Operation and Simple Running 8-8

AC10 Inverter

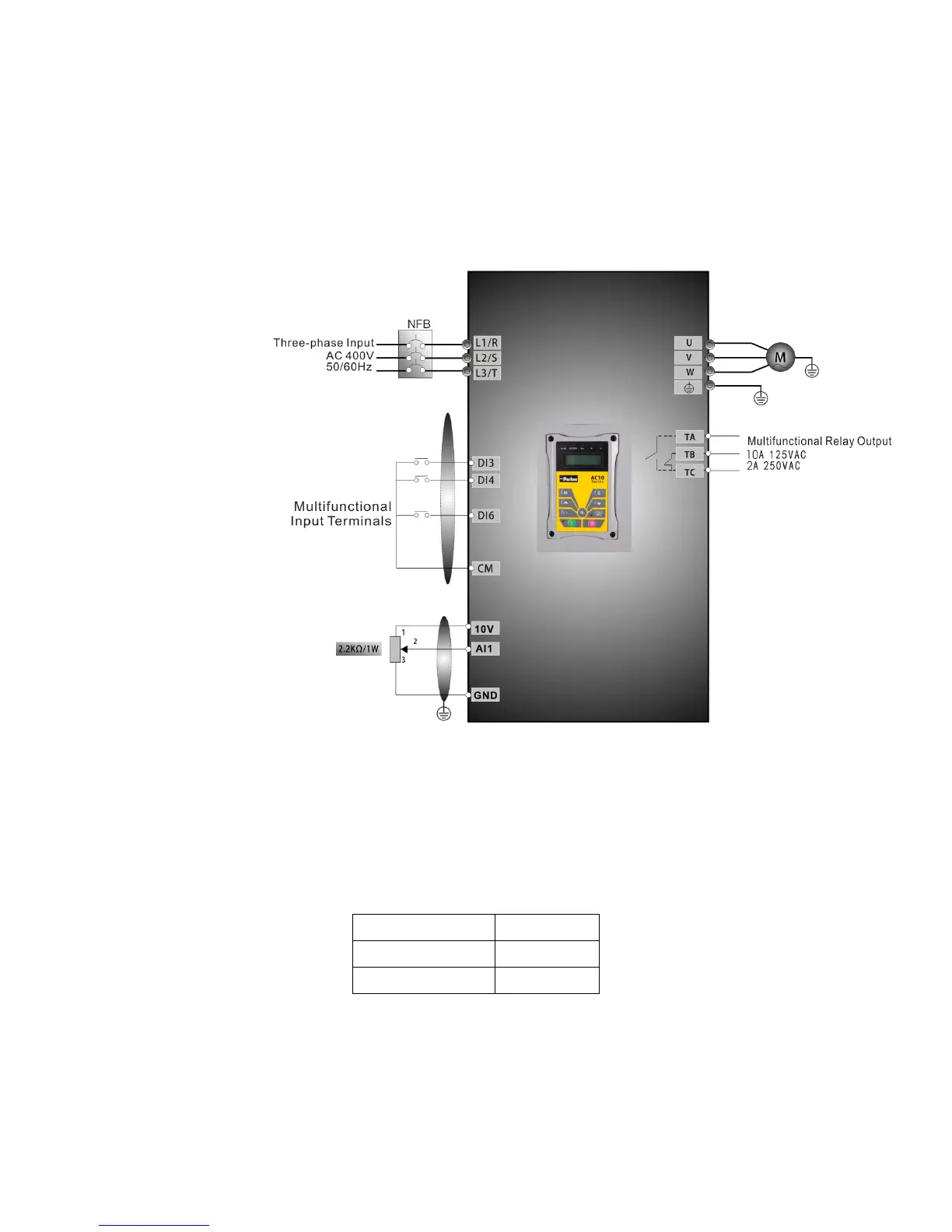

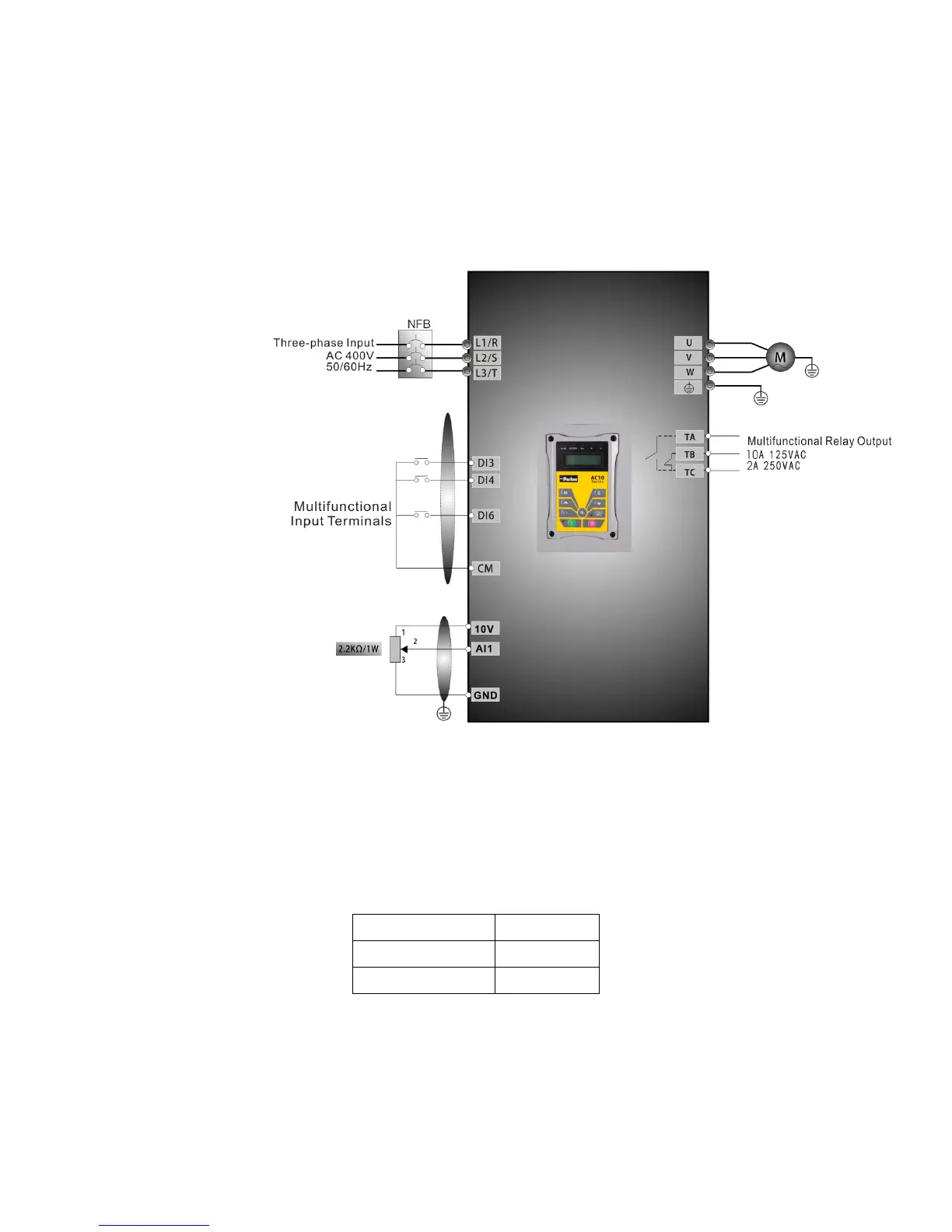

8.3.4 Setting the frequency with analog terminal and controlling the

operation with control terminals

i. Connect the wires in accordance with

Figure 8-3. After having checked the wiring

successfully, switch on the mains supply, and power on the inverter. Note: 2K~5K

potentiometer may be used for setting external analog signals. For the cases with

higher requirements for precision, a precise multiturn potentiometer is

recommended, and adopt shielded wire for the wire connection, with near end of

the shielding layer grounded reliably.

Figure 8-3 Wiring Diagram 3

ii. Press the “M” key, to enter the programming menu.

iii. Study the parameters of the motor: the operation process is the same as that of

example 1. (Refer to 8.3.1 for tuning of the motor).

iv. Set functional parameters of the inverter:

Function code Values

F203 1

F208 1

v. (5) There is a red two-digit coding switch SW1 near the control terminal block, as

shown in Figure 4-4. The function of coding switch is to select the voltage signal

(0~5V/0~10V) or current signal of analog input terminal AI2, current channel is

default. In actual application, select the analog input channel through F203. Turn

switches 1 to ON and 2 to ON as illustrated in the figure, and select 0~20mA

current speed control. Other switches state and mode of control speed are shown

in table

Table 8-2.

Loading...

Loading...