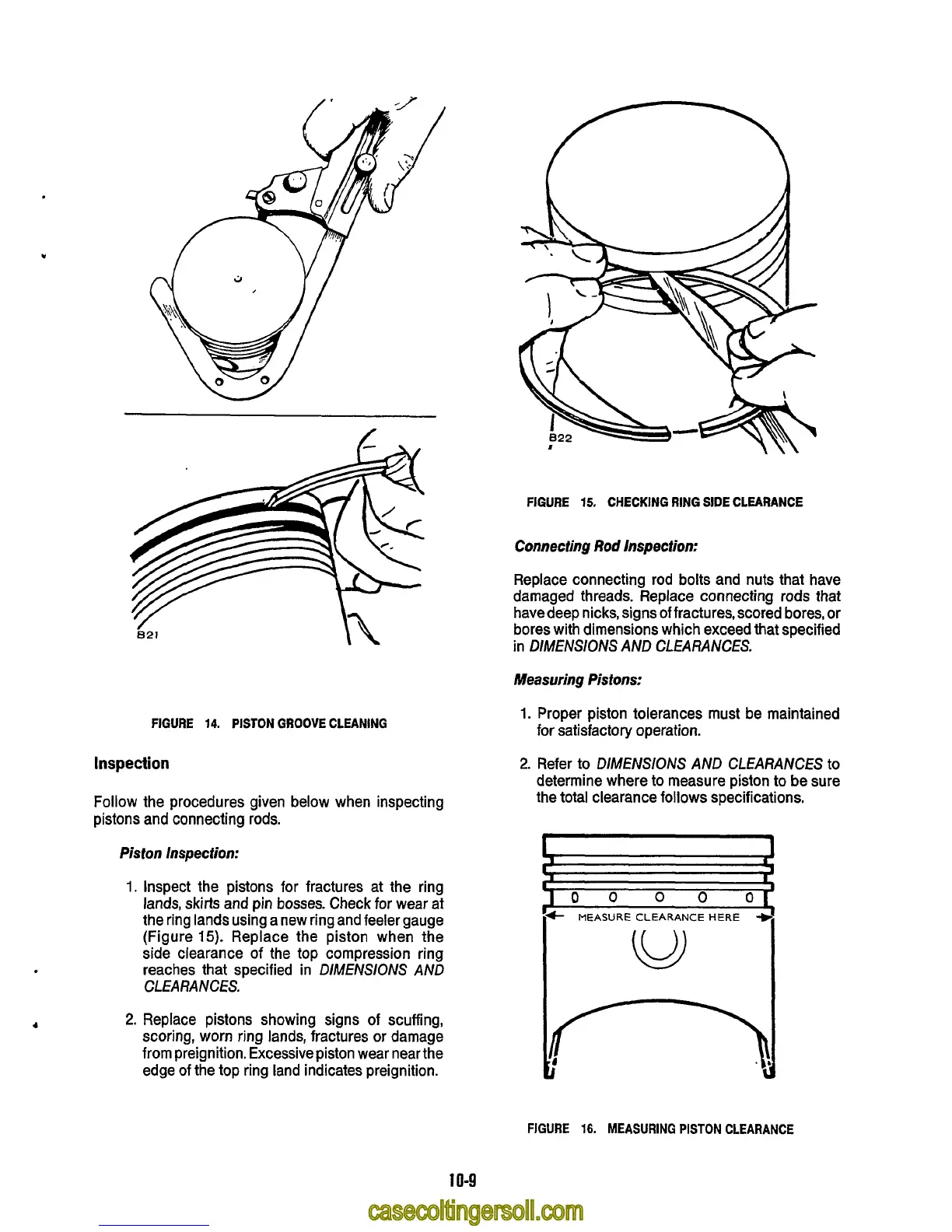

821

FIGURE

14.

PISTON GROOVE CLEANING

Inspection

Follow the procedures given below when inspecting

pistons and connecting rods.

