Valve Spring:

Check valve springs for cracks, worn

ends, distortion, and tension. If spring ends are worn,

check valve spring retainer for wear. Check for spring

distortion by placing spring on a flat surface next to a

square. Measure height of spring and rotate it against

square edge to measure distortion. If distortion exceeds

0.06

inch

(1.5

mm) replace spring. Check spring tension

at the installed height for both thevalve open and closed

position using an accurate valve spring tester. Replace

any valve spring that is weak, cracked, worn, or distorted.

Valve

RofafomThe

P216, P218, and P220 engines use

free-rotating intake and exhaust valves. While in the

open position, the valves must rotate freely.

The P224 engine uses positive type valve rotators on the

exhaust valves. When functioning properly, the valves

are rotated

a

fraction of a turn each time they open.

While in the open position, the valves must rotate freely.

There is no easy way to determine if a valve rotator is

good or bad. Onan recommends that valve rotators be

replaced at each major overhaul or

if

a build up of

carbon is noted on valve face and valve seat.

Valve Seats:

Inspect valve seat inserts.

If

seats are

loose, cracked or severely pitted, new ones must be

installed. Remove valve seat inserts using a valve seat

removal tool.

If

valve seat insert bores in cylinder block

are damaged or worn

so

that a press fit cannot be

obtained when installing new standard size valve seat

inserts, the bores must be machined for an oversize

seat.

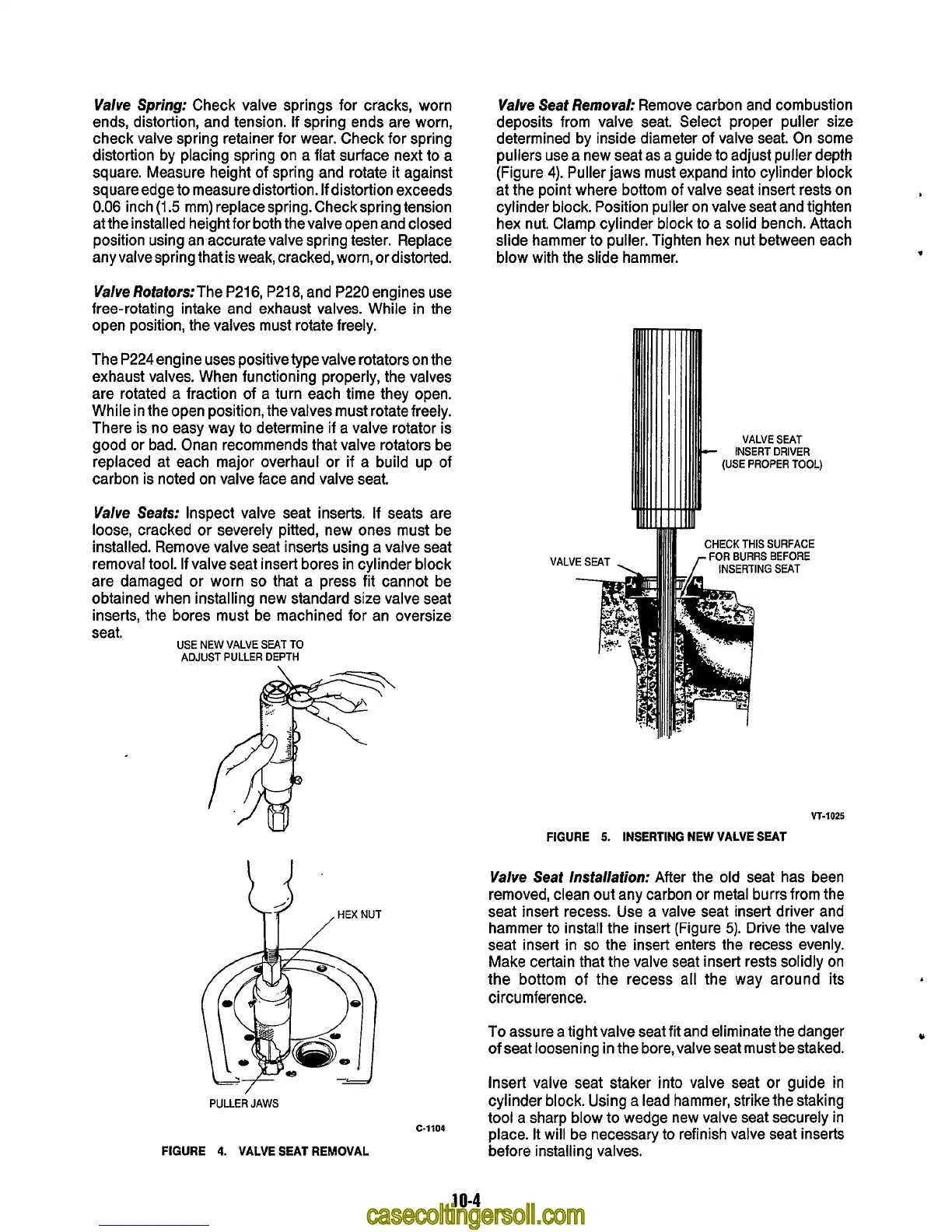

USE

NEW

VALVE

SEAT

TO

ADJUST

PULLER

DEPTH

PULLER

JAWS

FIGURE

4.

