Tappet Adjustment

The engine is equipped with adjustable valve tappets.

The valve tappet clearance should be checked and

adjusted as specified in the Periodic Maintenance

Schedule (located in the Operator's Manual). Adjust the

valve clearance only when engine is at ambient temper-

ature. Proceed as follows:

1. Remove ignition key to prevent accidental starting.

2. Remove all parts necessary to gain access to valve

tappets.

3.

Remove spark plugs to ease the task of turning the

engine over by hand.

4. Place a socket wrench on the flywheel capscrew

and rotate the crankshaft in a clockwise direction

until the left intake valve (viewed from flywheel end)

opens and closes. Continue turning the crankshaft

until theTC markon the flywheel is lined up with the

TC mark on the gear cover. This should place the

left piston

(#I)

at the top

of

its compression stroke.

Verify that the left intake and exhaust valves are

closed and there is no pressure on the valve lifters.

5.

The correct feeler gauge for the valve adjustment

(see

SPE

ClFlCATI0NS)should pass freely between

valve cap (P216, P218, P220) or valve stem (P224)

and tappet; a 0.002 inch

(0.05

mm) thicker gauge

should not (Figure 1).

6. To correct valve clearance, use a 7/16 inch open

end wrench

to

turn theadjusting screw toobtain the

correct clearance. The screw is self-locking and

will stay where it is set.

A

9/16 inch (14 mm) open

end wrench is required to hold the tappet while

turning the adjusting screw.

7.

To

adjust valves on the right hand cylinder, turn

engine one complete revolution and again line up

mark on the flywheel and the TC mark on the gear

cover. Then follow adjustment procedure given for

left hand cylinder.

8.

Replace all parts removed in Step 2. Tighten all

screws securely. Torque manifold bolts to specified

torque.

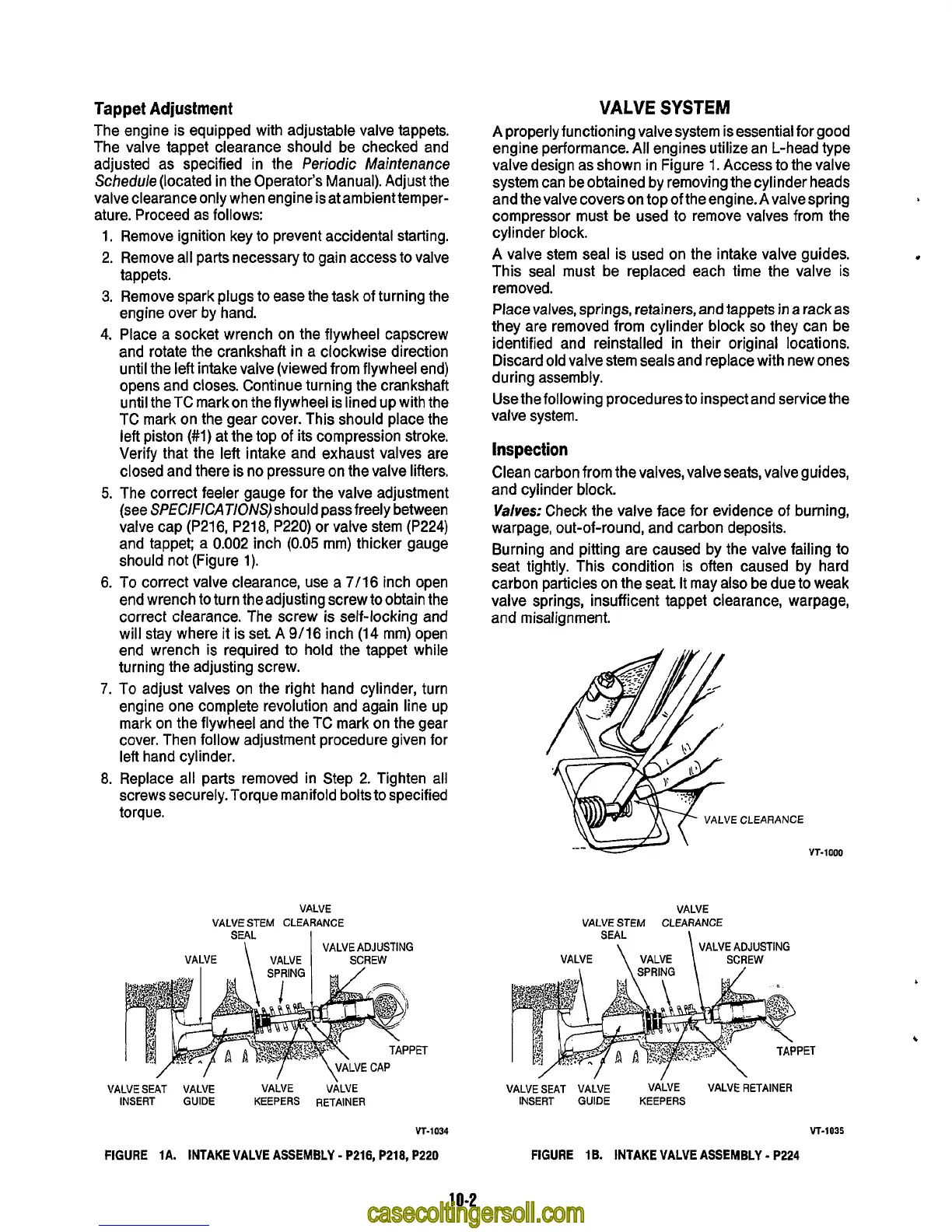

VALVE

VALVE STEM CLEARANCE

SEAL

I

VALVE ADJUSTING

VALVE

\

VALVE SCREW

VALVE

SYSTEM

A

properly functioning valvesystem is essential for good

engine performance.

