63

4. Install the piston ring on the piston and measure the clearance between the piston ring

and the piston ring groove with clearance gauge. If it does not conform to the specified

value, replace it.

Specified clearance: Top ring 0.02 ~ 0.06 mm

2

nd

ring 0.02~0.06 mm

Oil ring 0.04 ~ 0.18 mm

Inner diameter of connecting rod small end

Measure the inner diameter of small end. If the specified value is not met, replace it.

Inner diameter of small end: 15.985~15.998 mm

Connecting rod big-end backlash

Measure big-end backlash.If the specified value is not met, replace the connecting rod or crankshaft

or both.

Big-end backlash: 0.05~0.22 mm

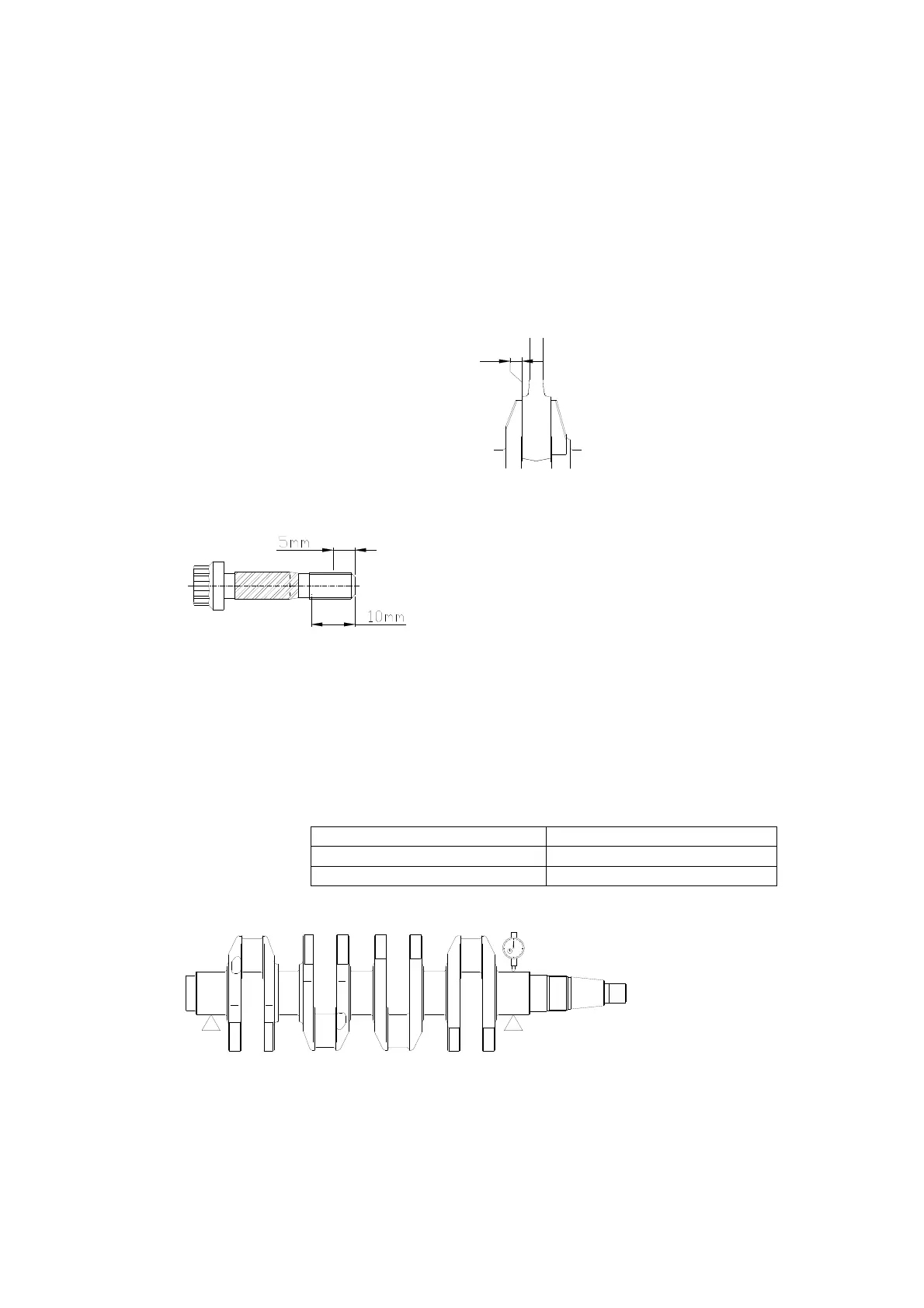

Check the connecting rod bolts

1. Check the thread diameter of the connecting rod bolt at the position shown.

2. Calculate the difference between the diameters of the two threads; If it does not

conform to the specified value, replace it.