Piston Inspection:

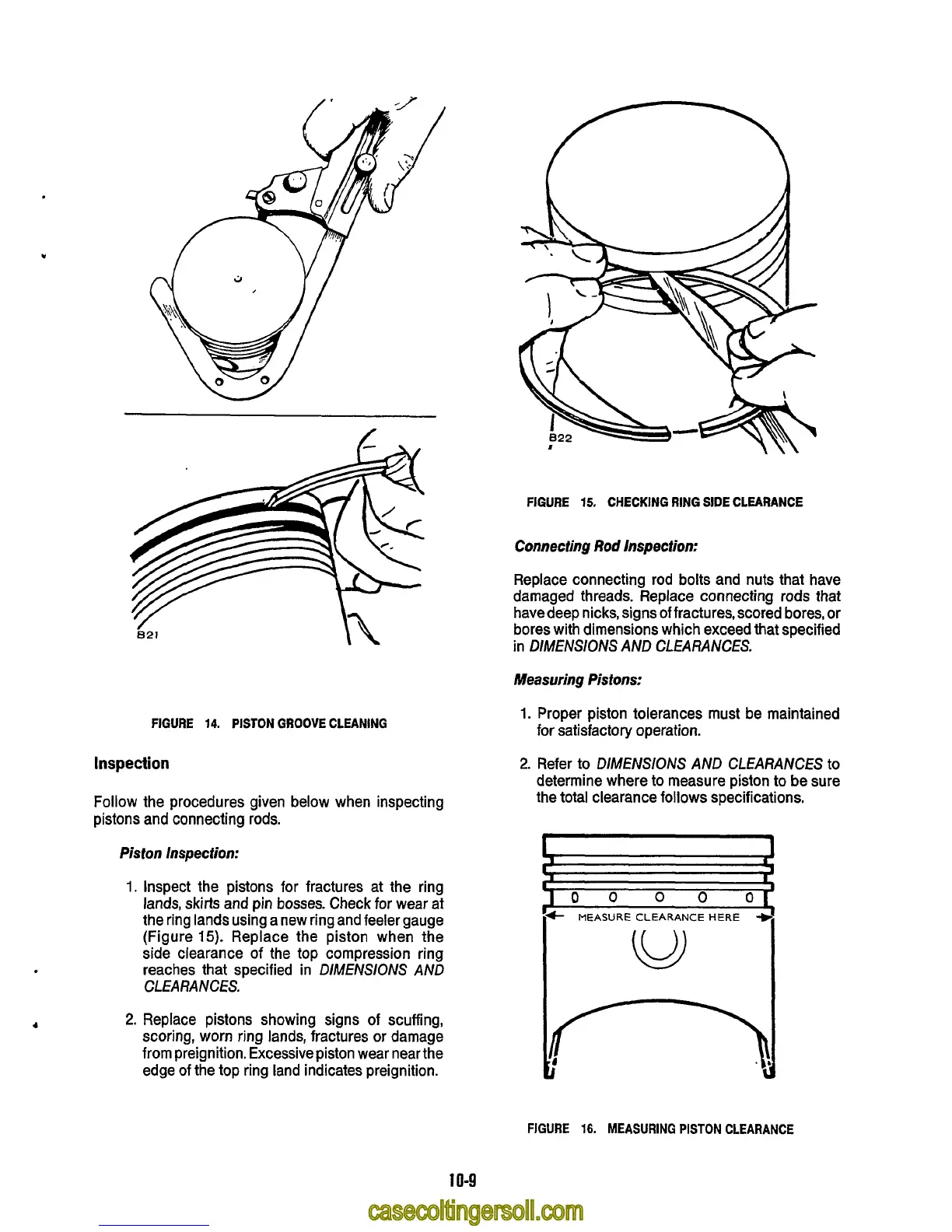

1.

Inspect the pistons for fractures at the ring

lands, skirts and pin bosses. Check for wear at

the ring lands using a new ring and feeler gauge

(Figure

15).

Replace the piston when the

side clearance

of

the top compression ring

reaches that specified in

DIMENSIONS AND

CLEARANCES.

2.

Replace pistons showing signs

of

scuffing,

scoring, worn ring lands, fractures or damage

from preignition. Excessive piston wear near the

edge of the top ring land indicates preignition.

FIGURE

15.

CHECKING RING SIDE CLEARANCE

Connecting

Rod

Inspection:

Replace connecting rod bolts and nuts that have

damaged threads. Replace connecting rods that

have deep nicks, signs of fractures, scored bores, or

bores with dimensions which exceed that specified

in

DIMENSIONS AND CLEARANCES.

Measuring Pistons:

1.

Proper piston tolerances must be maintained

for

satisfactory operation.

2.

Refer to

DIMENSIONS AND CLEARANCES

to

determine where to measure piston

to

be sure

the total clearance follows specifications.

s

I

I

MEASURE CLEARANCE

HERE

-d!

10

0

0

0

01

FIGURE

16.

MEASURING PISTON CLEARANCE

10-9

Loading...

Loading...