5

BIFFI ICON 2000

InstructIon and operatIng manual

2.3 CHECKS TO BE PERFORMED BEFORE

INSTALLATION

•Makesurethevalvetobemotorizedisthe

appropriate one for coupling to the actuator.

•Theelectricalsupplycablesmustbesuitable

for the power rating (see the test certificate

that comes with the actuator).

•Gathertherighttoolsfortheassemblyand

for setting the actuator controls.

If a long storage period has occurred, before

reinstalling the actuator, please:

•CheckthestatusoftheO-ringseals.

•Checktheinstallationoftheplugsorcable

glands on the cable entries.

•Checkwhethertheenclosurecoversorthe

actuator body are cracked or broken.

•Checktheoillevelintheactuatorandtopup

if necessary.

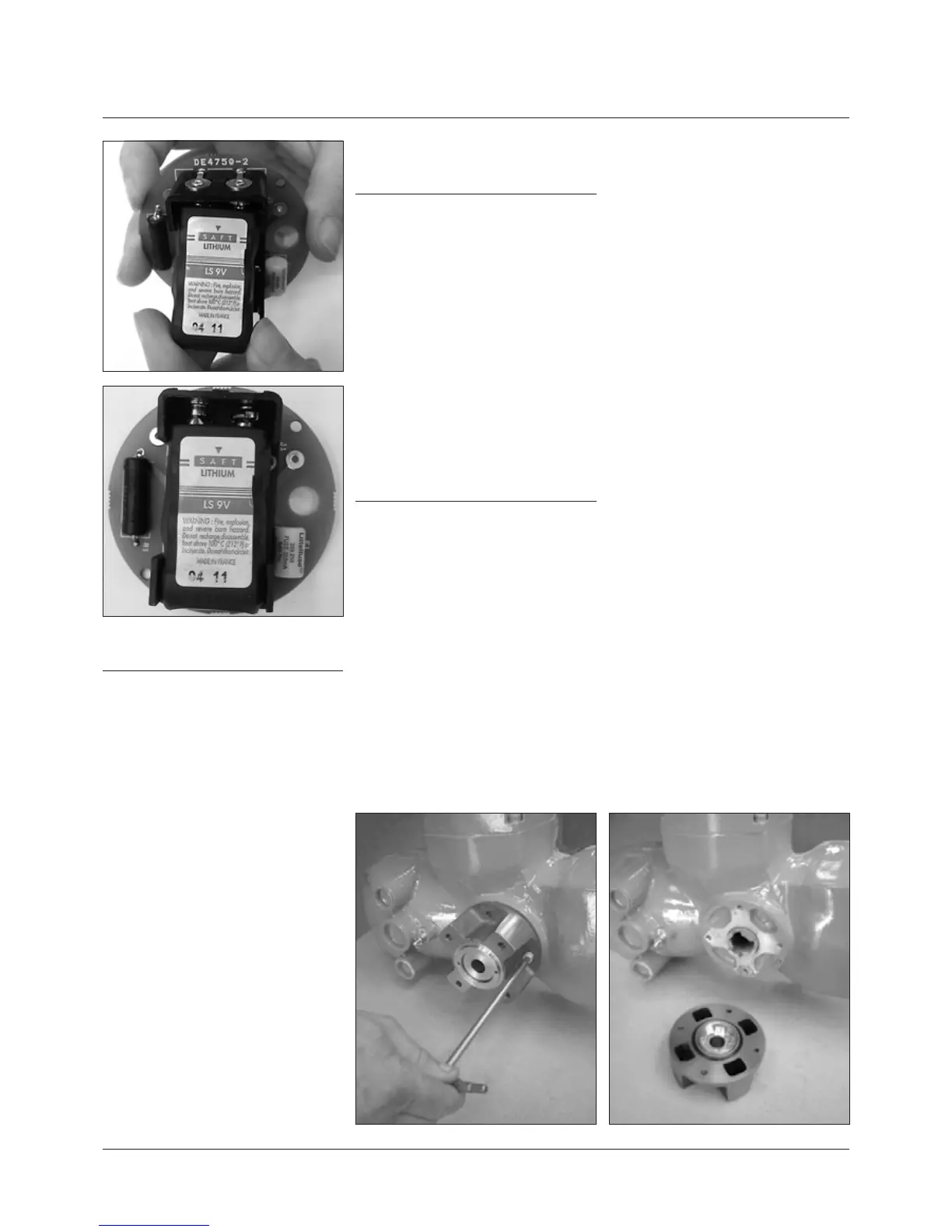

•Putthebatteriesbackintoplace

(see paragraph 11.3, Maintenance - Lithium

battery change).