Diameter difference of connecting rod bolt threads: 0~0.1 mm

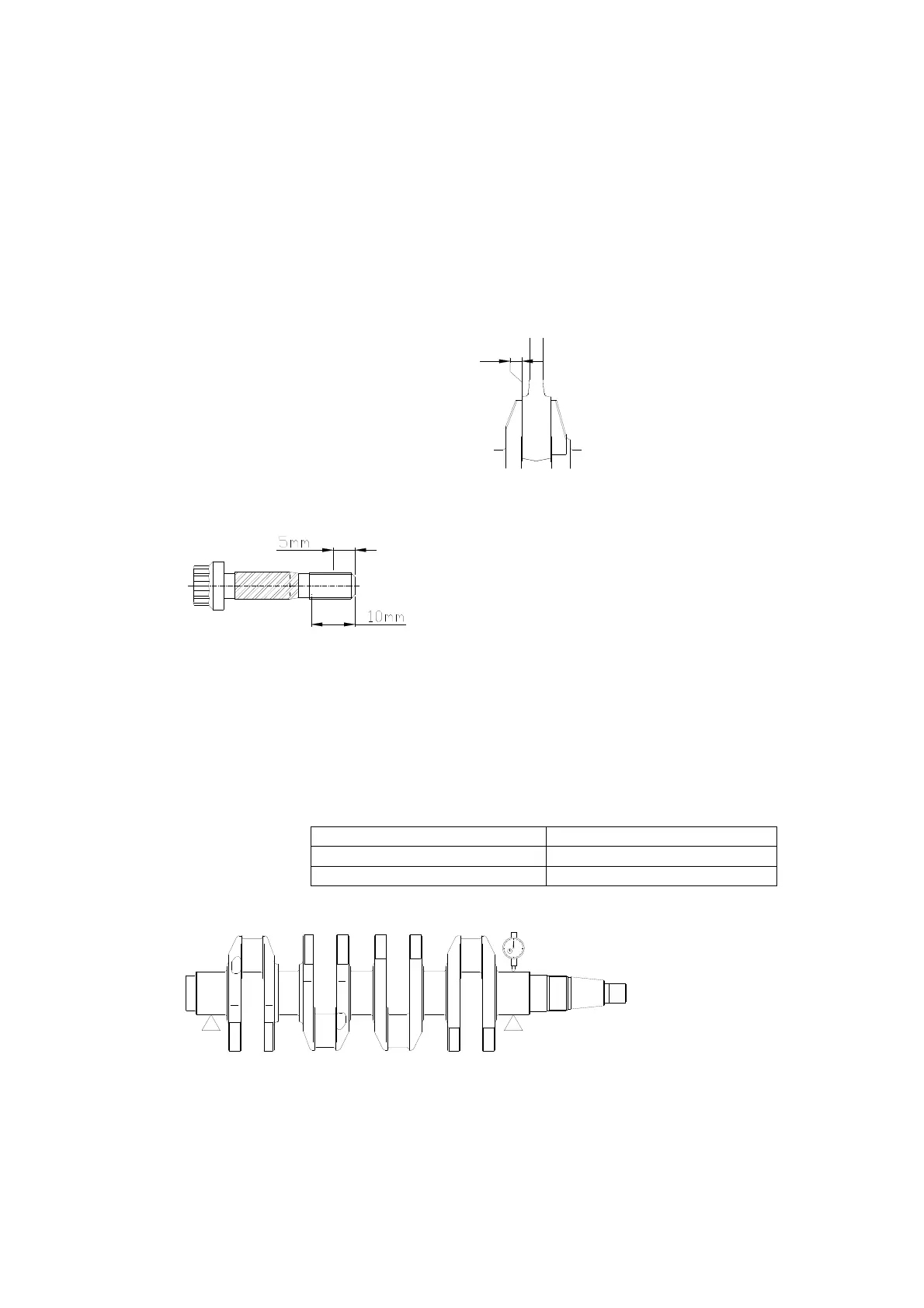

Crankshaft

1. Measure the crankshaft journal diameter, crank pin diameter and crank pin width. If the

specified value is not met, replace the crankshaft.

Crankshaft journal diameter 42.984~43.000 mm

Crank pin diameter 32.984~33.000 mm

Crank pin width 21.000~21.070mm

2. Check crankshaft runout; If the specified value is exceeded, replace it.

Crankshaft runout limit: 0.04mm

Clearance between crank pin and oil

1. Place a plastic clearance gauge on the crank pin and make it parallel to the crankshaft.

2. Fit the connecting rod and bearing bush on the crank pin.

3. Tighten the connecting rod bolts according to the specified torque.

a

Loading...

Loading...