All

engines utilize an L-head type

valve design as shown in Figure

1.

Access to the valve

system can be obtained by removing the cylinder heads

and thevalve coverson

topoftheengine.Avalvespring

compressor must be used to remove valves from the

cy1 inder block.

A valve stem seal is used on the intake valve guides.

This seal must be replaced each time the valve is

removed.

Place valves, springs, retainers, and tappets

in

a rack

as

they are removed from cylinder block

so

they can be

identified and reinstalled in their original locations.

Discard old valve stem seals and replace with new ones

during assembly.

Use the following procedures to inspect and service the

valve system.

Inspection

Clean carbon from thevalves, valve seats, valve guides,

and cylinder block.

Valves:

Check the valve face for evidence of burning,

warpage, out-of-round, and carbon deposits.

Burning and pitting are caused by the valve failing to

seat tightly. This condition

is

often caused by hard

carbon particles on the seat It may also be due to weak

valve springs, insufficent tappet clearance, warpage,

and misalignment.

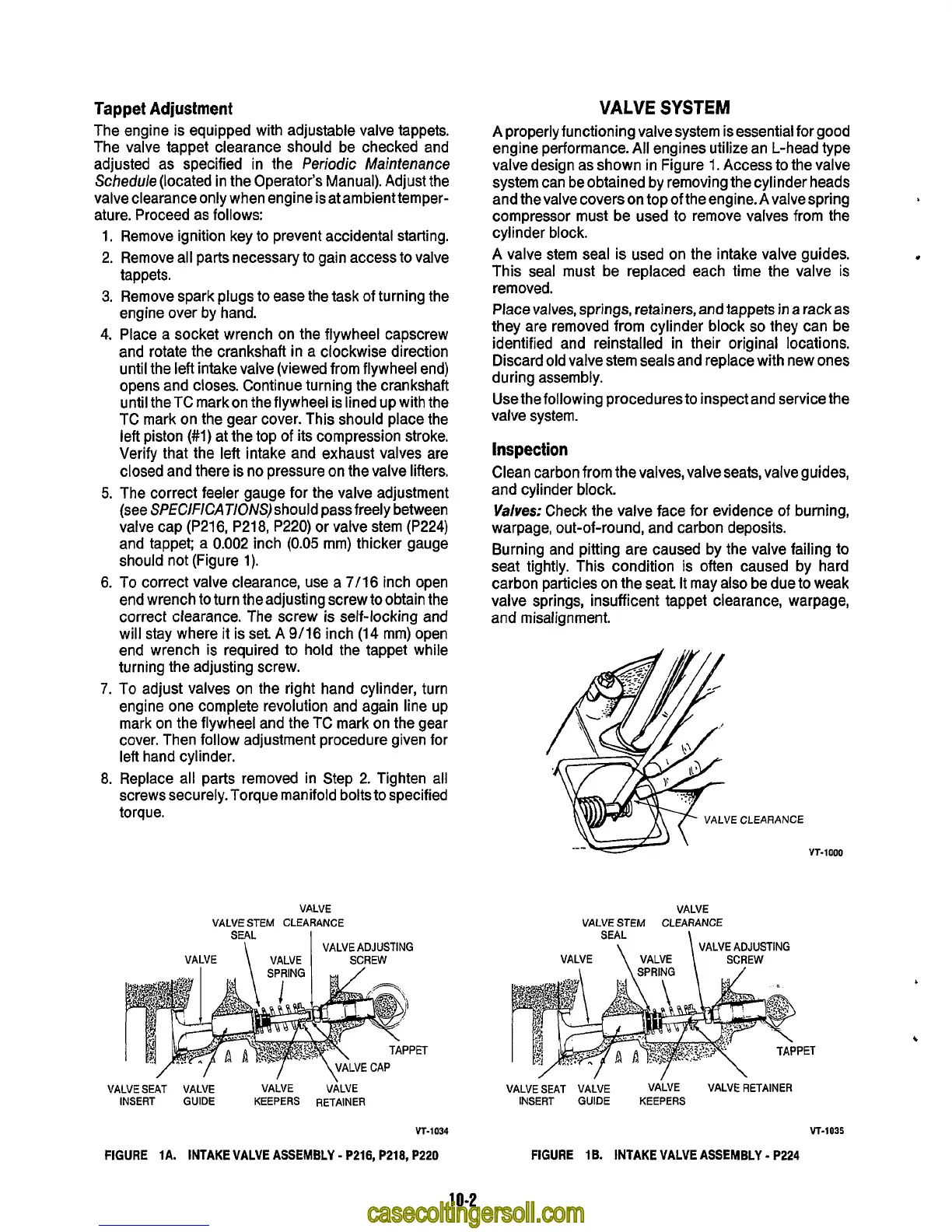

VALVE

VALVE STEM CLEARANCE

SEAL

\

\

VALVE

ADJUSTING

PET

VALVE SEAT VALVE

VALVE

VALVE

INSERT GUIDE KEEPERS RETAINER

VALVE SEAT VALVE VALVE

VALVE

RETAINER

INSERT GUIDE KEEPERS

c

VT-1034

FIGURE 1A. INTAKE VALVE ASSEMBLY

-

P216, P218, P220

WIT-1035

FIGURE 1B. INTAKE VALVE ASSEMBLY

-

P224

10-2

Loading...

Loading...