9-44 Function Parameters

AC10 Inverter

F812 Pre-exciting time

Setting range: 0.000~30.00S

0.30S

F813 Rotary speed loop KP1

Setting range:

0.01~20.00

Subject to inverter

model

F814 Rotary speed loop KI1

Setting range:

0.01~2.00

Subject to inverter

model

F815 Rotary speed loop KP2

Setting range:

0.01~20.00

Subject to inverter

model

F816 Rotary speed loop KI2

Setting range:

0.01~2.00

Subject to inverter

model

F817 PID switching frequency 1 Setting range: 0~F111 5.00

F818 PID switching frequency 2 Setting range: F817~F111 50.00

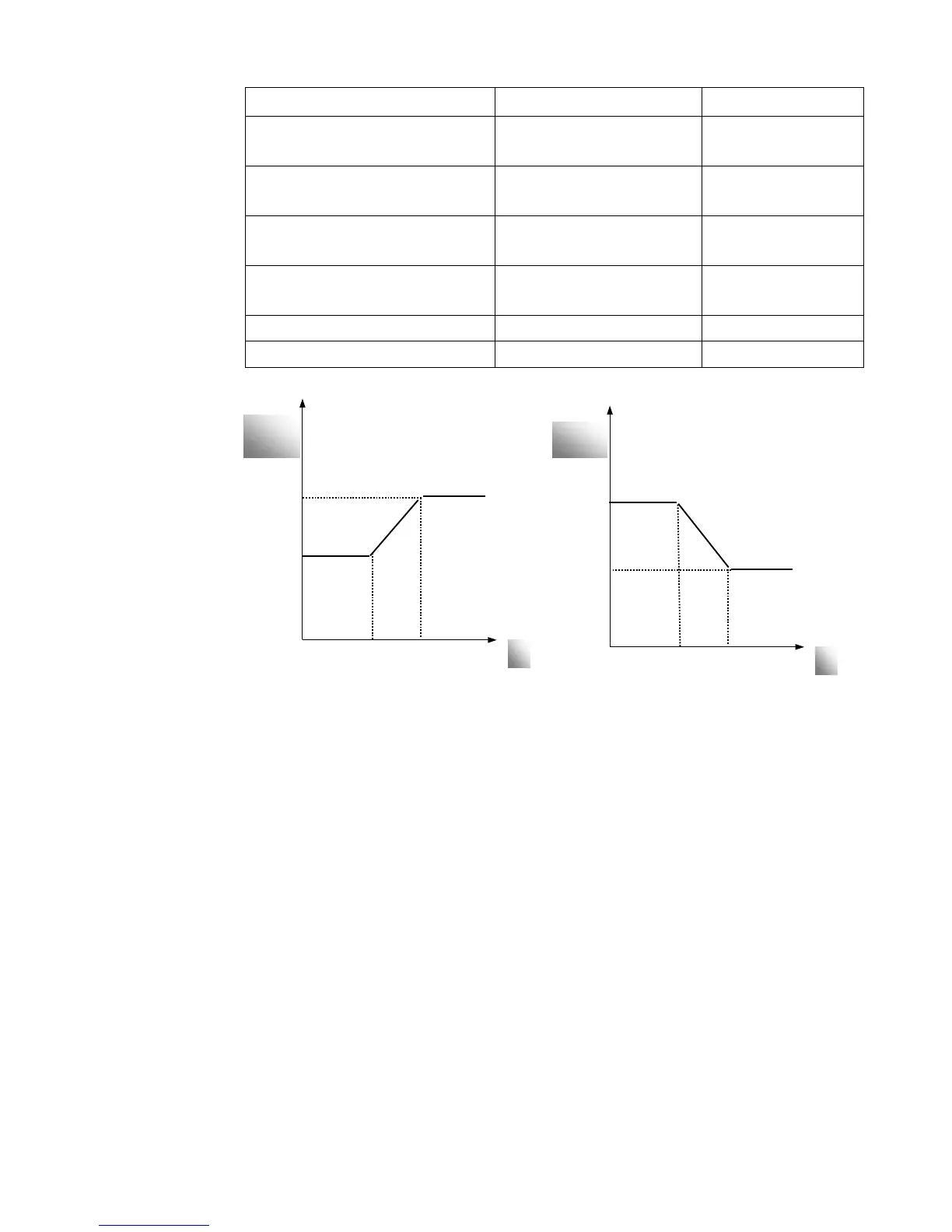

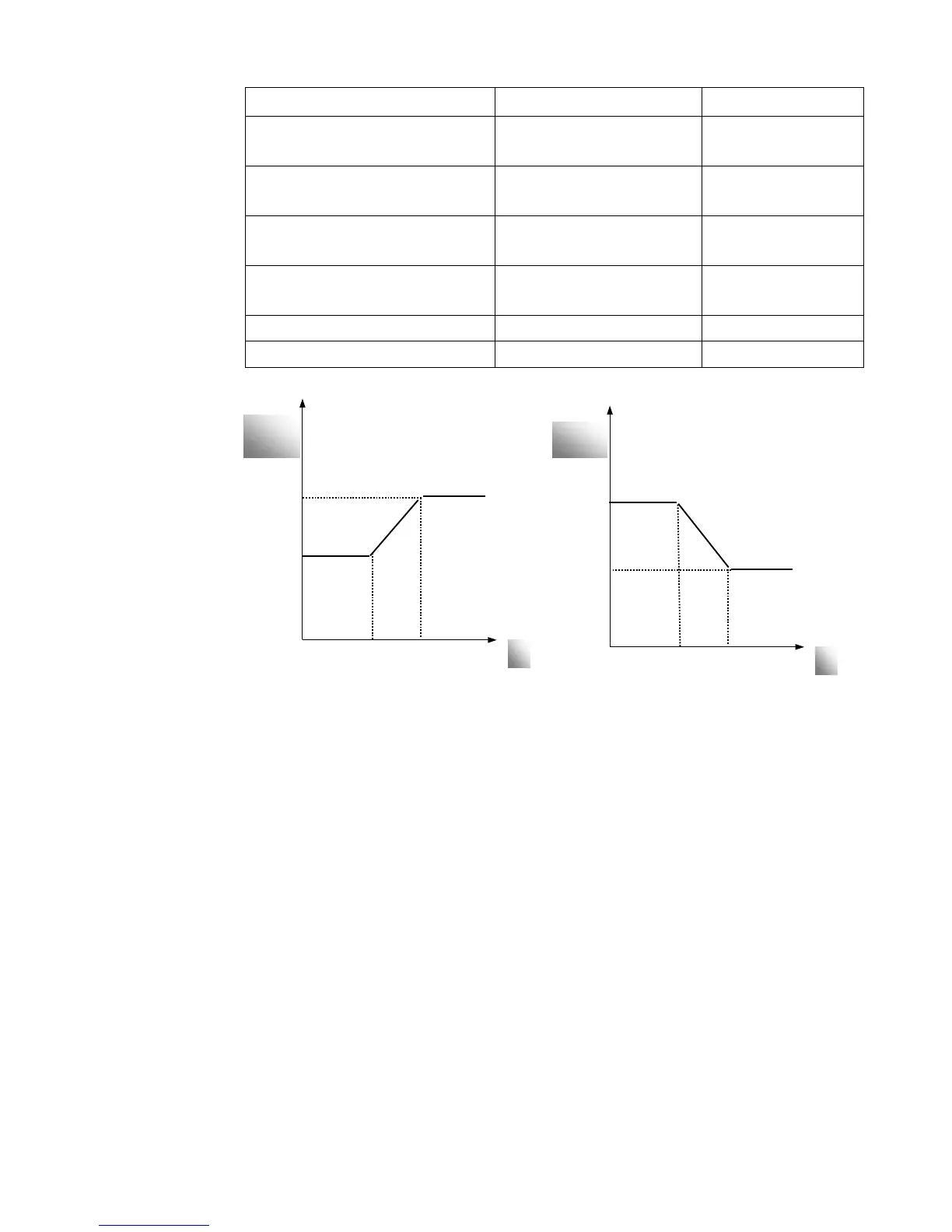

Figure 9-14 PID parameter

Dynamic response of vector control speed can be adjusted through adjusting gains of speed

loop. Increasing KP and KI can speed up dynamic response of speed loop. However, if

proportional gain or integral gain is too large, it may give rise to oscillation.

Recommended adjusting procedures:

Make fine adjustment of the value starting from the manufacturer value if the manufacturer

setting value cannot meet the needs of practical application. Be cautious that amplitude of

adjustment each time should not be too large.

In the event of weak loading capacity or slow rising of rotary speed, increase the value of KP

first under the precondition of ensuring no oscillation. If it is stable, increase the value of KI

properly to speed up response.

In the event of oscillation of current or rotary speed, decrease KP and KI properly.

In conditions of uncertainty, decrease KP at first, if there is no effect, increase KP. Then adjust

KI.

Note: Improper setting of KP and KI may result in violent oscillation of the system, or even

failure of normal operation. Set them carefully.

f

Loading...

Loading...