Adjustment

13 - 23

Fig. 13 - 21

2

2

1

0

4

-0

1

7

1

4

3

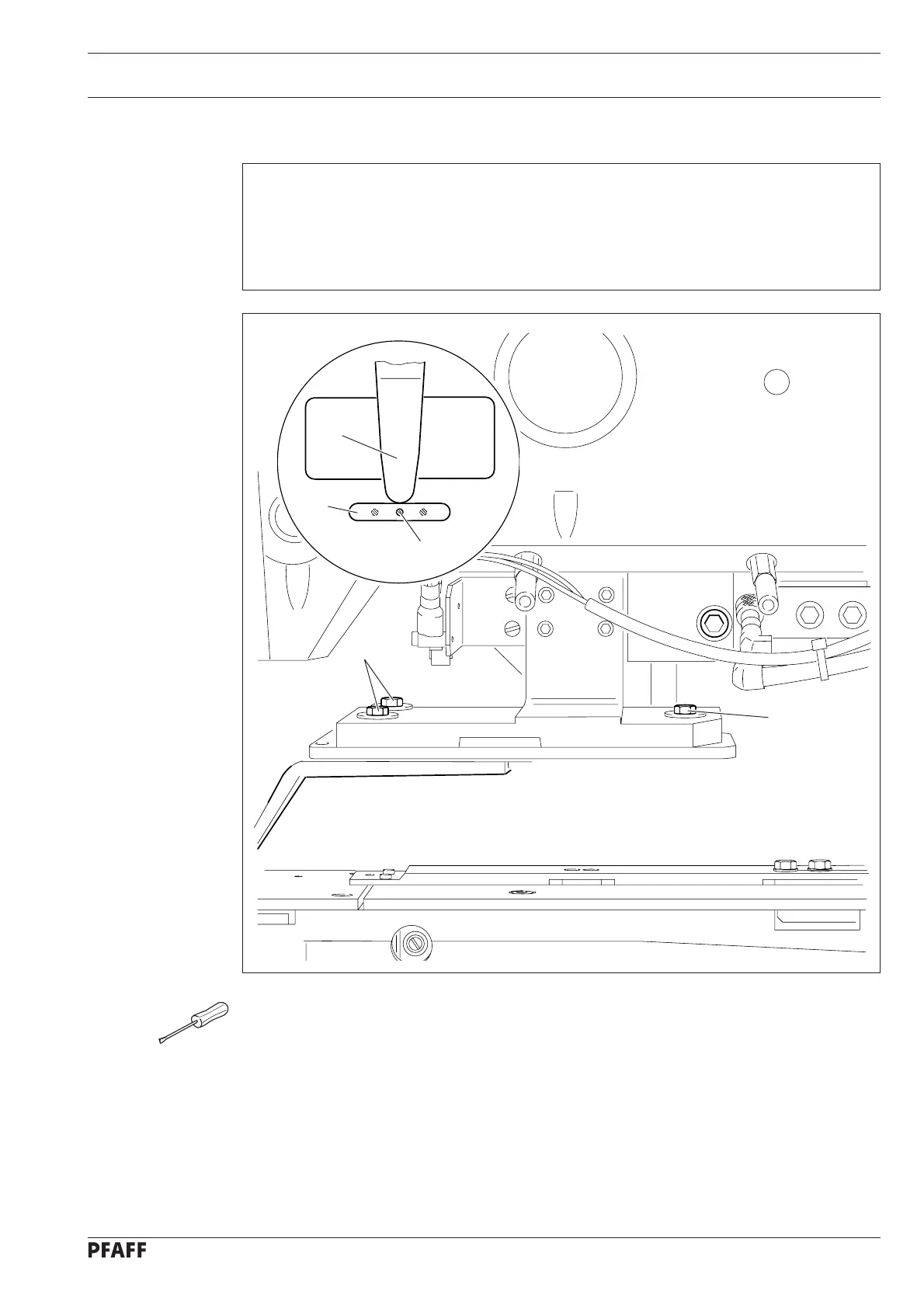

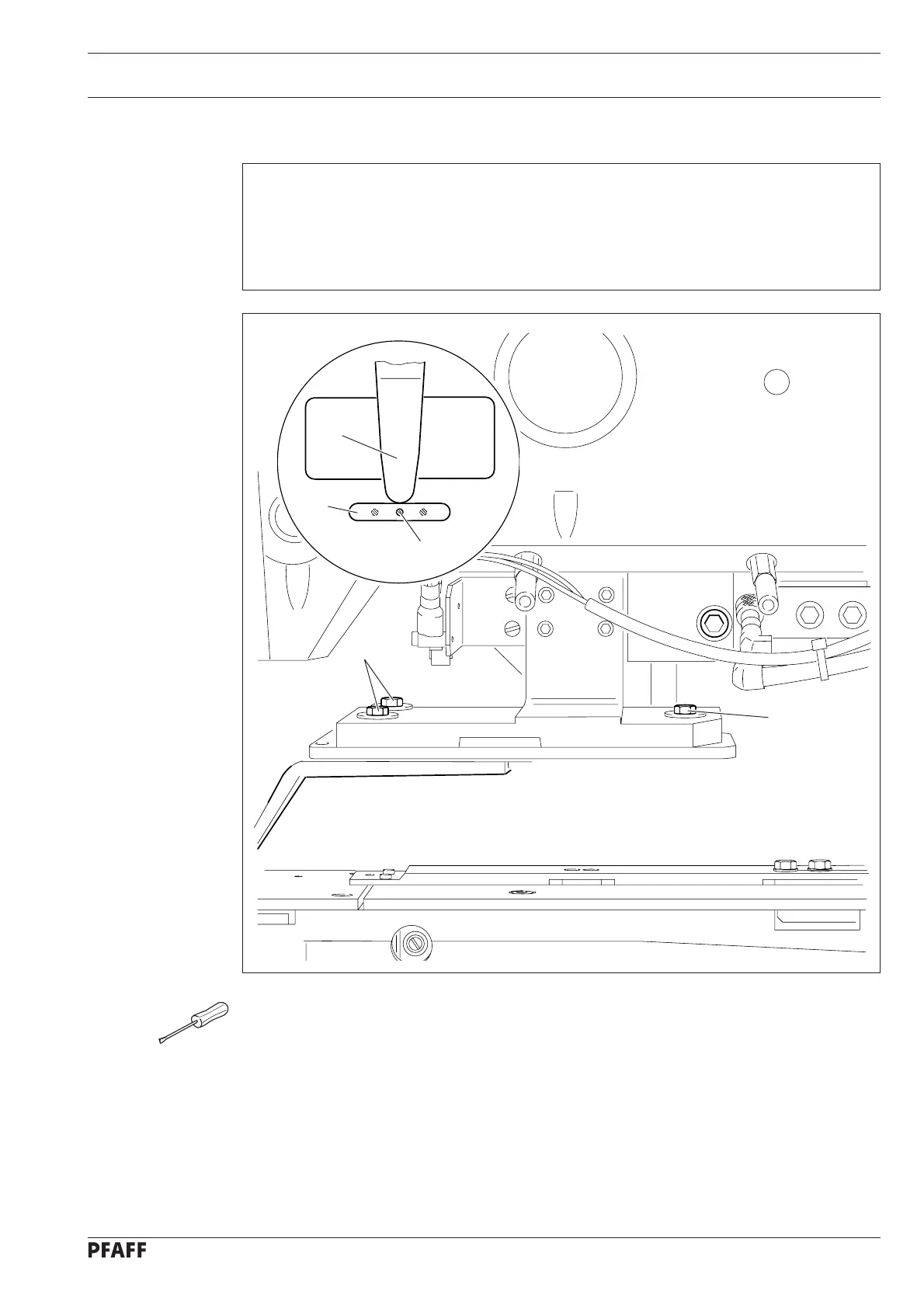

13.23 Aligning the work clamp (only on subclass -4/..)

Requirement

1. After selecting value "4" for parameter "610", work clamp 1 should be centred to the

needle and be positioned at the front edge of the needle hole.

2. When value "6" is set, needle 3 should be positioned to the left of work clamp 1, and

when value "7" is set, needle 3 should be positioned to the right of it.

● Switch on the machine and set parameter "610" at "4" (button gauge: centre).

● Push down work clamp 1 by hand.

● Adjust work clamp 1 (screws 2) in accordance with requirement 1.

● Check the other needle entry positions for values "6" and "7" of parameter "610" in

accordance with requirement 2.

● Connect the machine to the pneumatic power supply and check the setting again.

● If necessary correct the position of work clamp 1 (screws 2).

● Switch off the machine and disconnect it from the pneumatic power supply.

Loading...

Loading...