3. INSTALLATION

3.1 WORKING CONDITION

The standard actuators are suitable for the

following environment temperatures:

-30°C +85°C (-22°F to +185°F)

Special versions are available for extreme

environment temperatures:

-40°C +70°C (-40°F to +158°F)

-55°C +70°C (-67°F to +158°F)

Note: only for Ex d or Ex d e versions, for

ambient temperature range, see the specific

attached addendum.

IMPORTANT

Check the "temperature environment range"

embossed on the nameplate, for the correct

utilisation with respect to the environment

temperature.

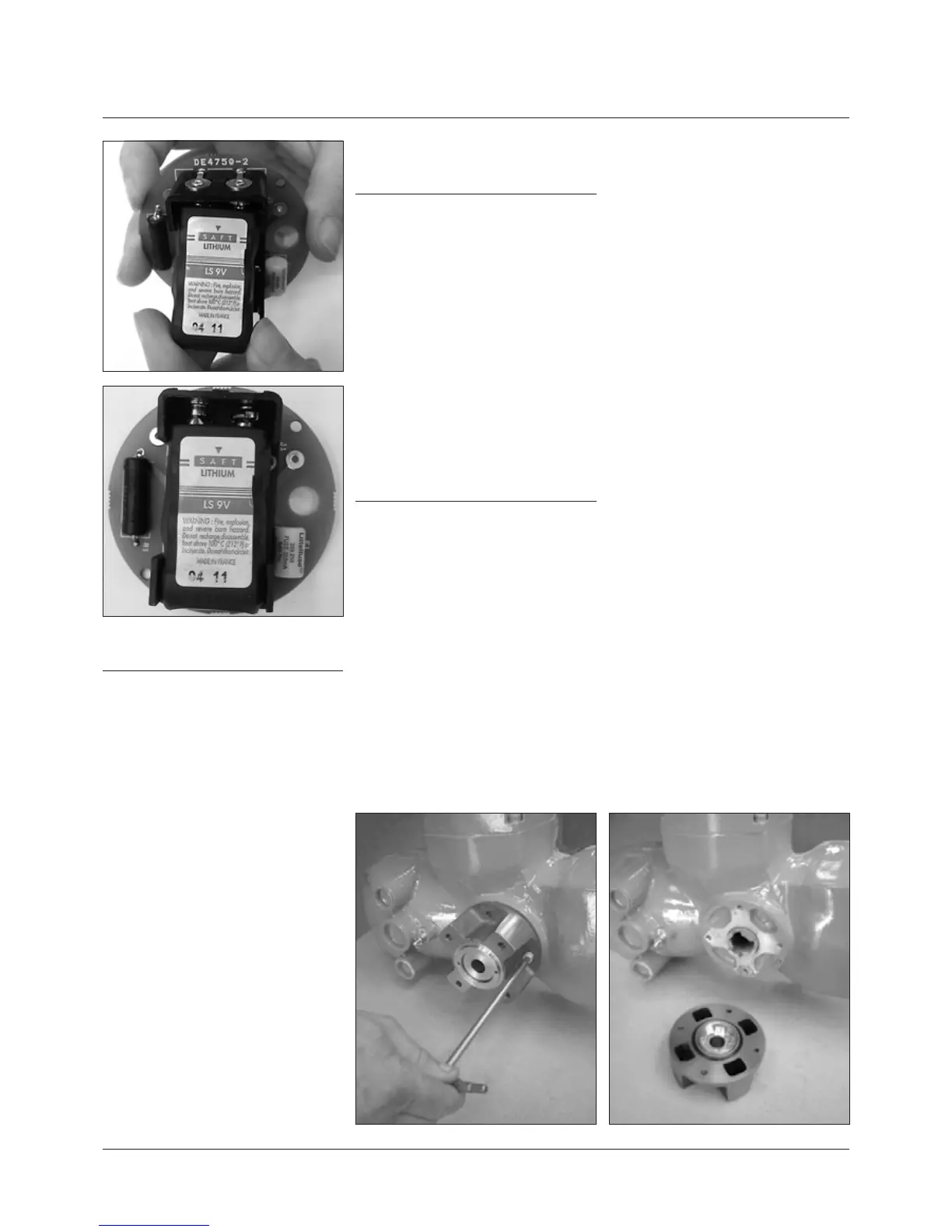

3.2 COUPLING BLOCK: DISASSEMBLY FROM

THE ACTUATOR

The bushing is delivered already assembled to

the drive sleeve, even when it is unmachined.

In order to perform the necessary machining,

remove the bushing from its housing. Remove

the fixing screws from the coupling block.

Actuator view from the coupling side, with the

block separated from the gearbox. Do not lose

the seal ring between the coupling block and

the gear reduction unit.

Loading...

Loading...