VALVE

SEAT

REMOVAL

Valve Seat Removal:

Remove carbon and combustion

deposits from valve seat. Select proper puller size

determined by inside diameter of valve seat. On some

pullers use a new seat as a guide to adjust puller depth

(Figure

4).

Puller jaws must expand into cylinder block

at the point where bottom

of

valve seat insert rests on

cylinder block. Position puller on valve seat and tighten

hex nut. Clamp cylinder block to a solid bench. Attach

slide hammer to puller. Tighten hex nut between each

blow with the slide hammer.

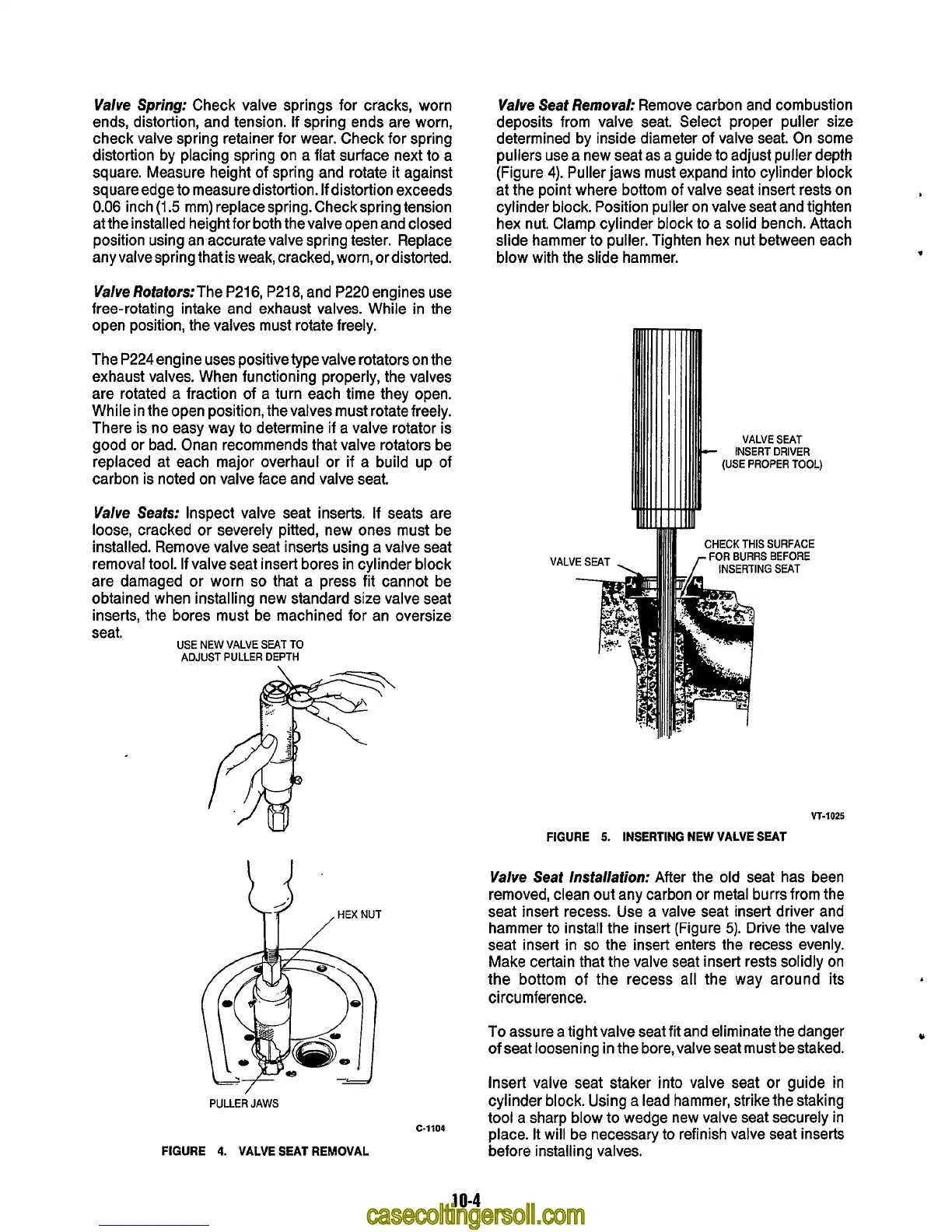

VALVE SEAT

INSERT

DRIVER

(USE

PROPER

TOOL)

CHECK

THIS

SURFACE

FOR

BURRS

BEFORE

f

INSERTING

SEAT

M-1025

FIGURE

5.

INSERTING

NEW

VALVE

SEAT

Valve Seat Installation:

After the old seat has been

removed, clean

out

any carbon or metal burrs from the

seat insert recess. Use a valve seat insert driver and

hammer to install the insert (Figure

5).

Drive the valve

seat insert in

so

the insert enters the recess evenly.

Make certain that the valve seat insert rests solidly on

the bottom

of

the recess all the way around

its

circumference.

To assure a tight valve seat

fit

and eliminate the danger

of seat loosening in the bore,valve seat must be staked.

Insert valve seat staker into valve seat or guide

in

cylinder block. Using

a

lead hammer, strike the staking

tool a sharp blow to wedge new valve seat securely in

place.

It

will be necessary to refinish valve seat inserts

before installing valves.

C-1104

Y

10-4

Loading...

Loading...