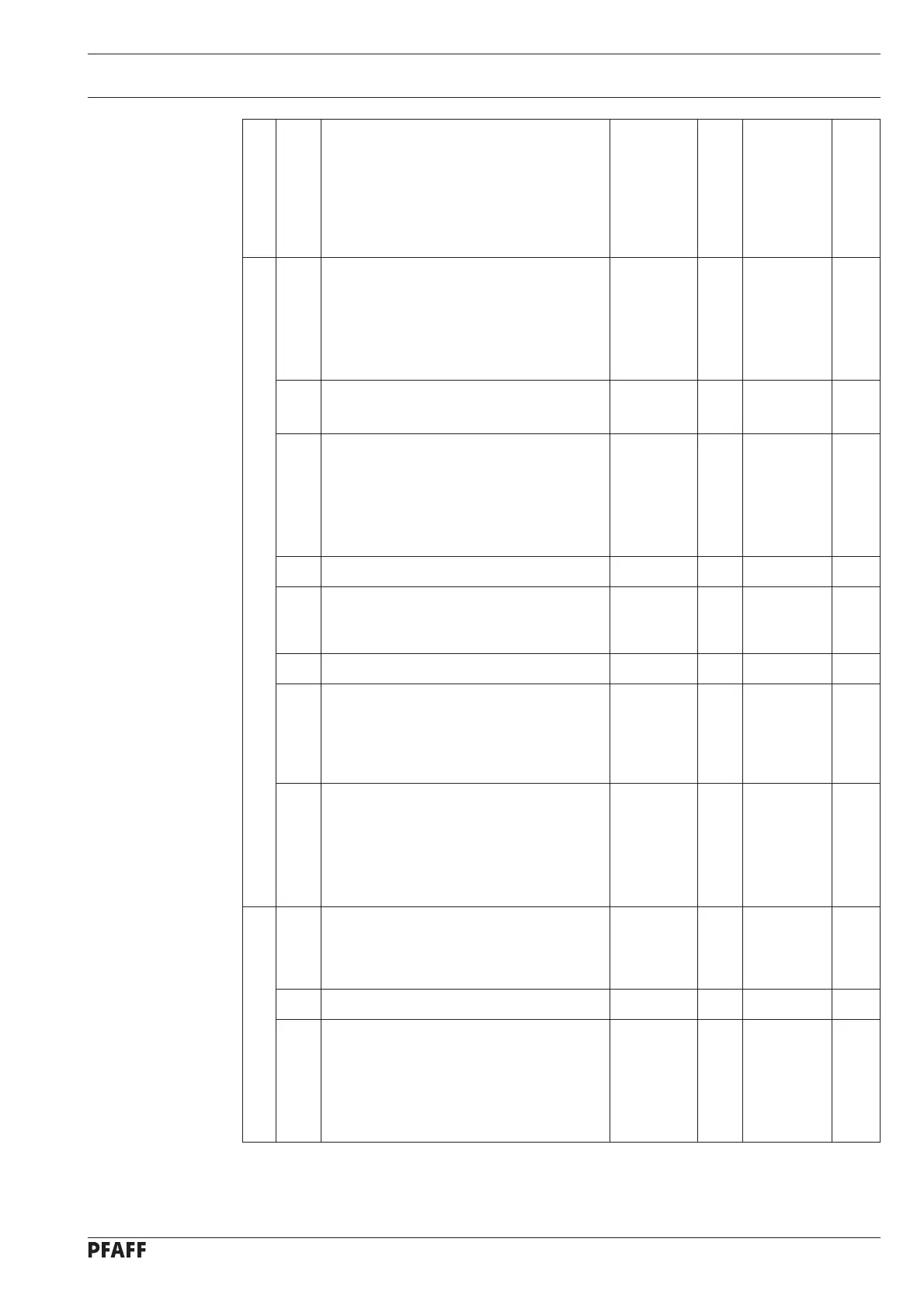

P40 ED Input

41

Group

Parameter

Description

Machine type

User level

Setting range

Set value

7

774 Needle position raised for thick

material(with pedal)

ON = t.d.c. needle (parameter 710)

OFF = t.d.c. thread take-up lever

(parameter 703)

1, 2, 3, 4, 5 B ON - OFF OFF

775 Stop time for ornamental tack [ms] 1, 3, 4, 5,

2

B

B

10 - 1000

10 - 1000

100

150

782 Needle position raised for thick

material(with key on machine head)

ON = t.d.c. needle (parameter 710)

OFF = t.d.c. thread take-up lever

(parameter 703)

1, 2, 3, 4, 5 B ON - OFF OFF

789 Needle position 10 (bearing position) 1, 2, 3, 4, 5 B 0 - 255 248

793 Delay for feed adjustment on till trim-

ming with shortened trim stitch [ms)

