3 Operational Maintenance

3-4 AS3690 Operator Manual August 2010

Cleaning the System

When properly maintained, the AS-Series will continue to operate efficiently and

smoothly. However, over time, dust and dirt buildup can degrade the performance,

resulting in problems such as skewing, double feeds, document hesitation and

damage. The conveyor, stacker assembly, feed assembly (feed belts, idler pulleys,

pre-feed tire, retard pad) and the CIS (contact image sensor) require regular cleaning.

Regular and scheduled maintenance will ensure that the AS-Series continues to

function properly, with minimum downtime and maximum efficiency. This

maintenance procedure consists of debris/dust removal and general cleaning.

Conveyor and stacker assemblies

1 Stop all jobs and ensure that all motors are stopped.

2 Check the stacker cover once a shift. The stacker cover should be opened and

cleared of paper debris, dust, envelope flaps, etc.

NOTE: The cover needs to be closed before scanning can begin again.

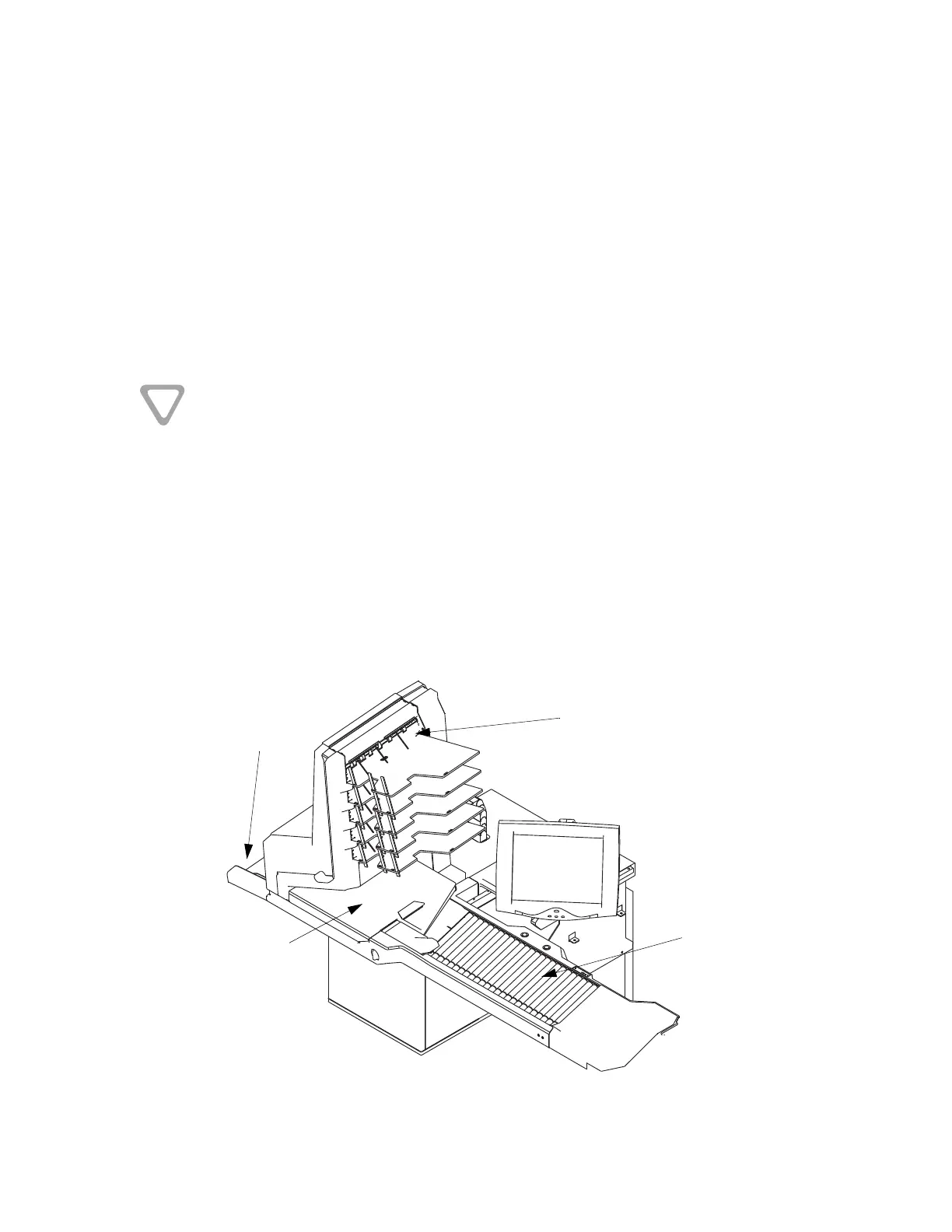

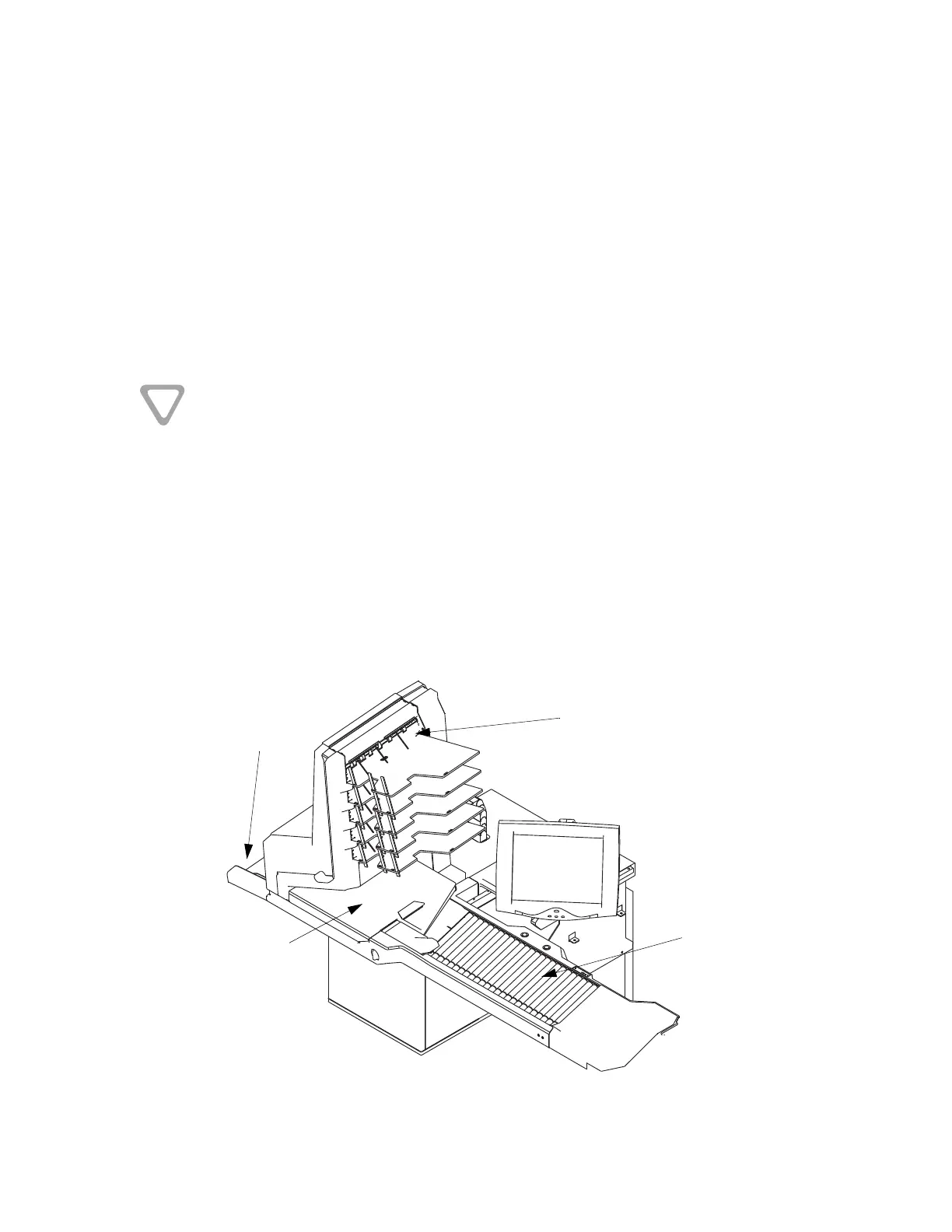

3 Vacuum dust and debris from the conveyor rollers and the stacker assembly (see

Figure 26).

FIGURE 26: Conveyor and Stacker Assembly

Be careful when working with cleaners. A cleaner-soaked cloth or similar material should never

be used to clean moving objects. For example, do not clean belts or rollers when the motors are

running. The use of a cloth or a similar material on moving mechanisms can result in severe

personal injury. If a belt, roller, pulley, or a similar part needs to be cleaned, hand-crank it during

cleaning or clean it while stationary.

Reject

Bin

Transport

Door

Stacker

Conveyor

Loading...

Loading...