1

2, 3, 4, 5,

B

-

0 - 2000

-

140

-

797 Hardware test 1, 2, 3, 4, 5 C ON - OFF OFF

798 User level

0 = user level A

1 = mechanic level B

11 = service level C

1, 2, 3, 4, 5 B 0 - 20 0

799* Selected machine class(see Table of

machine types on Page 34)

1

2

3

4

5

C

C

C

C

C

1

2

3

4

5

1

2

3

4

5

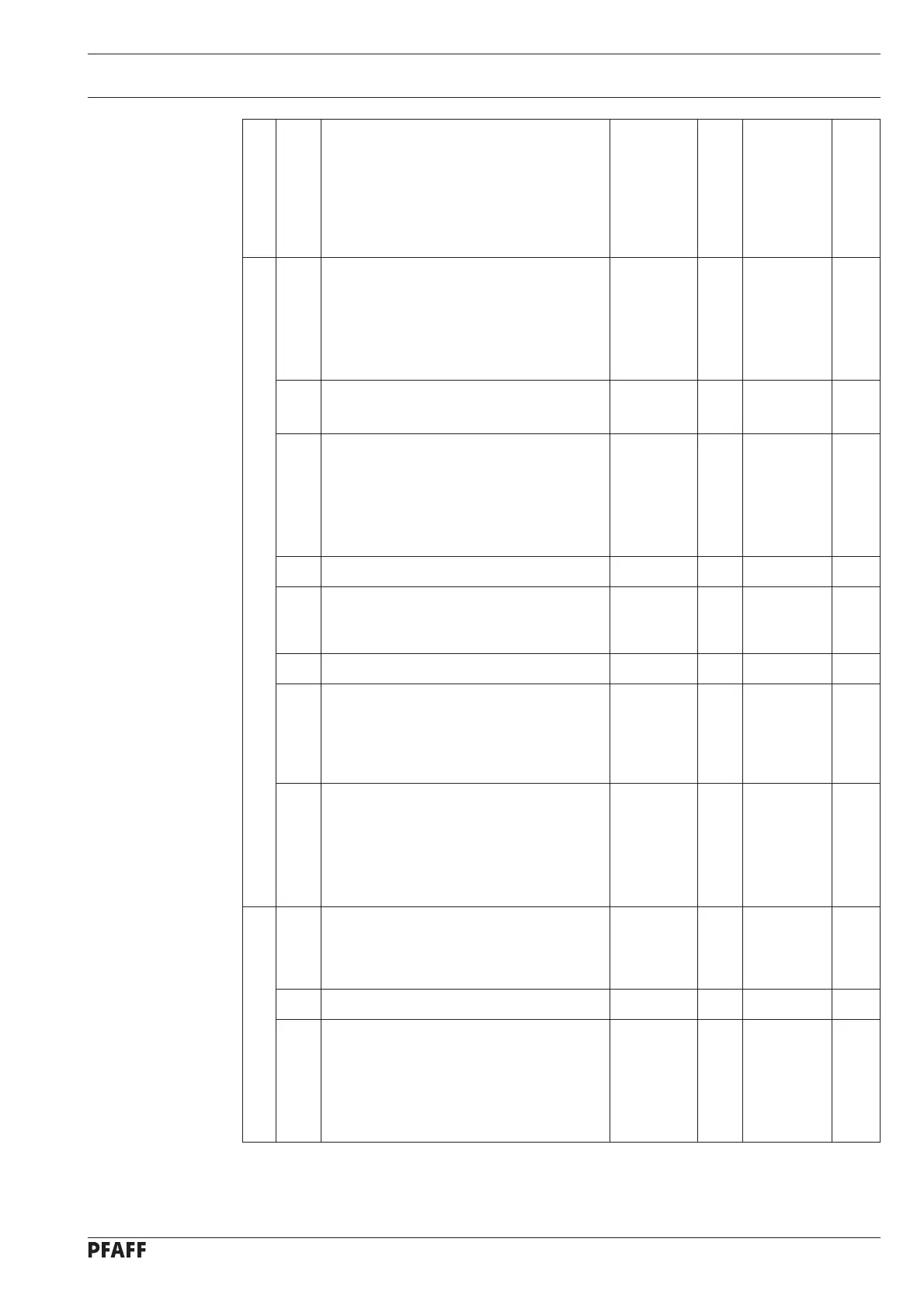

8

800* Motor rotating direction when looking

at V-belt pulley

1= anti-clockwise, 0 = clockwise

1, 5

2, 3, 4, ,

C

C

0 - 1

0 - 1

0

1

801 Reversing angle at end of seam 1, 2, 3, 4, 5 B 10 - 212 32

814 Change-over of positioning method

1 = Ramp braking in target position

2 = Max. braking at positioning speed

and wait till target position is

reached.

1, 2, 3, 4, 5 C 1 - 2 1

* = These parameters remain unchanged when the set parameter values are reset,

see Chapter 10.01 Reset / Cold start.

Loading...

Loading...